Preparation method of adhesive for wooded furniture

A wood furniture and adhesive technology, applied in the direction of adhesives, adhesive types, non-polymer adhesive additives, etc., can solve the problems of unreachable and high formaldehyde content, and achieve scientific steps, simple preparation steps, and oxidation prevention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

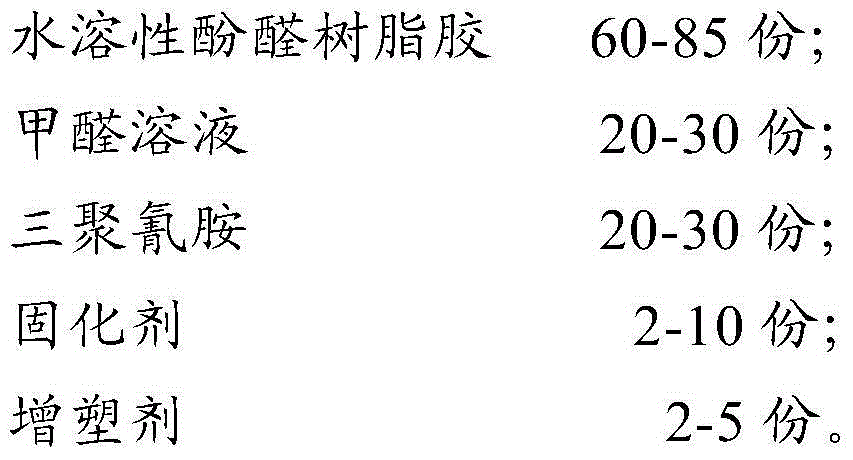

[0015] This embodiment discloses a preparation method of an adhesive for wooden furniture, which includes the following steps: adding the formula of the adhesive for wooden furniture into a reaction kettle, vacuuming the reaction kettle, continuously stirring and raising the temperature to 70°C, and after it is completely dissolved, Cool to room temperature. Cooling adopts water cooling or air cooling. The formula of described wooden furniture adhesive comprises the following components in weight ratio:

[0016] The formula of described wooden furniture adhesive comprises the following components in weight ratio:

[0017]

Embodiment 2

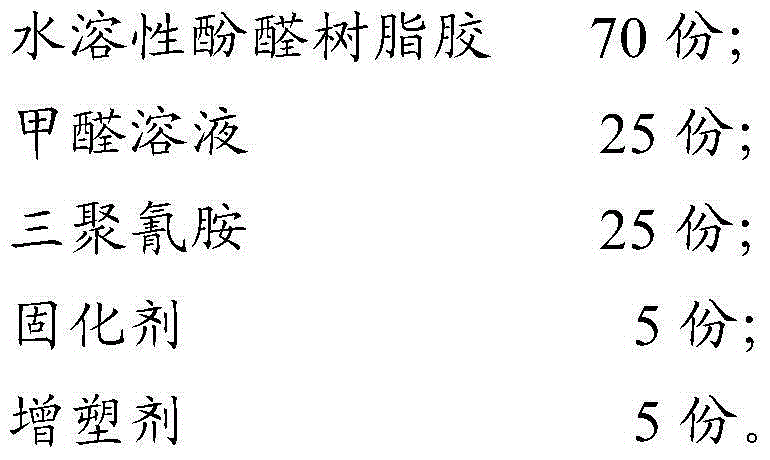

[0019] This embodiment discloses a preparation method of an adhesive for wooden furniture, which includes the following steps: adding the formula of the adhesive for wooden furniture into a reaction kettle, vacuuming the reaction kettle, stirring continuously and raising the temperature to 80°C, and after it is completely dissolved, Cool to room temperature. Cooling adopts water cooling or air cooling.

[0020] The formula of described wooden furniture adhesive comprises the following components in weight ratio:

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com