Online automatic sugar liquor brix measurement and control system

A technology of sugar liquid hammer, measurement and control system, which is applied in control/regulation system, non-electric variable control, measurement device and other directions, can solve the problems of difficult process operation, reduced precision, and difficult to clean the detection results, so as to ensure the quality of white sugar, Ensure efficient and thorough effect of control operation and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

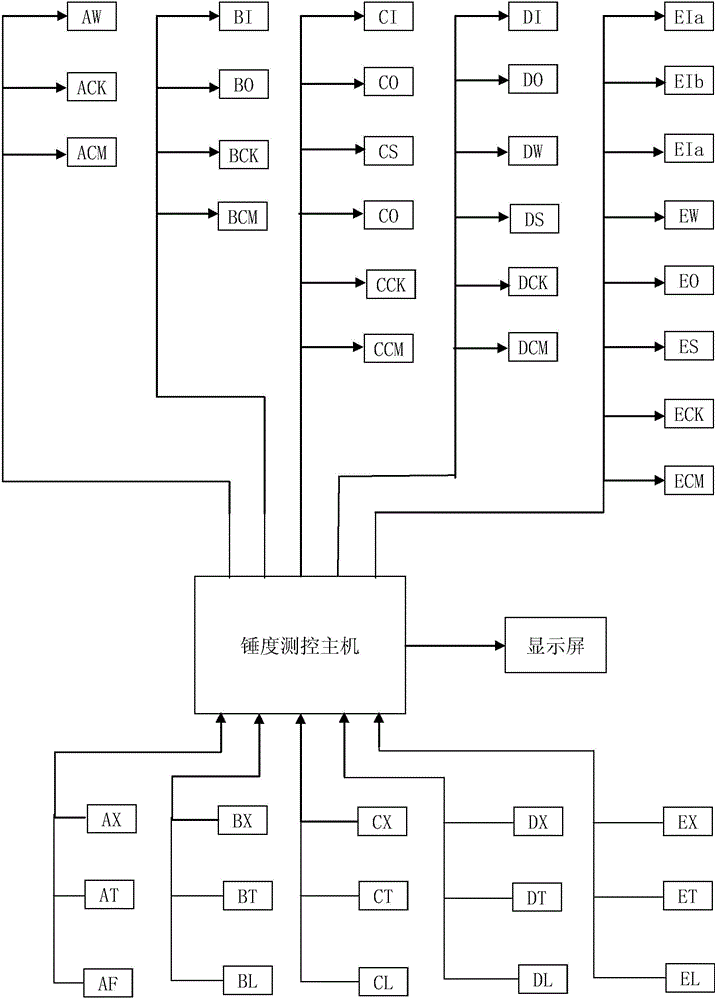

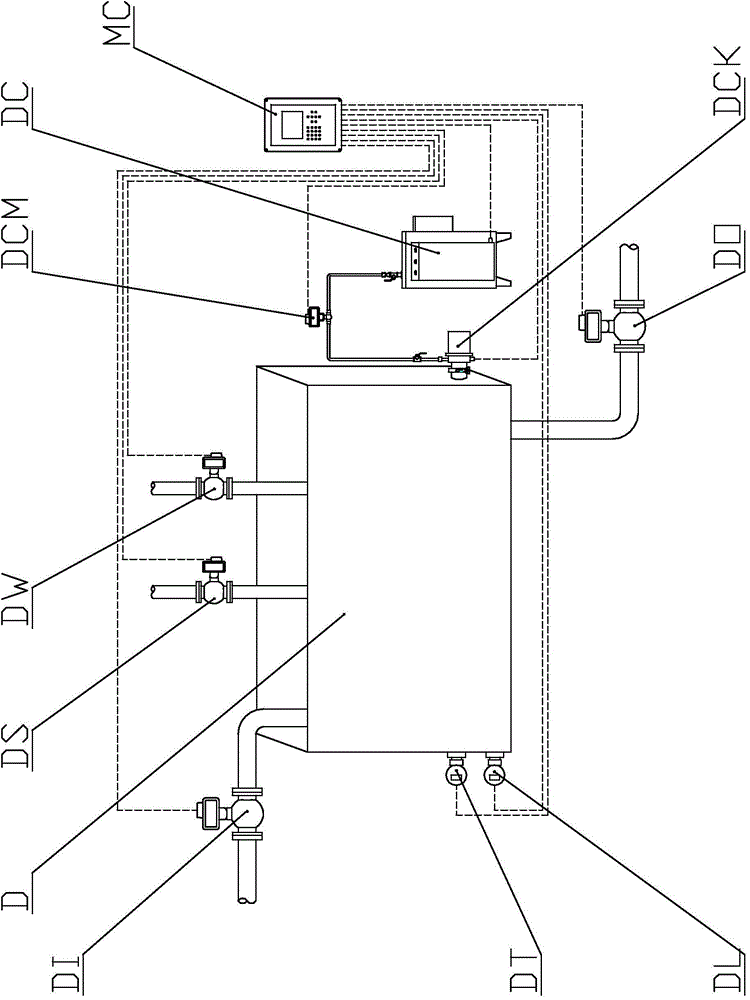

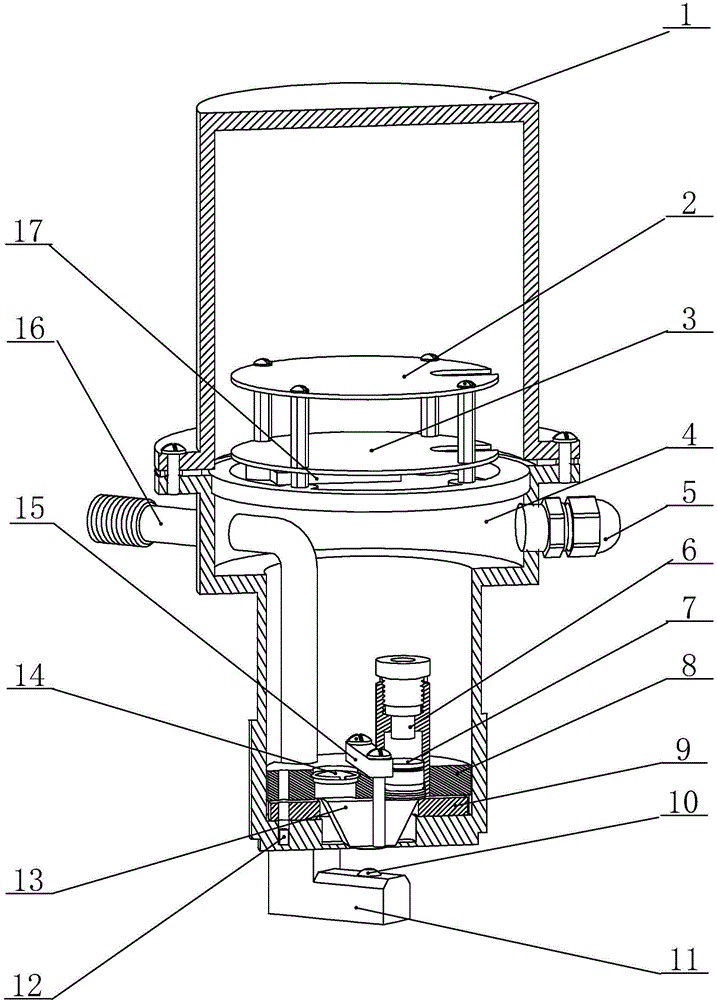

[0031] The embodiment of the on-line automatic measurement and control system for sugar solution hammer is applied to sugar factories with sugar cane as raw material. tank E.

[0032] Squeezed juice dilution tank A is connected with 1 feed pipe connected to cane juice, 1 water pipe as diluent pipe and 1 cane juice outlet pipe as discharge pipe; solenoid valve AW is installed on the dilute liquid pipe, and the discharge pipe Install the flowmeter AF on it, and install the hammer detector AX and the matching high-pressure hot steam generator AC. The high-pressure hot steam generator AC has an electromagnetic switch ACK, and the steam pipeline has a cleaning control electromagnetic valve ACM; a temperature sensor AT is also installed in the tank ;

[0033] One-effect evaporator B is connected with 1 feed pipe, 1 steam pipe, 1 juice steam outlet pipe and 1 discharge pipe; the feed pipe is equipped with solenoid valve BI, and the discharge pipe is equipped with solenoid valve BO; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com