Novel tower plate-structure rectifying tower for maleic anhydride refining

The technology of rectifying tower and tray is applied in the field of rectifying tower, which can solve the problems of low production capacity, large steam consumption, decreased acid feeding capacity, etc., so as to achieve the effects of improving the refining capacity of equipment, saving steam consumption and increasing production profits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

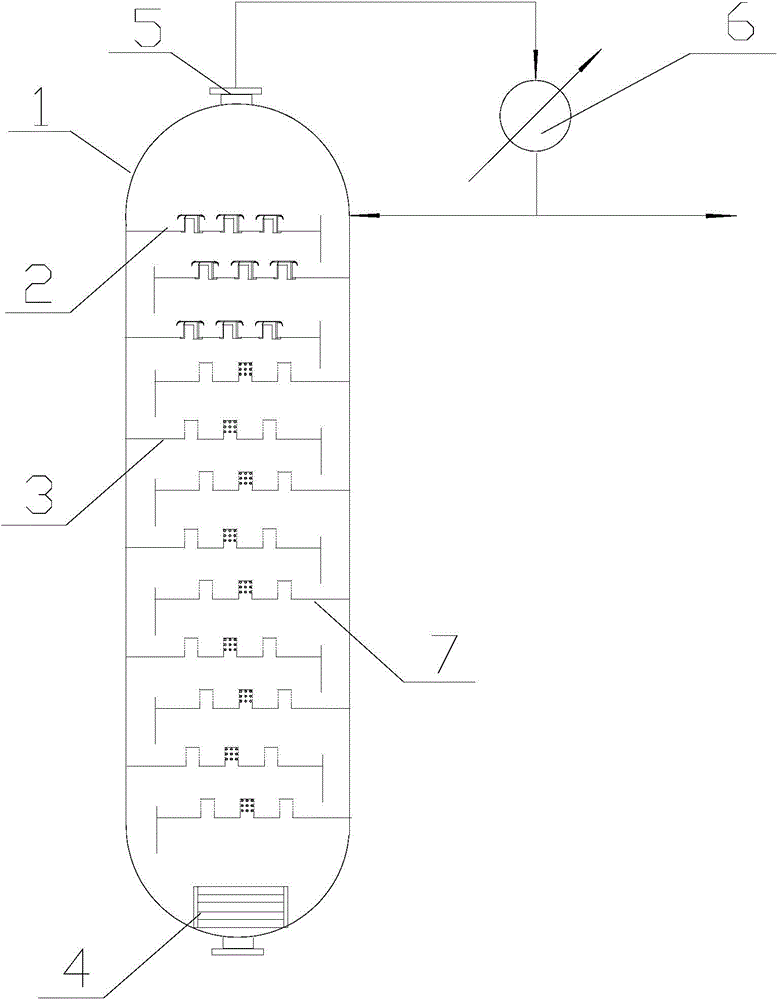

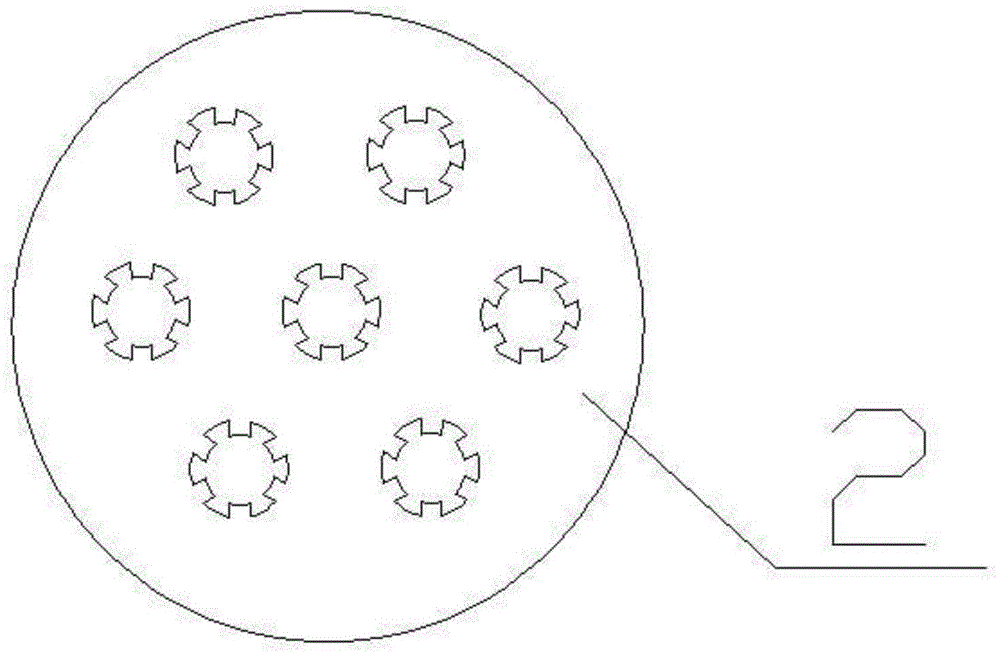

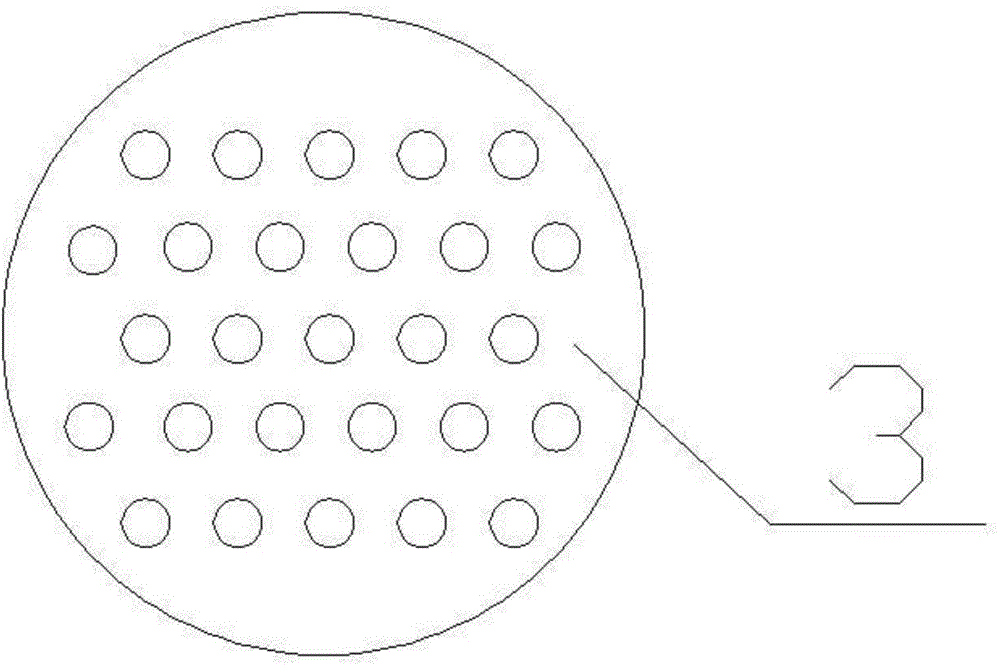

[0016] Such as Figure 1-5 As shown, a rectification tower with a novel tray structure for the purification of maleic anhydride includes a tower body 1, a valve tray group and a sieve tray group, and is characterized in that: the bottom of the tower body 1 is provided with a tower Kettle heater 4, the top of the tower body 1 is provided with a tower top outlet 5, and the tower top outlet 5 is fixedly connected with the condenser 6 through pipelines, and the valve tray group and the sieve tray group are arranged on the tower body 1 Between the inner walls on both sides, it is vertically arranged and fixedly connected with the inner wall of the tower body 1, and the valve tray group is arranged above the sieve tray group, and the valve tray group is composed of several valve tower trays 2 , the sieve tray group is composed of sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com