Fireproof coating solution for expanded polystyrene thermal insulation material and coating process of coating solution

A foamed polystyrene, thermal insulation material technology, applied in fire-resistant coatings, coatings, epoxy resin coatings, etc., can solve the problems of increased bulk density, decreased thermal insulation performance, inability to achieve large-scale industrial production, etc., and achieves inhibition of thermal decomposition. , Improve the effect of flame retardant and fire protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

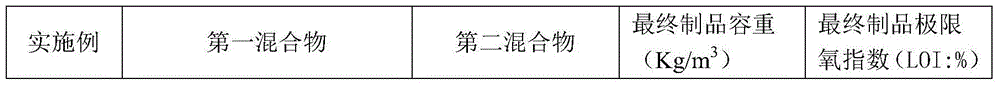

Embodiment 1

[0057] Make the first mixture: take 60.00g of dimethyl methylphosphonate (DMMP), add 30.00g of resorcinol bis[bis(2,6-dimethylphenyl)phosphate] (PX200), and stir at room temperature until the solid flame retardant is completely dissolved to obtain the first mixture.

[0058] Take 100.00g of pre-made EPS beads (loose density 15Kg / m 3 ), add 30.00g of the first mixture, stir and coat evenly; then add 70.00g of the second mixture, stir and coat evenly again, and dry at 50-55°C at low temperature to obtain flame-retardant thermosetting coated EPS beads.

[0059] After the bead is formed according to the conventional scale pressing process, the bulk density is 30Kg / m 3 The EPS board has a limiting oxygen index (LOI value) of 28.5.

Embodiment 2

[0061] Make the first mixture: Take 60.00g of diethyl ethylphosphonate (DEEP), add 30.00g of resorcinol bis[bis(2,6-dimethylphenyl)phosphate] (PX200), and stir at room temperature until the solid flame retardant is completely dissolved to obtain the first mixture.

[0062] Take 100.00g of pre-made EPS beads (loose density 15Kg / m 3 ), add 30.00g of the first mixture, stir and coat evenly; then add 70.00g of the second mixture, stir and coat evenly again, and dry at 50-55°C at low temperature to obtain flame-retardant thermosetting coated EPS beads.

[0063] After the bead is formed according to the conventional scale pressing process, the bulk density is 30Kg / m 3 The EPS board has a limiting oxygen index (LOI value) of 28.2.

Embodiment 3

[0065] Make the first mixture: Take 60.00g of dimethyl propyl phosphonate (DMPP), add 30.00g of resorcinol bis[bis(2,6-dimethylphenyl)phosphate] (PX200), and stir at room temperature until the solid flame retardant is completely dissolved to obtain the first mixture.

[0066] Take 100.00g of pre-made EPS beads (loose density 15Kg / m 3 ), add 30.00g of the first mixture, stir and coat evenly; then add 70.00g of the second coating mixture, stir and coat evenly again, and dry at 50-55°C at low temperature to obtain flame-retardant thermosetting coated EPS beads.

[0067] After the bead is formed according to the conventional scale pressing process, the bulk density is 30Kg / m 3 The EPS board has a limiting oxygen index (LOI value) of 29.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com