Integral Flaw Detection Method of Aluminum Alloy Impeller

An aluminum alloy impeller, integral technology, applied in the direction of using radiation for material analysis, etc., can solve the problem of integral flaw detection of impellers that cannot be closed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

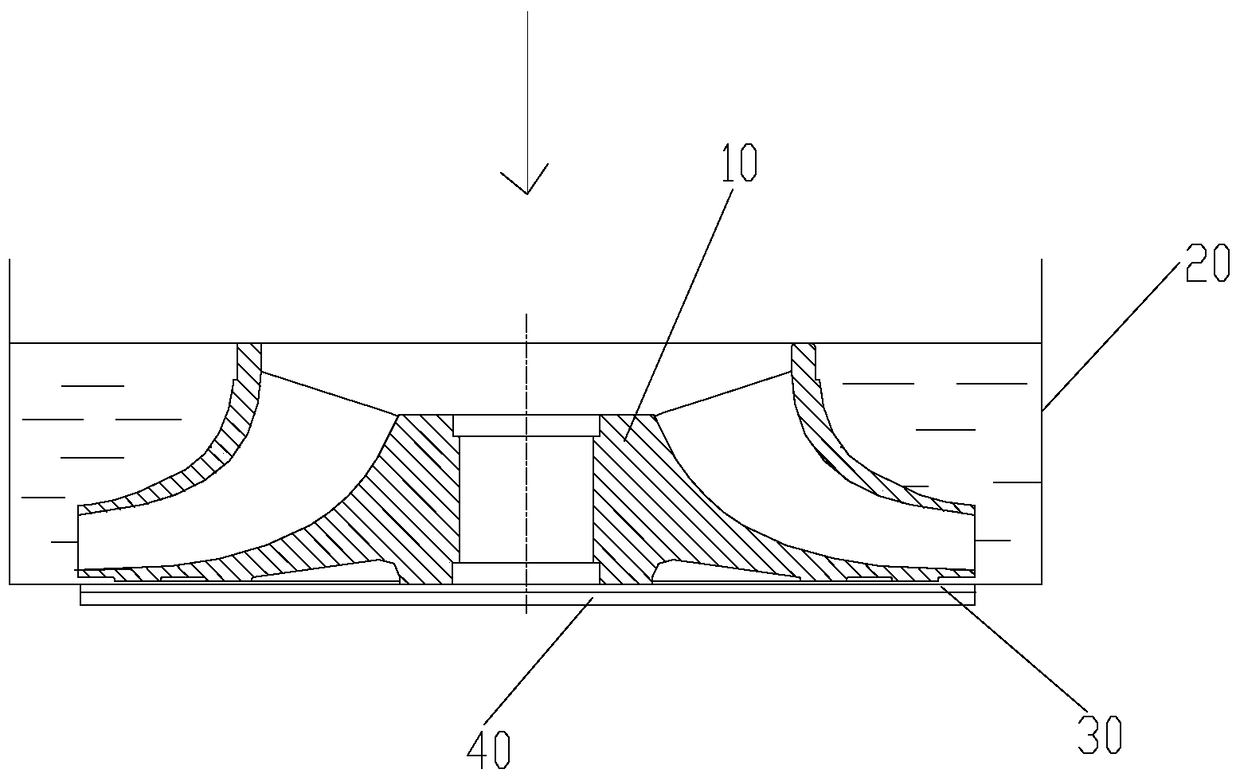

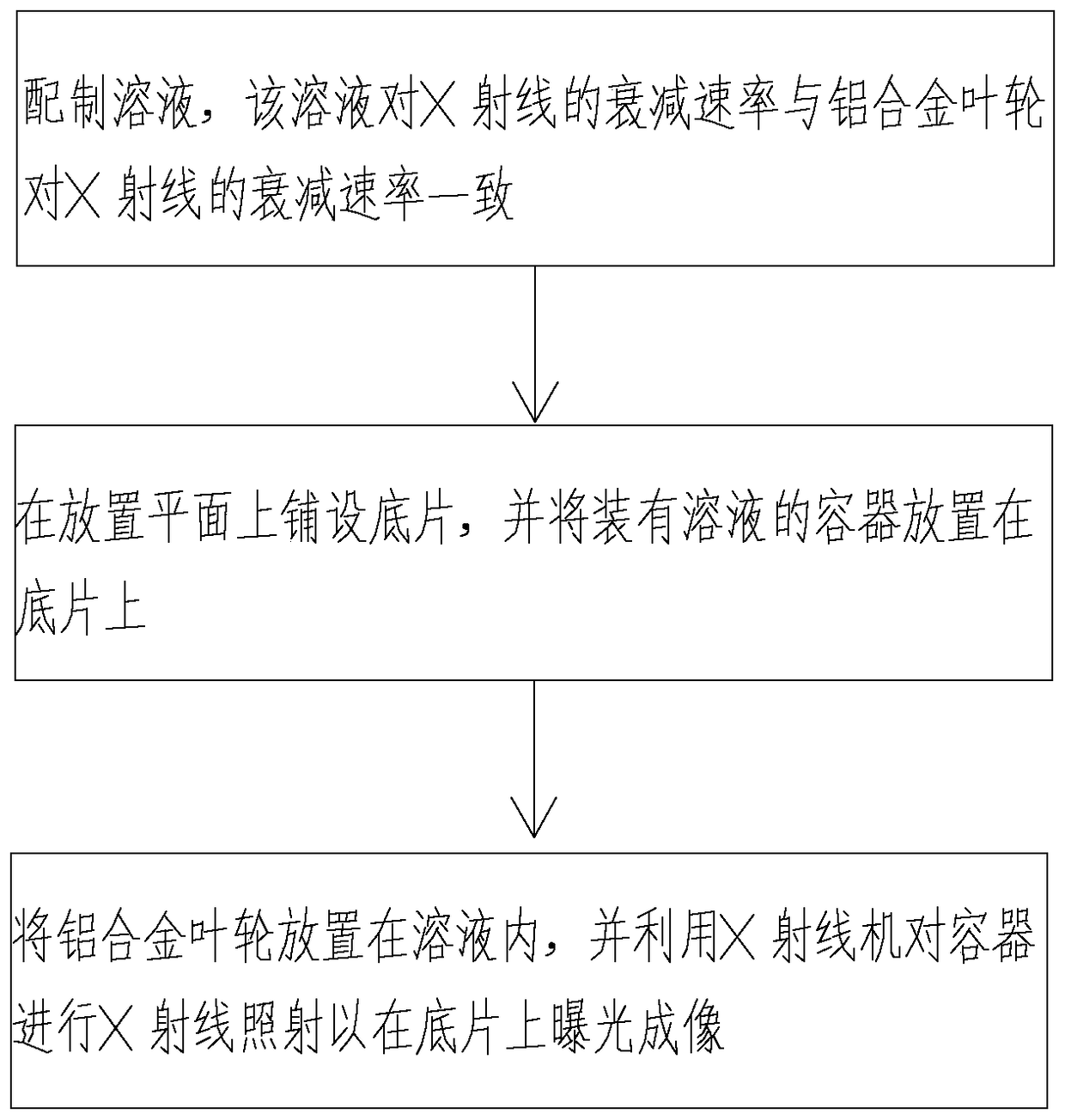

[0023] see figure 1 and figure 2 as shown, figure 2 The direction of the arrow in is the irradiation direction of X-rays. According to an embodiment of the present invention, a method for overall flaw detection of an aluminum alloy impeller is provided. The overall flaw detection method of the aluminum alloy impeller includes: step S1: preparing a solution, the attenuation rate of the solution to X-rays is consistent with that of the aluminum alloy impeller 10 to X-rays; step S2: laying the negative film 30 on the placement plane, and The container 20 with the solution is placed on the negative film 30 ; step S3 : place the aluminum alloy impeller 10 in the solution, and use an X-ray machine to irradiate the container 20 with X-rays to expose a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com