Heat transfer surface and microporous flow passages or small-hole flow passages integrated planar perforated-plate heat exchanger

A heat exchange surface, integrated technology, applied in the direction of heat exchanger type, indirect heat exchanger, fixed plate duct assembly, etc., can solve the problems of small heat exchange area, complicated construction and installation, and high cost, and achieve heat exchange area. Large, convenient appearance design, large heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

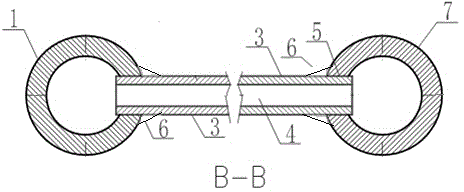

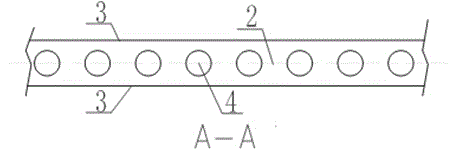

[0028] Embodiment 1: refer to image 3 As shown, the heat exchange surface 3 of the heat exchange orifice plate 2 is a flat structure, and a plurality of microholes or small hole flow channels 4 are arranged side by side in the heat exchange orifice plate 2, and the cross section of the microhole or small hole flow channels 4 is circular Structure; the heat exchange surface 3 itself is the maintenance structure of the micropore or small hole flow channel 4.

Embodiment 2

[0029] Embodiment 2, with reference to Figure 4 As shown, the heat exchange surface 3 of the heat exchange orifice plate 2 is a flat structure, and a plurality of micropores or small hole flow channels 4 are arranged side by side in the heat exchange orifice plate 2, and the cross section of the micropore or small hole flow channels 4 is oval Structure; the heat exchange surface 3 itself is the maintenance structure of the micropore or small hole flow channel 4.

Embodiment 3

[0030] Embodiment 3, with reference to Figure 5 As shown, a plurality of micropores or small hole flow channels 4 are arranged side by side in the heat exchange orifice plate 2, and the cross section of the micropore or small hole flow channels 4 is an elliptical structure. The shape of the hole or small hole flow channel 4 is wavy; the heat exchange surface 3 itself is the maintenance structure of the micro hole or small hole flow channel 4 .

[0031] The working principle of the present invention is as follows:

[0032] 1. Heat absorption process from high temperature environment: the low temperature fluid in the collecting and distributing pipe 1 is distributed to the micropore or small hole flow channel 4 of the heat exchange orifice plate 2, and the heat exchange orifice plate through which the thinned low temperature liquid passes The overall heat exchange surface 3 of 2 forms a low-temperature heat exchange surface, which absorbs ambient heat from the high temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com