Universal inspection device and method for multi-model automobile front-row seats

A technology for automobile front seats and an inspection device, which is applied in the field of automobile seat manufacturing, can solve the problems of increasing production costs, waste of resources, etc., and achieves the effects of not causing waste of resources, improving versatility, and reducing costs and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

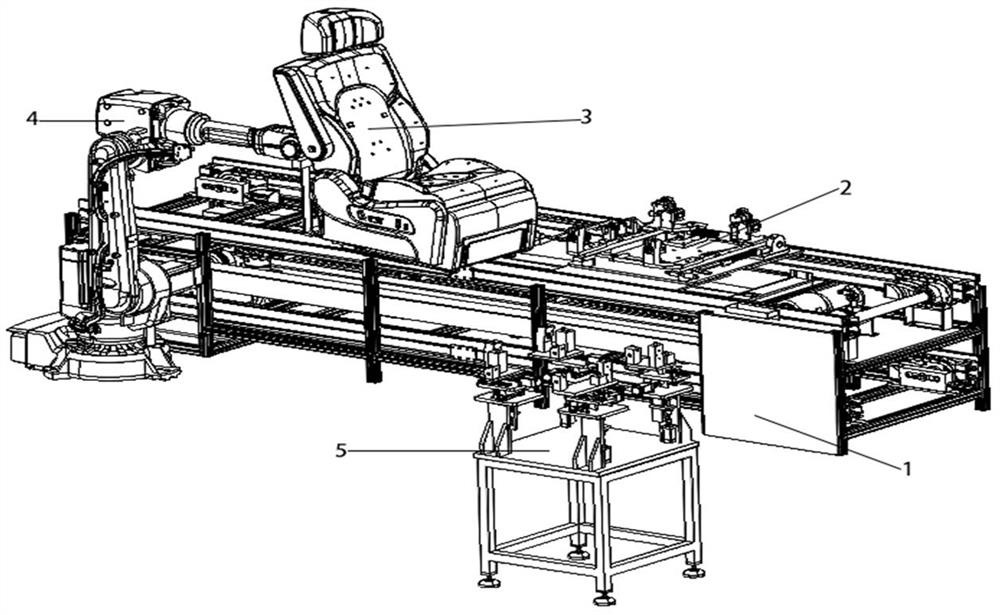

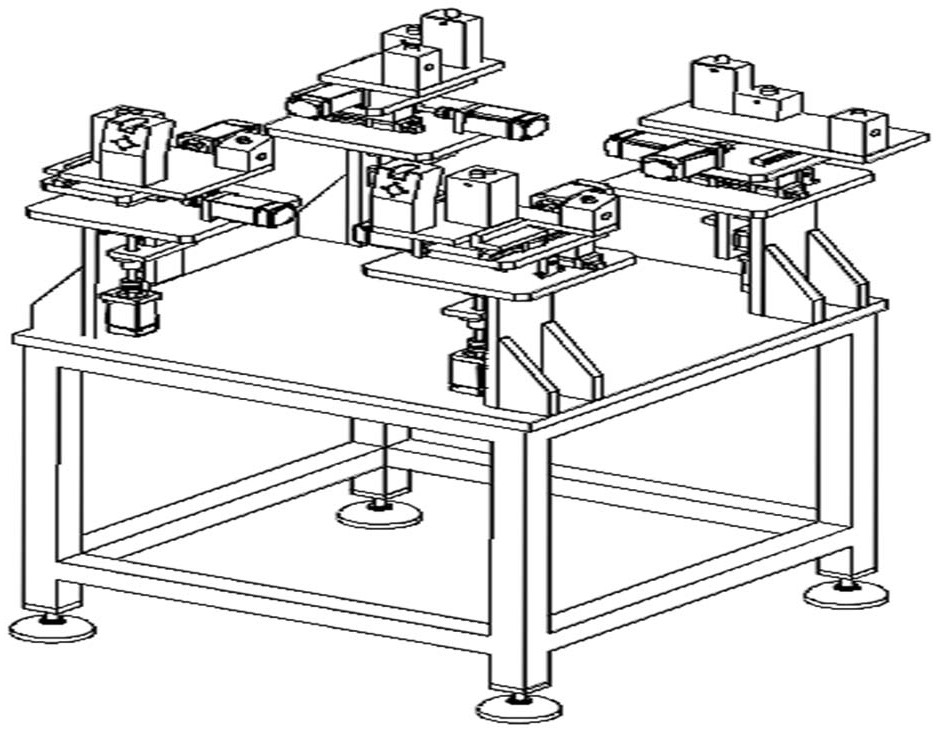

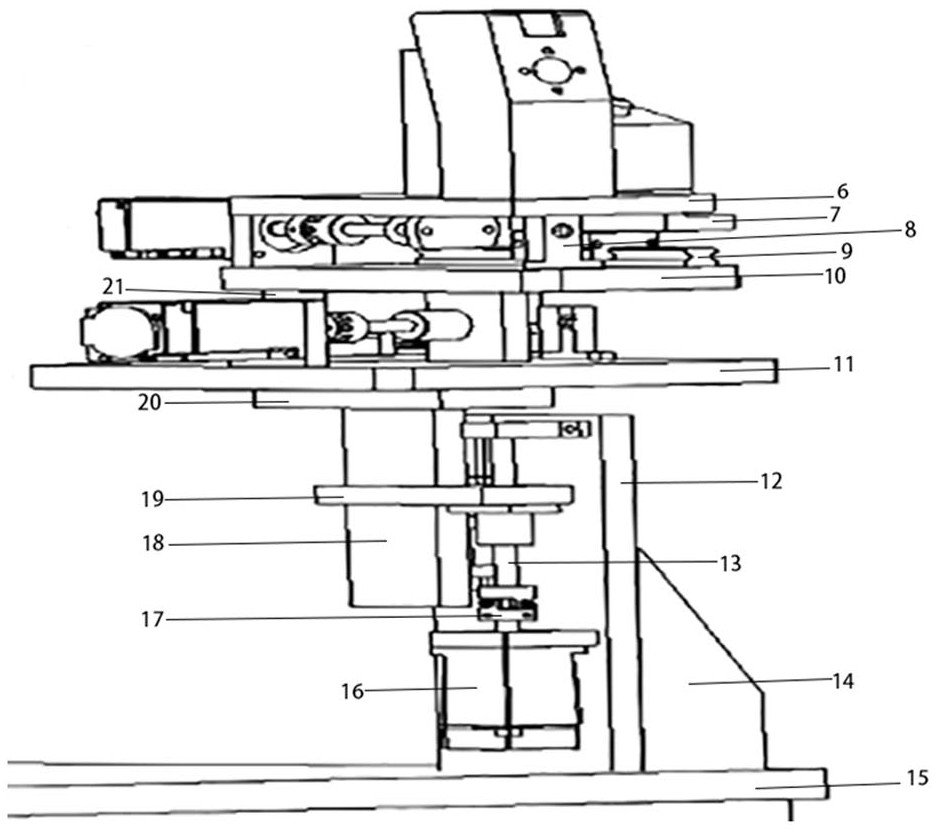

[0027] Such as figure 1 As shown, the present embodiment provides a multi-type automobile front seat universal inspection device, including a production line 1, a jig plate 2, a checking tool 5 and a control system, and the jig plate 2 is installed on the production line and can be installed on the production line. Move back and forth on it to place the assembled seat 3 and transport it to the end station of the production line 1, the bottom of the jig tray 2 is provided with an RFID card, and the end station of the production line 1 is provided with an RFID card scanner. The checking tool 5 is provided with several positioning blocks that cooperate with the bottom of the seat 3 to fix the seat. Each positioning block is installed on the checking tool 5 through the moving mechanism to change the positioning position under the driving of the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com