Film growth self-calibration real-time temperature measurement device

A temperature measuring device and thin film growth technology, applied in measuring devices, optical radiation measurement, radiation pyrometry, etc., can solve the problems of temperature deviation, epitaxial wafer growth temperature measurement cannot be consistent and accurate, and achieve consistent measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] See attached figure 1 The self-calibrating real-time temperature measurement device for film growth provided by the present invention includes an actual thermal radiation ratio acquisition unit and a calibration coefficient calculation unit,

[0057] The actual thermal radiation ratio acquisition unit is used to acquire the actual thermal radiation ratio;

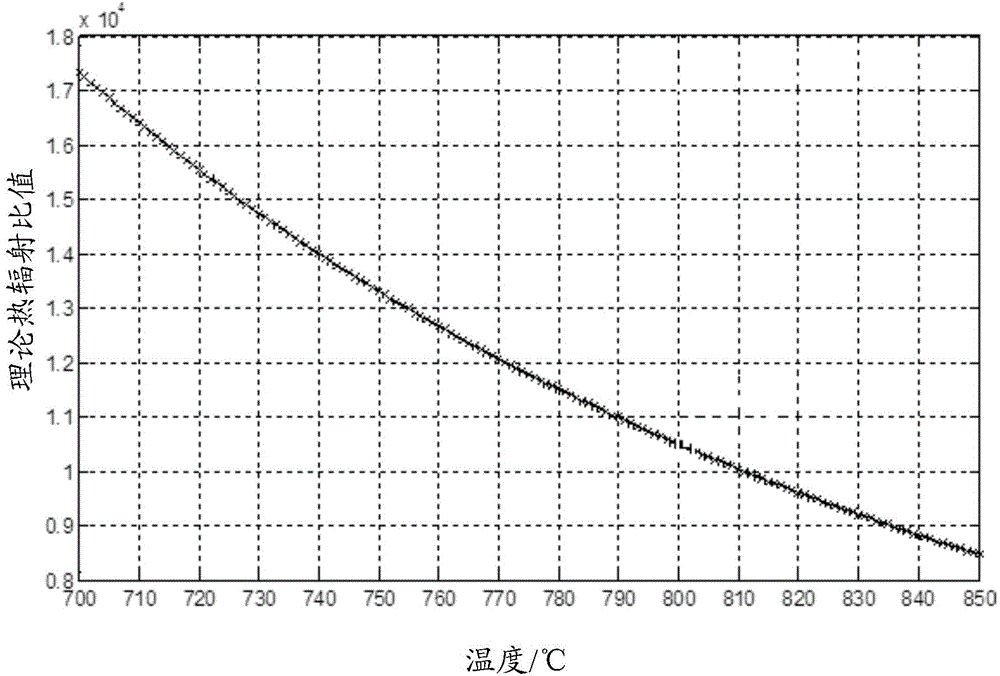

[0058] The calibration coefficient calculation unit is based on the actual heat radiation ratio, in the attached figure 2 Draw the point corresponding to the actual heat radiation ratio on the theoretical heat radiation ratio-temperature curve shown, and substitute the value of temperature T corresponding to the point into

[0059] L ( λ 1 , T ) = m 1 × ∫ λ 1 - ...

Embodiment 2

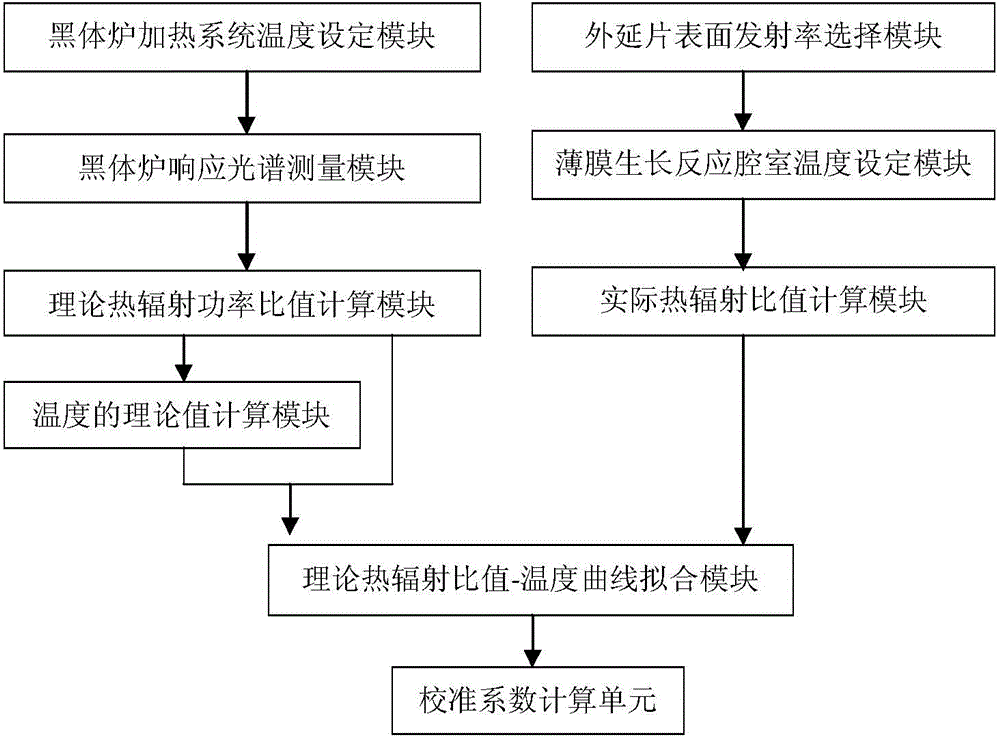

[0092] The self-calibrating real-time temperature measuring device for film growth provided in Embodiment 2 of the present invention is a specific implementation of the self-calibrating real-time temperature measuring device for film growth provided in Embodiment 1 of the present invention. Please refer to the attached image 3 , including the temperature setting module of the heating system of the blackbody furnace, the measurement module of the response spectrum of the blackbody furnace, the calculation module of the theoretical thermal radiation power ratio, the calculation module of the theoretical value of the temperature, the theoretical thermal radiation ratio-temperature curve fitting module, and the selection of the surface emissivity of the epitaxial wafer module, a film growth reaction chamber reaction chamber temperature setting module, an actual heat radiation ratio calculation module and a calibration coefficient calculation unit.

[0093] The blackbody furnace re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com