Braking system of electric locomotive based on high-power inverter

A technology for electric locomotives and braking systems, applied in electric braking systems, electric vehicles, electric vehicle charging technology, etc., can solve problems such as low energy utilization, raising grid voltage, permanent magnet demagnetization, and braking failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

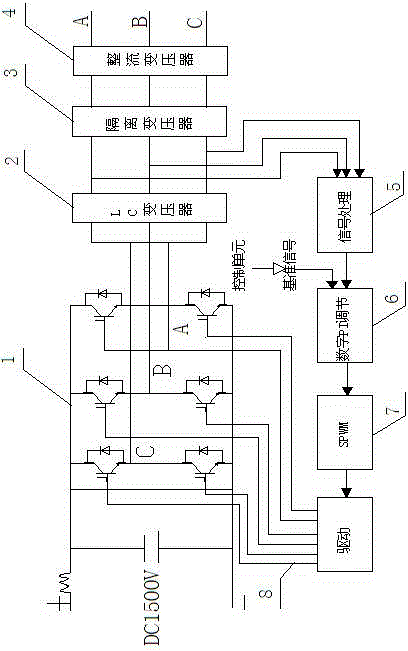

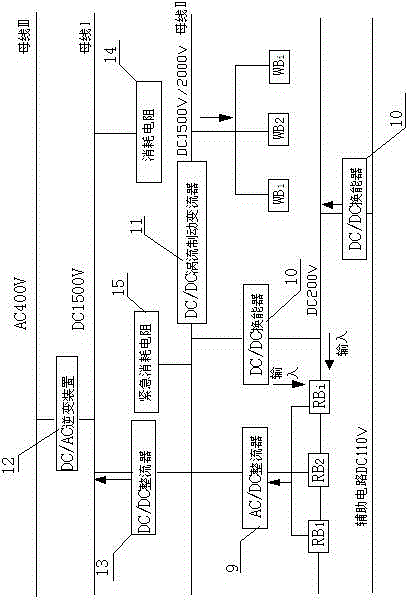

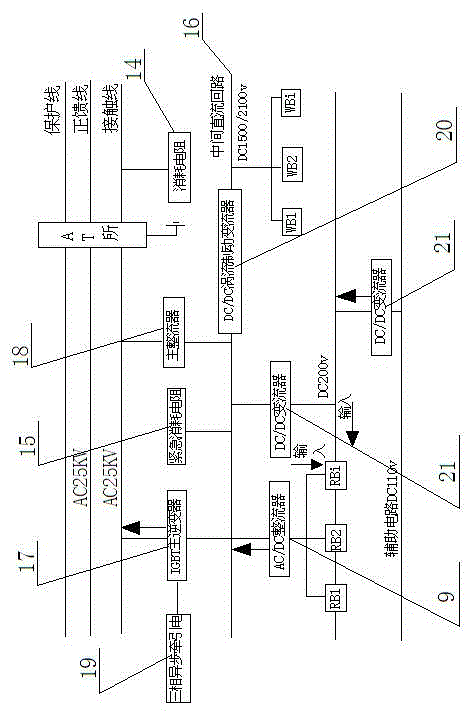

[0057] Combine below Figure 1 to Figure 3 The given examples further illustrate the present invention, but the examples do not constitute any limitation to the present invention.

[0058] An electric locomotive braking system, in which the regenerative energy inverter feedback system uses the principle of motor conversion to consume mechanical energy, inverts the DC power during vehicle braking into AC power, and feeds it back to the AC grid for grid-connected utilization.

[0059] The eddy current brake system is used to convert the kinetic energy of the train into eddy current in the electromagnetic induction body through electromagnetic induction, and dissipate it to the surroundings in the form of heat to achieve the purpose of braking.

[0060] The vehicle control unit is used for the power distribution of the eddy current braking system of the whole train, the distribution of the regenerative braking of the whole train and the coordination between the two.

[0061] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com