Gas dust collector

A dust collector and gas technology, applied in the field of dust removal equipment, can solve the problems of unsatisfactory fine dust collection effect, high filter bag replacement cost, high user operation and maintenance cost, and achieves reduction of secondary dust, high practicability, dust removal and purification. Efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

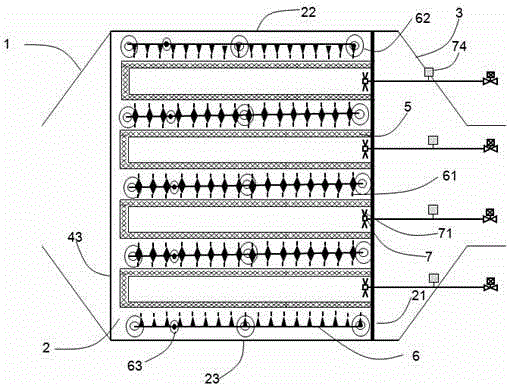

[0039] combine Figure 1 to Figure 3 As shown, the clean air chamber 3 is located above the dust removal chamber 2. It consists of a dust removal chamber 2, a clean air chamber 4, a dust storage box 5, a discharge electrode plate 6, a soot blower 7 and an ash bucket 8. The dust removal chamber 2 is a chamber with a rectangular structure, the front end is connected to the air inlet 1, the bottom support plate 24 is connected to the ash hopper 8, the rear partition 21 is arranged at the rear, the left wallboard 22 is arranged on the left side, and the right side The right side wallboard 23 is set; the clean air chamber 4 is located at the top of the dust removal chamber 2, the bottom of the clean air chamber 4 is connected with the dust removal chamber 2 through the lower partition 41 and forms an independent chamber, and the tail is connected with the air outlet 3. Each dust removal chamber is evenly distributed and fixedly installed with more than 3 dust removal units; The d...

Embodiment 2

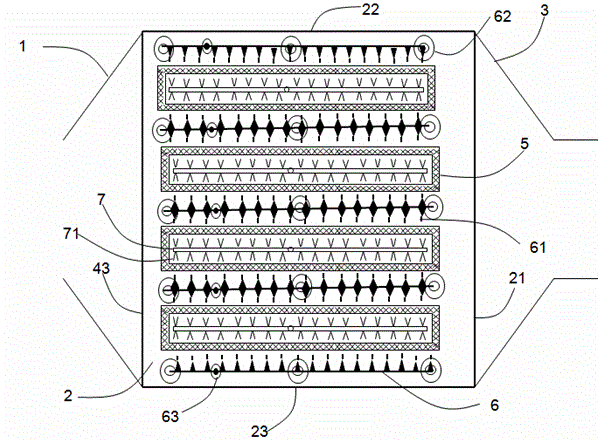

[0044] combine Figure 4 to Figure 6 As shown, its structure is similar to that in Example 1, and includes an air inlet 1, a dust removal chamber 2, an air outlet 3, a clean air chamber 4, a dust accumulation box 5, a discharge electrode plate 6, a soot blower 7 and an ash The bucket 8 is formed; the clean air chamber is still arranged on the top of the dust removal chamber 2, and its specific structure will not be repeated here. The difference is that the dust storage box in the dust removal chamber 2 is connected with the left and right side wall panels of the dust removal chamber. Of course, it can also be connected with the front and rear side wall panels. One side, and be located at the bottom of clean air chamber 4 air outlets. At this time, the sootblower in the dust box moves forward and backward to blow soot.

Embodiment 3

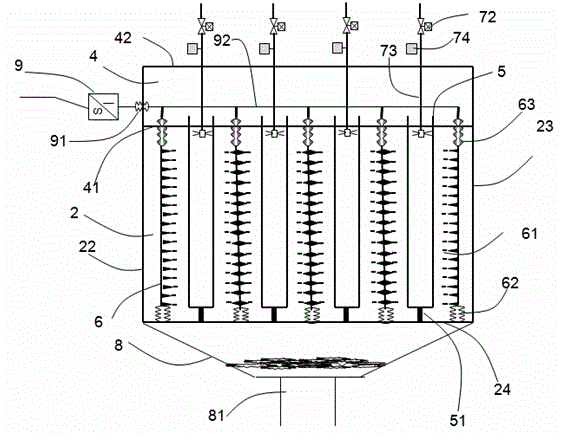

[0046] As a third embodiment, the clean air chamber 4 is arranged adjacent to the side of the dust removal chamber in this embodiment, and the air inlet and outlet of the airflow in this solution are linear. Similarly, the gas dust collector is composed of an air inlet 1, a dust removal chamber 2, an air outlet 3, a dust accumulation box 5, a discharge electrode plate 6, a soot blower 7 and an ash hopper 8; the dust removal unit is composed of a dust accumulation box 5, a discharge electrode plate 6. The dust box support beam 51 and the discharge electrode support insulator 62 are composed; the dust box 5 is hollow and rectangular, and the front end, left and right sides, upper part, and lower part are closed by a metal frame and a high-porosity porous material installed in the frame. The opening is also connected with the rear partition 21 of the dust removal chamber, and the size and shape of the rear partition 21 opening of the dust removal chamber are consistent with the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com