UPS automatic heating circuit

An automatic heating and circuit technology, applied in the field of UPS, can solve the problems of increasing labor costs, reducing use efficiency, shortening battery discharge time, etc., to achieve the effect of extending backup time, improving life, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

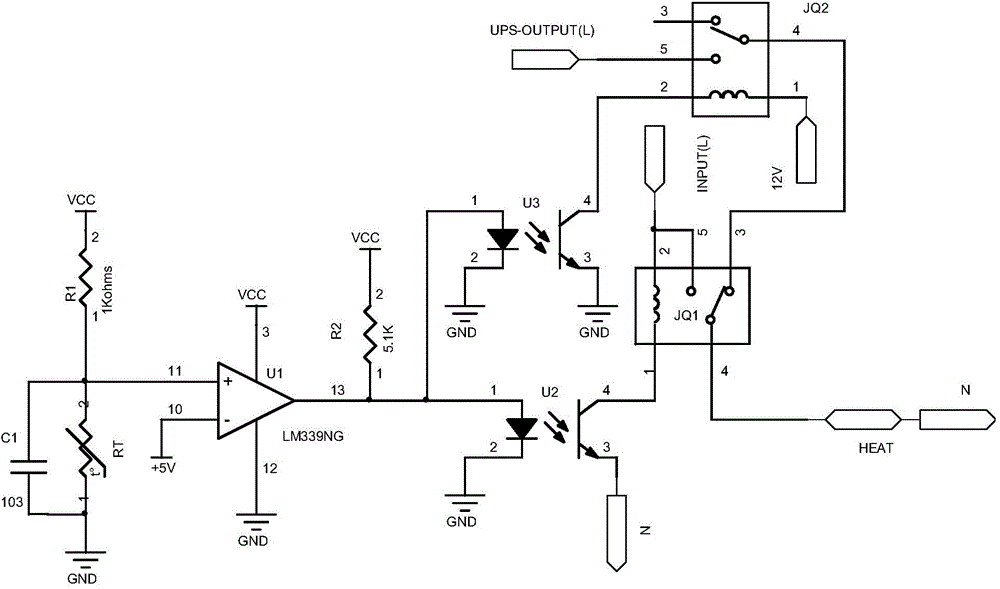

[0020] refer to figure 1 , UPS automatic heating circuit described in the present invention, it comprises temperature detection and voltage divider circuit, comparison circuit, heating cut-off circuit and heating device, wherein, temperature detection and voltage divider circuit are connected with comparison circuit, for according to outside temperature Change the resistance value to generate different voltage values and transmit them to the comparison circuit. The comparison circuit is connected with the temperature detection and voltage divider circuit and the heating cut-off circuit, and is used to compare the voltage value of the temperature detection and voltage divider circuit with the preset value, and transmit the high and low level signals to the heating cut-off circuit. The heating cut-off circuit is connected with the comparison circuit and the heating device, and is used to receive the high and low level signals transmitted by the comparison circuit, and control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com