Preparing process of dried multi-flavor eggs

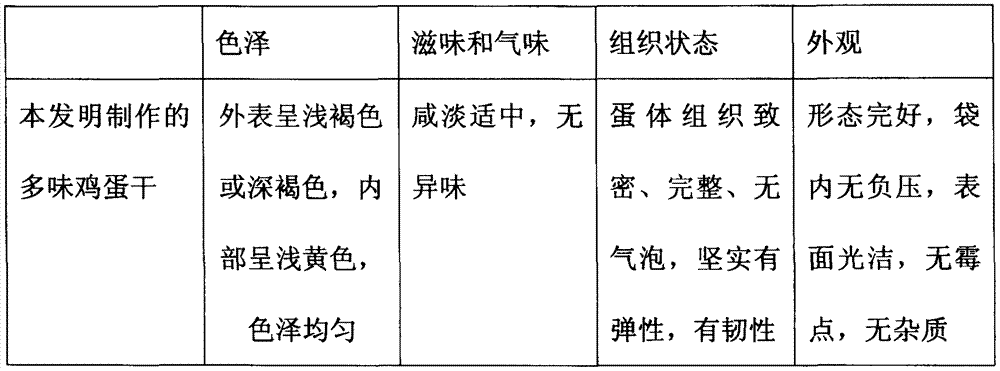

A production process, a technology for dried eggs, applied in the field of production technology of multi-flavored dried eggs, can solve the problems of backward processing methods of dried eggs, need to be improved in quality and appearance, single taste of dried eggs, etc., achieves thorough cleaning and disinfection, and protects the liver. , the effect of many flavors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A process for making multi-flavored dried eggs, comprising the following steps:

[0017] (1) cleaning, disinfecting, testing, and egg breaking all-in-one machine device for cleaning, sterilizing and shelling fresh native eggs, then taking egg white and egg yolk, stirring evenly to obtain native egg liquid;

[0018] (2) Add sugar, salt, sodium glutamate and soy sauce to the native egg liquid, stir evenly, pour it into a mold, cook at a high temperature of 120°C and a high pressure of 3.0Mpa for 20 minutes, remove the mold, and put it in a brine for marinating; The mass percent of each raw material is: 99.5% of native egg liquid, 0.2% of sugar, 0.1% of salt, 0.1% of sodium glutamate, and 0.1% of soy sauce; 10.5 parts of soy sauce, 0.5 parts of cooking wine, 0.3 parts of sesame oil, 0.2 parts of cumin, 0.6 parts of cinnamon, 0.3 parts of bay leaf, 80 parts of water;

[0019] (3) Drying with a multi-layer drying device, then packaging, sterilization, cooling, inspection, a...

Embodiment 2

[0021] A process for making multi-flavored dried eggs, comprising the following steps:

[0022] (1) cleaning, disinfecting, testing, and egg breaking all-in-one machine device for cleaning, sterilizing and shelling fresh native eggs, then taking egg white and egg yolk, stirring evenly to obtain native egg liquid;

[0023] (2) Add sugar, salt, sodium glutamate and soy sauce to the native egg liquid, stir evenly, pour it into a mold, cook at a high temperature of 125°C and a high pressure of 2.5Mpa for 15 minutes, remove the mold, and put it into the brine for marinating; The mass percentage of each raw material is: 99.5% of egg liquid, 0.2% of sugar, 0.1% of salt, 0.1% of sodium glutamate, and 0.1% of soy sauce. The brine comprises by weight: 0.75 parts of sugar, 6.5 parts of table salt, 9.5 parts of soy sauce, 0.8 parts of cooking wine, 0.4 parts of sesame oil, 0.3 parts of cumin, 0.5 parts of cinnamon, 0.4 parts of bay leaves, water, and 100 parts.

[0024] (3) Drying with a...

Embodiment 3

[0026] A process for making multi-flavored dried eggs, comprising the following steps:

[0027] (1) cleaning, disinfecting, testing, and egg breaking all-in-one machine device for cleaning, sterilizing and shelling fresh native eggs, then taking egg white and egg yolk, stirring evenly to obtain native egg liquid;

[0028] (2) Add sugar, salt, sodium glutamate and soy sauce to the native egg liquid, stir evenly, pour it into a mold, cook at a high temperature of 130°C and a high pressure of 3.0Mpa for 10 minutes, remove the mold, and put it in a brine for marinating; The mass percentage of each raw material is: 99.5% of egg liquid, 0.2% of sugar, 0.1% of salt, 0.1% of sodium glutamate, and 0.1% of soy sauce. The brine comprises by weight: 0.85 parts of sugar, 5.5 parts of table salt, 10.5 parts of soy sauce, 1.0 part of cooking wine, 0.5 parts of sesame oil, 0.2 parts of cumin, 0.6 parts of cinnamon, 0.3 parts of bay leaves and 100 parts of water.

[0029] (3) Drying with a mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com