A self-calibrating real-time temperature measurement device for thin film growth

A temperature measurement device and thin film growth technology, applied in measurement devices, optical radiation measurement, radiation pyrometry, etc., can solve the problems of temperature deviation, epitaxial wafer growth temperature measurement cannot be guaranteed to be consistent and accurate, and achieve consistent measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] see attached figure 1 , the self-calibration real-time temperature measurement device for thin film growth provided by the present invention includes an actual thermal radiation ratio acquisition unit and a calibration coefficient calculation unit,

[0057] The actual heat radiation ratio obtaining unit is used to obtain the actual heat radiation ratio;

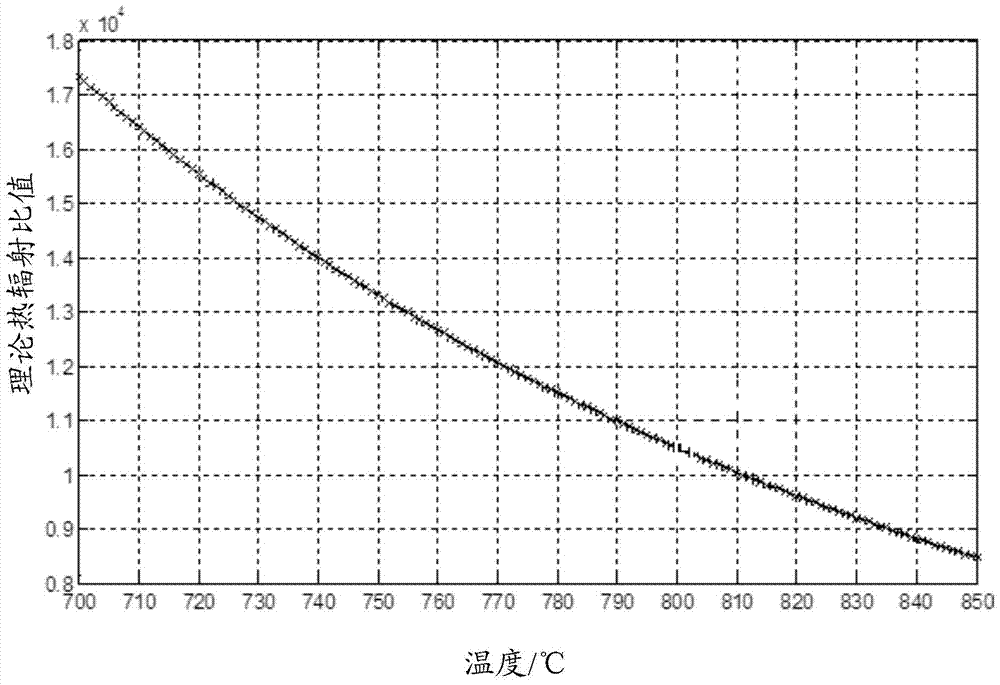

[0058] According to the actual heat radiation ratio, the calibration coefficient calculation unit is figure 2 On the shown theoretical heat radiation ratio-temperature curve, draw a point corresponding to the actual heat radiation ratio, and substitute the value of the temperature T corresponding to this point into

[0059]

[0060]

[0061] get the calibration coefficient m respectively 1 and m2 ; the actual heat radiation ratio is the appendix figure 2 The ordinate of the shown theoretical heat radiation ratio-temperature curve, a point can be directly traced on the curve from the ordinate, and the absciss...

Embodiment 2

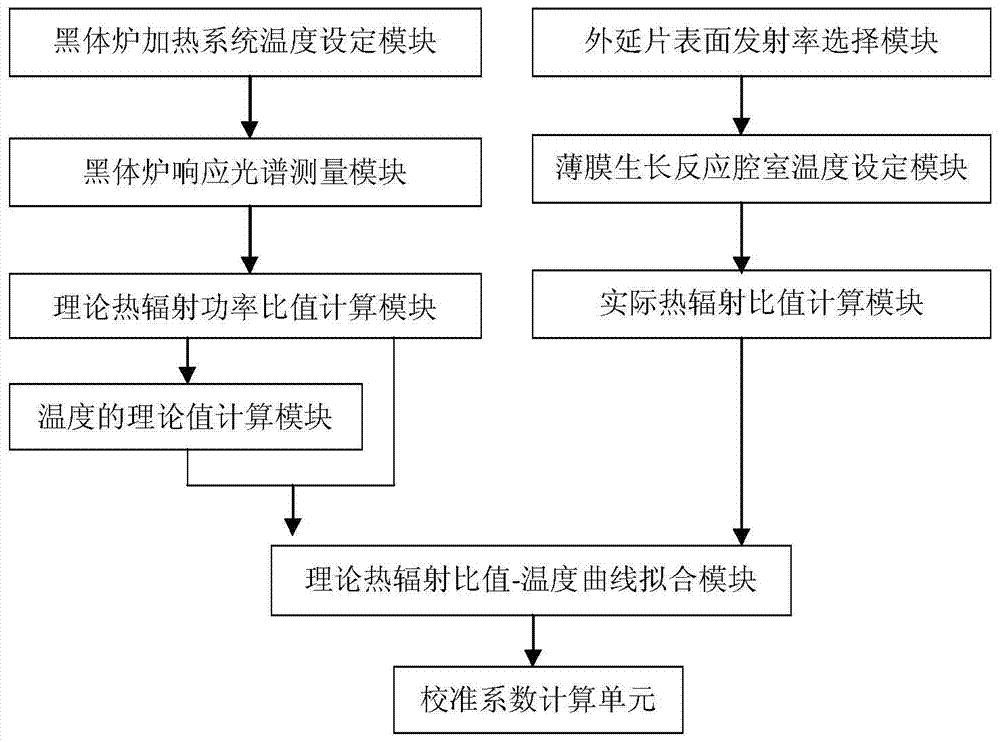

[0092] The self-calibration real-time temperature measuring device for thin film growth provided in the second embodiment of the present invention is a specific implementation of the self-calibrating real-time temperature measuring device for thin film growth provided in the first embodiment of the present invention. image 3 , including blackbody furnace heating system temperature setting module, blackbody furnace response spectrum measurement module, theoretical thermal radiation power ratio calculation module, theoretical value calculation module of temperature, theoretical thermal radiation ratio-temperature curve fitting module, epitaxial wafer surface emissivity selection Module, thin film growth reaction chamber reaction chamber temperature setting module, actual heat radiation ratio calculation module and calibration coefficient calculation unit.

[0093] The blackbody furnace response spectrum measurement module is used to measure the response spectrum of the blackbody...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com