Al-Mg-Zn alloy

An al-mg-zn alloy technology, applied in the field of Al-Mg-Zn alloy, can solve the problems of quenching sensitivity, low strength, and large difference in the performance of the center of the material, etc., and achieve the effect of good hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

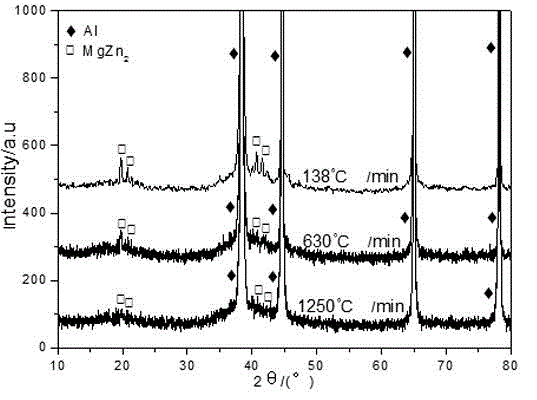

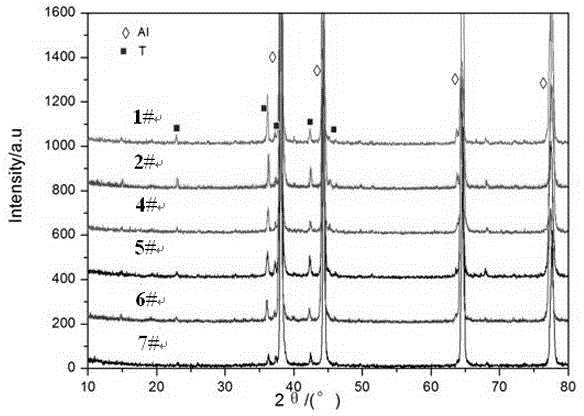

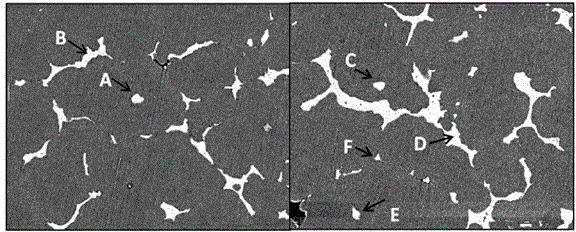

[0029] The present invention will be described in detail below in conjunction with 8 specific embodiments, but not limited to the illustrated embodiments.

[0030] In each embodiment, the weight percentage of alloy chemical composition is controlled as follows: Mg=6.0~10.0%; Zn=3.0~5.0%; Cu<2.0%; Mn<0.5%; Fe<0.3%; Si<0.3%; Addition of various elements < 0.5%, total compound addition < 0.8% (such as: adding Zr or Sc < 0.5% alone; or adding Zr and Sc in combination, wherein Zr < 0.5%, Sc < 0.5%, Zr+Sc < 0.8 %); inevitably there are other impurity elements, the single impurity element does not exceed 0.05%, the total amount of impurities does not exceed 0.2%, and the balance is Al; Zn / Mg=0.48~0.62.

[0031]In order to reflect the superiority of the material performance, the weight percentage of the alloy chemical composition in the embodiment is further controlled within the preferred range: Mg=7.0-9.0%; Zn=3.5-4.5%; Cu<1.5%; Mn<0.3%; Fe< 0.15%; Si<0.1%; Zr, Sc single element ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com