Device for centrifugal recovery of saline water after concentration and crystallization

A technology for concentrating crystallization and brine, applied in the direction of alkali metal chloride, energy input, etc., can solve the problems of easy clogging of the crystallization tank, difficult separation and removal, small heat exchange area, etc., to achieve perfect functions, strong practicability and broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

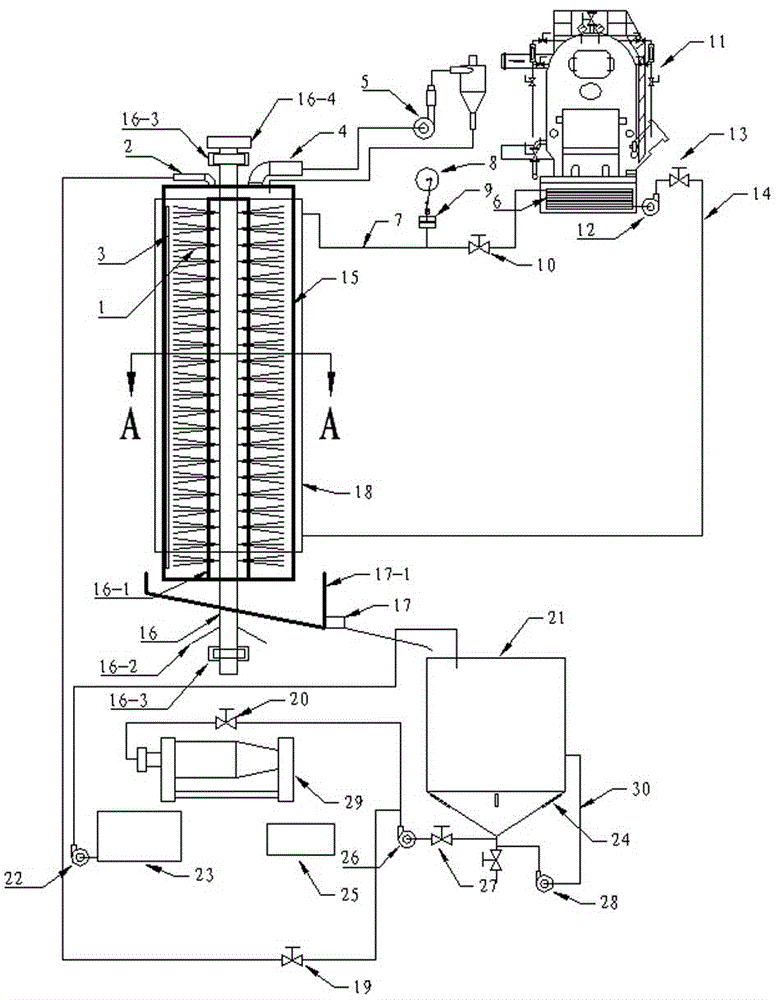

[0030] Now in conjunction with accompanying drawing, the present invention is described in further detail.

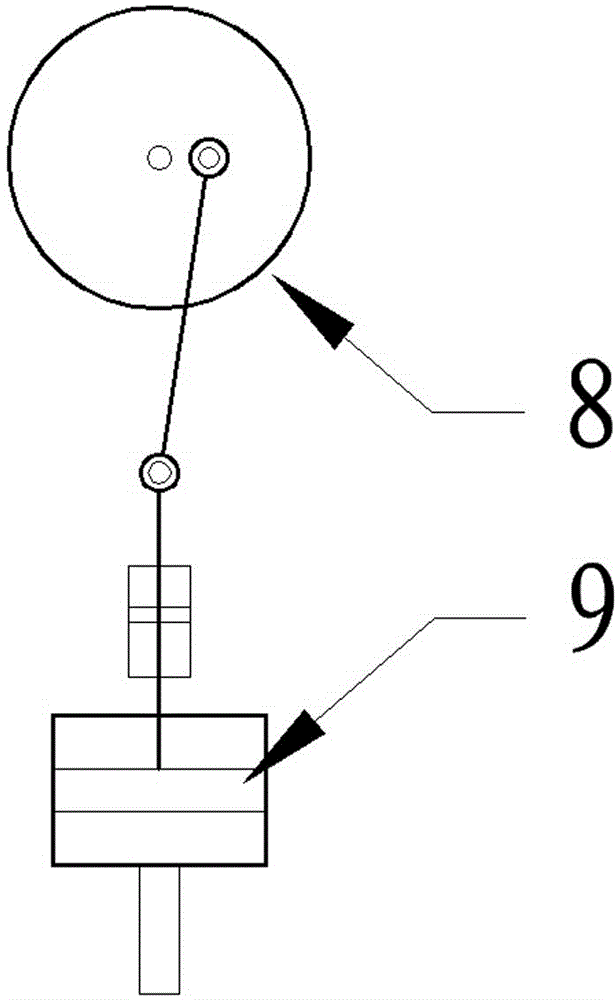

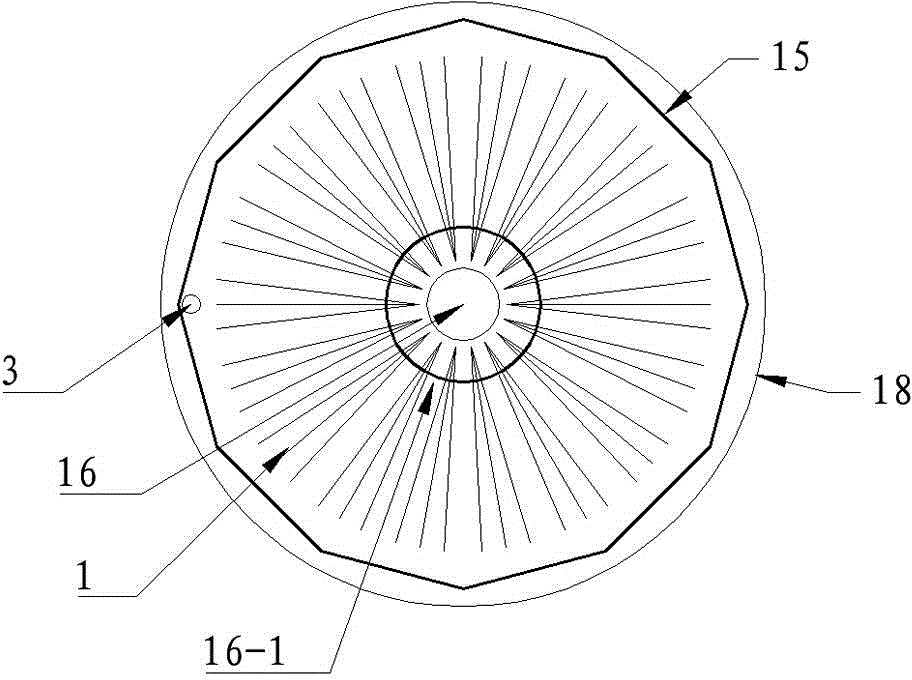

[0031] like figure 1 , figure 2 and image 3 The device for concentrating and crystallizing brine shown in the figure includes a concentration heat exchange tank and a crystallization tank 21. The concentration heat exchange tank is a jacketed elongated cylindrical structure composed of an inner cylinder 15 and an outer cylinder 18 and is vertically arranged. The inner cylinder 15 The section is a regular polygon; the rotating shaft 16 passes through the inner cylinder longitudinally, and the bristle drum 16-1 on the rotating shaft is implanted into the fiber brush bundle 1; Connect back to the inner tube 15 of the concentration heat exchange tank to form an evaporation circuit; the jacket of the concentration heat exchange tank and the return pipe 7, the heat exchange tube 6 of the waste water pool of the boiler 11, the circulating water pump 12 and the water inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com