Halogen-free flame-retardant two-component polyurethane adhesive for railway vehicle and preparation method thereof

A two-component polyurethane and rail passenger car technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of body structure bonding and other problems, and achieve good flame retardant effect, good toughness, and adhesion The effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

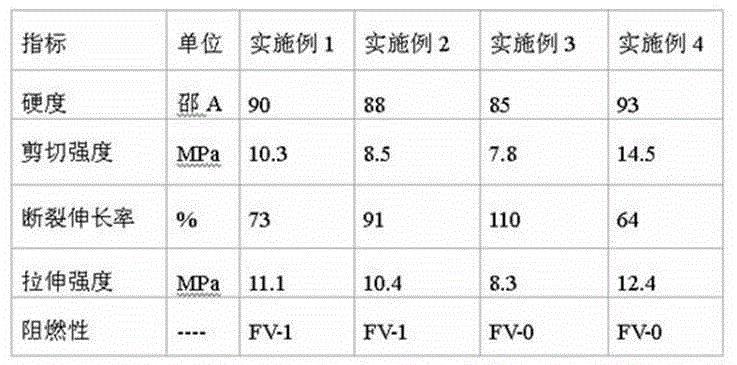

Embodiment 1

[0020] Add castor oil polyol 13.2% Wt, polyester polyol (hydroxyl value 167mgKOH / g, molecular weight 1000) 12.2%Wt, bisphenol A polyether polyol (hydroxyl value 270mgKOH / g, molecular weight 450) 5.4% Wt, flame retardant plasticizer dimethyl phosphate 11.4% Wt, heated to 120 ° C, and dehydrated under vacuum for 2 hours, then cooled to 60 ° C, added to the planetary mixer, Then add 57.0% Wt of aluminum hydroxide, 0.58% Wt of epoxy-terminated silane coupling agent, and 0.25% Wt of organometallic catalyst, stir for 2 hours in a vacuum state, and discharge, which is A component. Component B is liquefied polymethylene polyphenyl polyisocyanate. It can be used after being fully mixed according to A?B=6?1 (mass ratio).

Embodiment 2

[0022] Add castor oil polyol 19.4% Wt, polyester polyol (hydroxyl value 120mgKOH / g, molecular weight 1540) 21.5%Wt, bisphenol A polyether polyol (hydroxyl value 200mgKOH / g, molecular weight 658) into the three-necked flask ) 6.5% Wt, flame retardant plasticizer ethyl diethyl phosphate 8.6% Wt, heated to 120 ° C, and dehydrated under vacuum for 2 hours, then cooled to 60 ° C, added to the planetary mixer, and then Add 21.5% Wt of magnesium hydroxide, 21.5% Wt of aluminum hydroxide, 0.7% Wt of epoxy-terminated silane coupling agent, 0.3% Wt of organometallic catalyst, etc., stir for 2 hours in a vacuum state, and discharge the material, which is component A . Component B is a mixture of liquefied diphenylmethane diisocyanate 50%wt and diphenylmethane diisocyanate 50%wt. It can be used after being fully mixed according to A?B=6?1 (mass ratio).

Embodiment 3

[0024] Add castor oil polyol 20.8% Wt, polyester polyol (hydroxyl value 76mgKOH / g, molecular weight 2000) 10.4%Wt, bisphenol A polyether polyol (hydroxyl value 270mgKOH / g, molecular weight 450) 10.4% Wt, flame retardant plasticizer triisopropylphenyl phosphate 12.7% Wt, heated to 120°C, dehydrated under vacuum for 2 hours, then cooled to 60°C, and added to the planetary stirring mixer , then add 44.8% Wt of magnesium hydroxide, 0.9% Wt of epoxy-terminated silane coupling agent, 0.1% Wt of organometallic catalyst, stir for 2 hours in a vacuum state, and discharge the material, which is A component. Component B is a mixture of 50% wt of polymethylene polyphenyl polyisocyanate and 50% wt of liquefied diphenylmethane diisocyanate. It can be used after being fully mixed according to A?B=6?1 (mass ratio).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com