Fully automatic automobile motor delivery test measurement and control system

A factory test, measurement and control system technology, applied in the field of motor manufacturing, can solve the problems of low production efficiency and great influence of test results, and achieve the effect of improving production efficiency, improving accuracy and repeatability, and reducing the influence of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

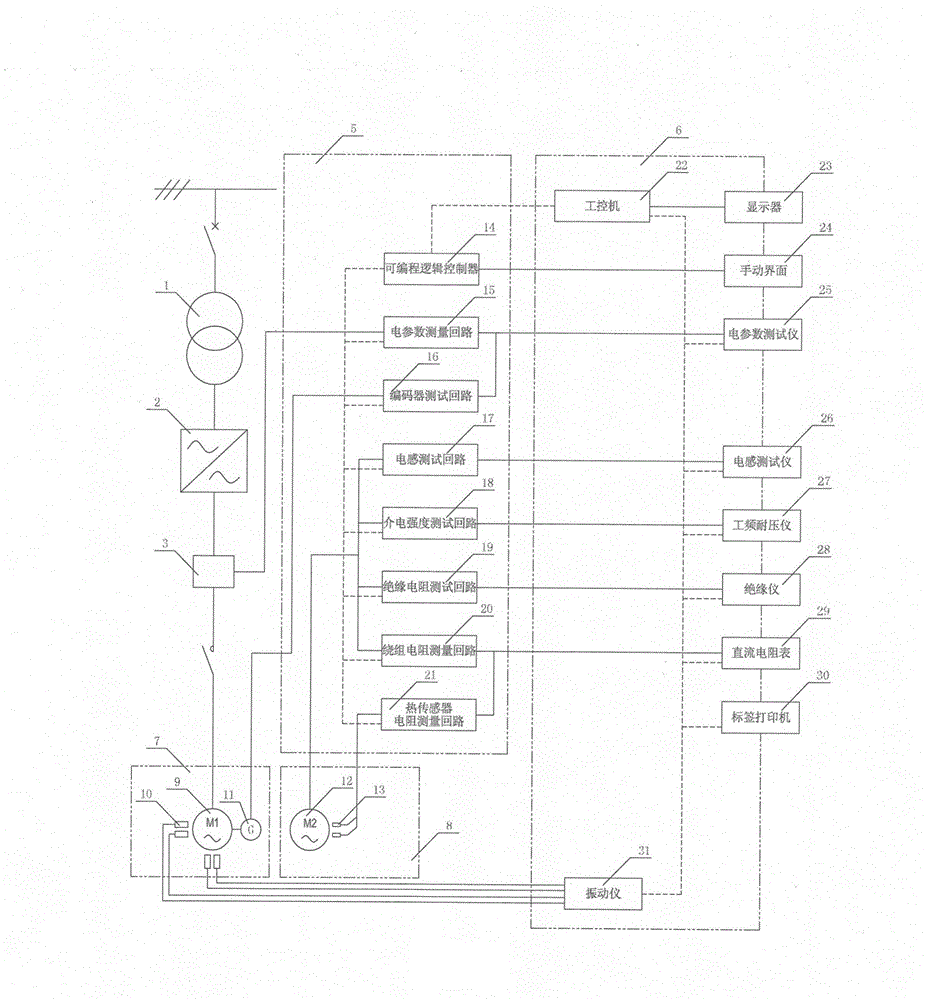

[0034] to combine figure 1 , A kind of automatic automobile motor ex-factory test measurement and control system provided by the present invention includes: transformer 1, frequency conversion power supply 2, electric parameter measurement system 3, control system 5, measuring instrument 6, dynamic test station 7, static test station 8.

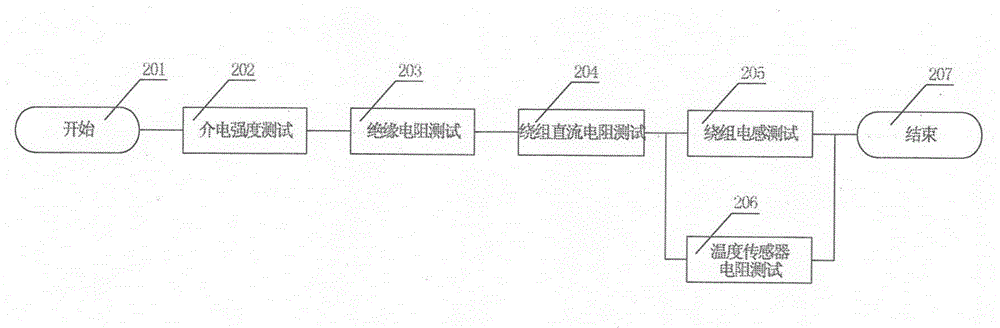

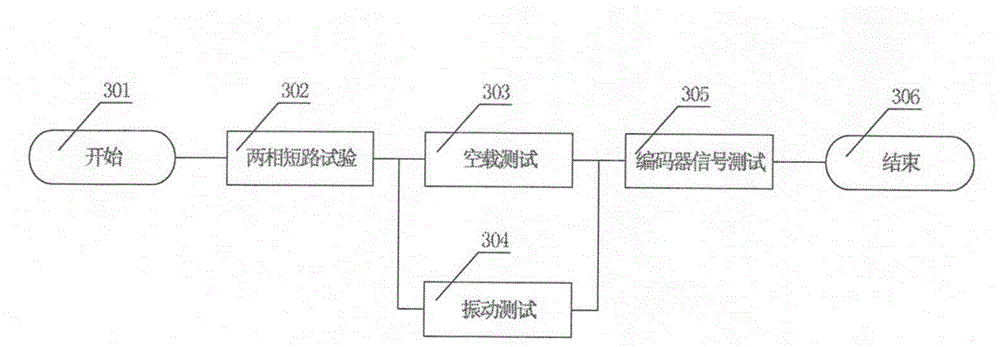

[0035] Wherein, static test station 8 comprises tested motor 2 12 and thermal sensor 13 of tested motor 2 12, tested motor 2 12 and inductance test loop 17, dielectric strength test loop 18, insulation resistance test loop 19, winding resistance The test circuit 20 is connected, and the thermal sensor 13 of the tested motor 12 is connected with the thermal sensor resistance measurement circuit 21 . The inductance test loop 17 , the dielectric strength test loop 18 , the insulation resistance tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com