Aluminum member

A technology for components and vehicles, applied in coating, casting molding equipment, casting molds, etc., can solve the problems of high manufacturing cost, difference in cooling speed between thick-walled and thin-walled parts, and poor melt fluidity. Effects of improved fluidity and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

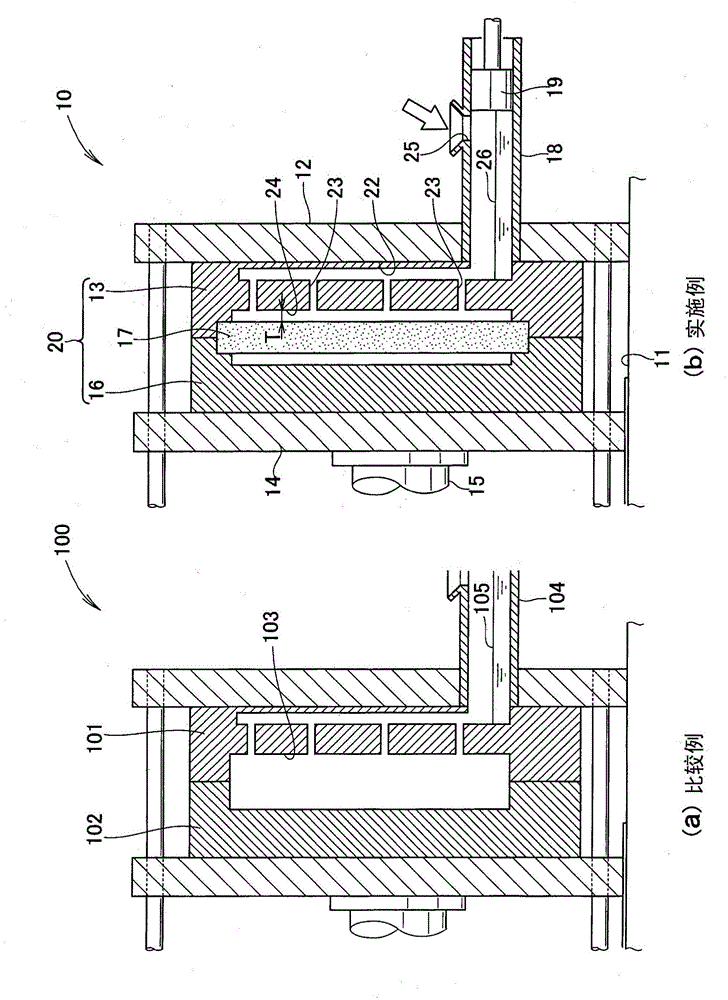

[0038] figure 1 In (a), the conventional die casting facility 100 will be described as a comparative example. That is, the molten metal 105 is injected from the sleeve 104 into the cavity 103 formed by the stationary mold 101 and the movable mold 102 . The cavity 103 is expanded so that a large thick-walled member can be obtained. It should be noted, figure 1 (a) is a schematic diagram. Although the cavity 103 is described as having a constant wall thickness, in a real member, the wall thickness difference becomes large. When the melt 105 with poor fluidity is injected, if the thickness difference is large, a difference in cooling rate occurs between the thick part and the thin part, and casting defects are likely to occur.

[0039] like figure 1 As shown in (b), the die casting equipment 10 according to the embodiment of the present invention includes, for example, a die base 11 , a fixed die plate 12 fixed to the die set 11 , a fixed die 13 mounted on the fixed die plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com