Preparation method for spherical cavity equipped polymer fiber and special microfluidic chip

A microfluidic chip and polymer technology, which is applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve problems such as difficult preparation of fiber materials, and achieve the effect of flexible polymerization methods and various types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

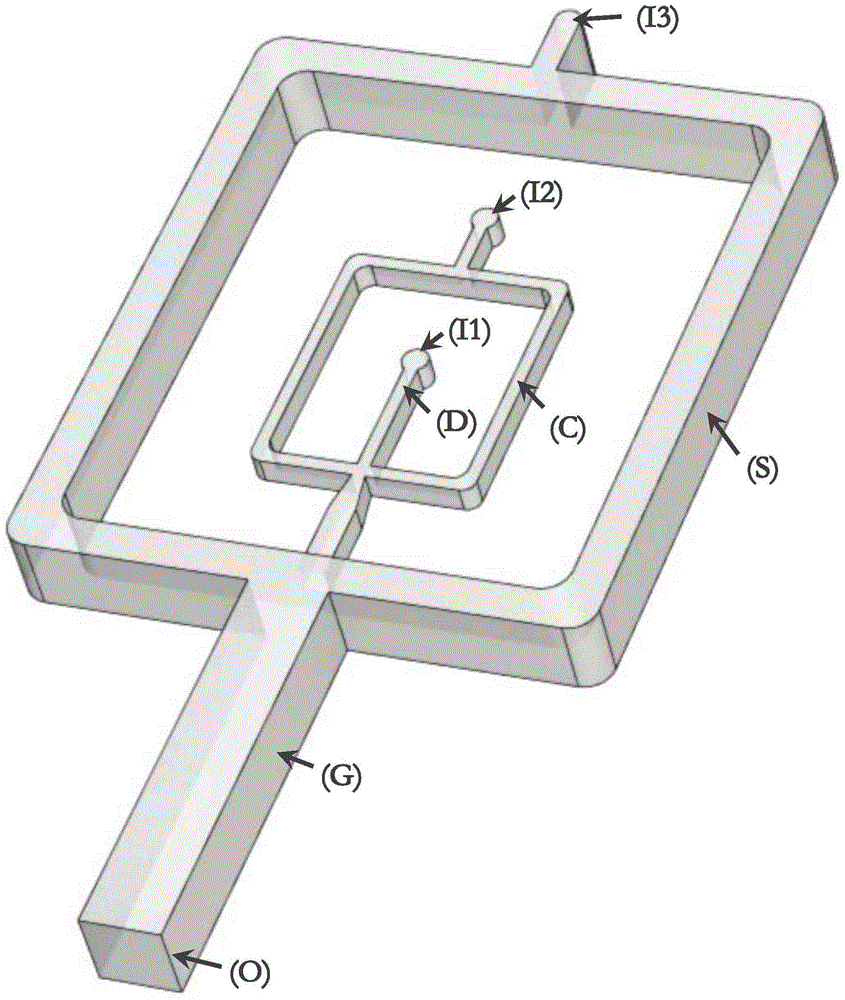

[0026] Embodiment 1: chip structure of the present invention

[0027] The microfluidic chip of the present invention is divided into two layers, the surfaces of the two layers of materials have channel structures, and the two channel structures are mirror-symmetrical, and the two-layer chip materials are sealed together when the two mirror-symmetrical channel structures overlap each other; wherein, The chip includes an inlet and a channel of a continuous phase solution, an inlet and a channel of a dispersed phase solution, an inlet and a channel of a sheath flow solution, an entrainment channel structural unit, a spout structural unit, a polymer fiber generation channel, and a product collection outlet.

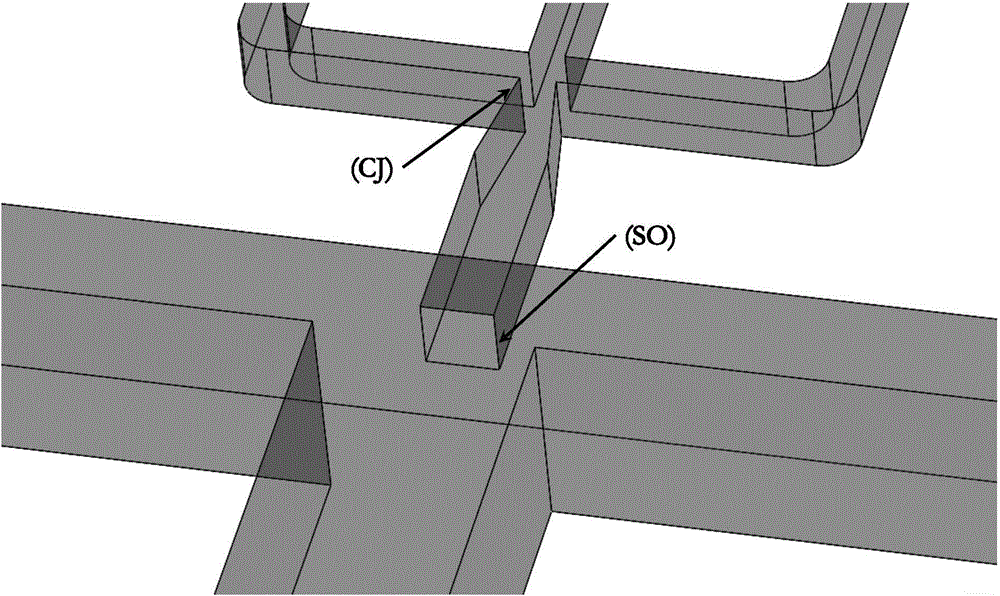

[0028] The entrainment channel structure is located upstream of the spout structure, and is the intersection of the continuous phase solution channel and the dispersed phase solution channel, and is in the shape of a cross.

[0029] The nozzle structural unit is located downs...

Embodiment 2

[0032] Formation of Monodisperse Droplets and Sheath Flow Patterns Using the Chip of the Invention

[0033] Using a syringe pump, inject non-polar solvent X (dispersed phase solution), polar solvent Y solution (continuous phase solution), and non-polar solvent Z (sheath flow solution) into the microfluidic chip through their respective inlets. The dispersed phase solution channel, the continuous phase solution channel and the sheath flow solution channel. Adjust the flow rate of each fluid to an appropriate range. It can be observed under a microscope that when the solvent X flows through the entrainment channel structural unit, it is dispersed into droplets by the solvent Y, and is continuously carried to the downstream nozzle structural unit by the solvent Y. When the solvent Y flows from the continuous phase solution channel through the nozzle structural unit into the polymer fiber to form a channel, it is wrapped by the solvent Z that also flows into this channel to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com