Technique for processing millet with remained germ

A processing technology, the technology of leaving germ rice, applied in the direction of grain germ removal, solid separation, grain treatment, etc., can solve the problems of not meeting the requirements of millet processing, loss of embryo nutrition, and excessive crude fiber, etc., to achieve scientific and reasonable process design, Implement the effect of mature technology and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

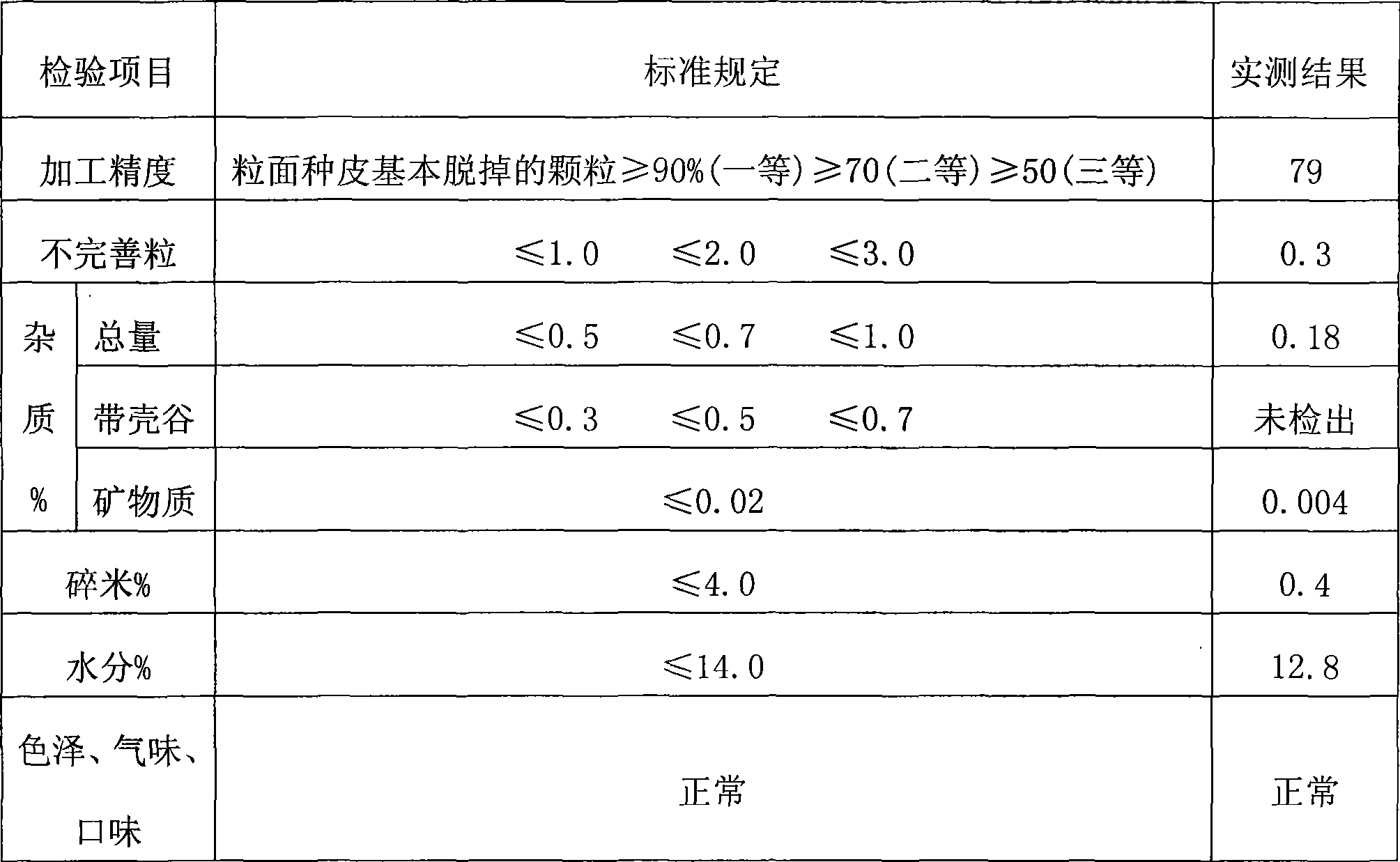

[0022] 1. Selection of raw grains: Use the 150T millet production line per day, and choose excellent millet from Jianping Zhuluke in Liaoning Province that meets the second-class standard of GB8232-1987. For example, Shanxi red millet, golden seedling millet and so on. Red millet and golden seedling millet are processed at a ratio of 3:2 to 30T.

[0023] 2. Millet sorting: first use the primary cleaning sieve to clean out the large impurities; use the vibrating screen to clean out the small and medium impurities; use the suction separator to clean up the light impurities; use the stone remover to clean up the side stones; use the magnetic separator to clean up the metal The two-seater rubber roller huller is used for secondary hulling, so that the hulling rate and rice germ integrity rate both reach ≥ 97%; brown rice is screened out through paddy separation.

[0024] Selected brown rice indicators: brown rice moisture is about 13.0Wt%, low imperfect grains, especially less th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com