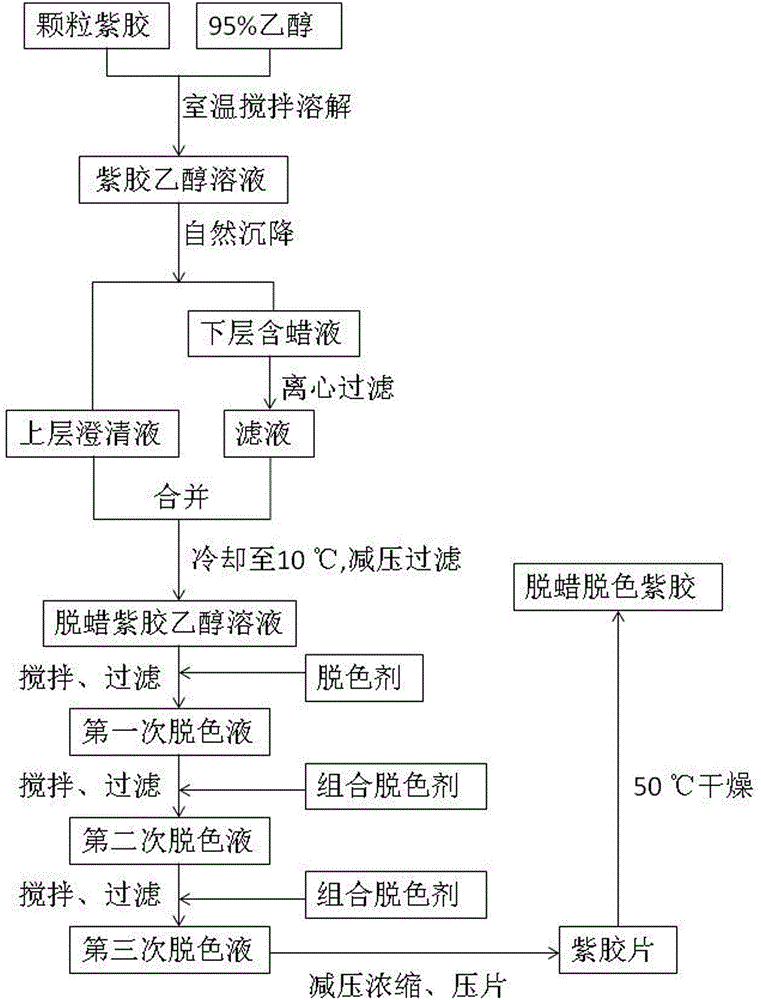

Preparation method of dewaxed and decolorized shellac

A kind of shellac and decolorization technology, applied in the field of preparation of dewaxed and decolorized shellac, can solve the problems of not meeting market requirements, poor decolorization effect, etc., and achieve the effects of reducing filtration time, reducing energy consumption, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 100g granular shellac (color is purple, color index ≤ 18) mixed with 300g 95% ethanol, then fully stir at room temperature to form a shellac ethanol solution with a mass ratio of 1:3, put the shellac ethanol solution at room temperature Stand still for 24 hours to fully precipitate the shellac wax and impurities, separate the upper clarified liquid (about 2 / 3 of the total volume of the solution), and centrifugal filter the lower layer (about 1 / 3 of the total volume of the solution). The clear liquid obtained was combined with the supernatant liquid, and the combined shellac ethanol solution was cooled to 10° C., filtered under reduced pressure to obtain dewaxed shellac ethanol solution; 20 g of activated carbon (commercially available industrial product) was added to the shellac ethanol solution , stirring at 70°C for 45 minutes for decolorization, after the decolorization is completed, filter under reduced pressure while hot to obtain the first decolorization g...

Embodiment 2

[0027]Take 100g granular shellac (color is purple, color index ≤ 18) mixed with 400g 95% ethanol, and then fully stirred at room temperature to form a shellac ethanol solution with a mass ratio of 1:4, and the shellac ethanol solution at room temperature Stand still for 24 hours to fully precipitate the shellac wax and impurities, separate the upper clarified liquid (about 2 / 3 of the total volume of the solution), and centrifugal filter the lower layer (about 1 / 3 of the total volume of the solution). The clear liquid obtained was combined with the supernatant liquid, and the combined shellac ethanol solution was cooled to 10° C., filtered under reduced pressure to obtain dewaxed shellac ethanol solution; 20 g of activated carbon (commercially available industrial product) was added to the shellac ethanol solution , decolorized at 70°C for 45 minutes with constant temperature stirring, and filtered under reduced pressure while hot to obtain the first decolorized glue; add 10g of...

Embodiment 3

[0029] Take 100g granular shellac (color is purple, color index ≤ 18) mixed with 300g 95% ethanol, then fully stir at room temperature to form a shellac ethanol solution with a mass ratio of 1:3, put the shellac ethanol solution at room temperature Stand still for 24 hours to fully precipitate the shellac wax and impurities, separate the upper clarified liquid (about 2 / 3 of the total volume of the solution), and centrifugal filter the lower layer (about 1 / 3 of the total volume of the solution). The clear liquid obtained is combined with the supernatant liquid, and the combined shellac ethanol solution is cooled to 10° C., filtered under reduced pressure to obtain dewaxed shellac ethanol solution; add 15 g of activated carbon (commercially available industrial product) to the shellac ethanol solution , decolorized at 70°C for 45 minutes with constant temperature stirring, and filtered under reduced pressure while hot to obtain the first decolorized glue; add 7.5g activated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com