Control method and device for controlling cooling process in bar production line

A technology for controlling cooling and control methods, applied in manufacturing tools, heat treatment process control, heat treatment equipment, etc., can solve problems such as failure to provide automatic settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

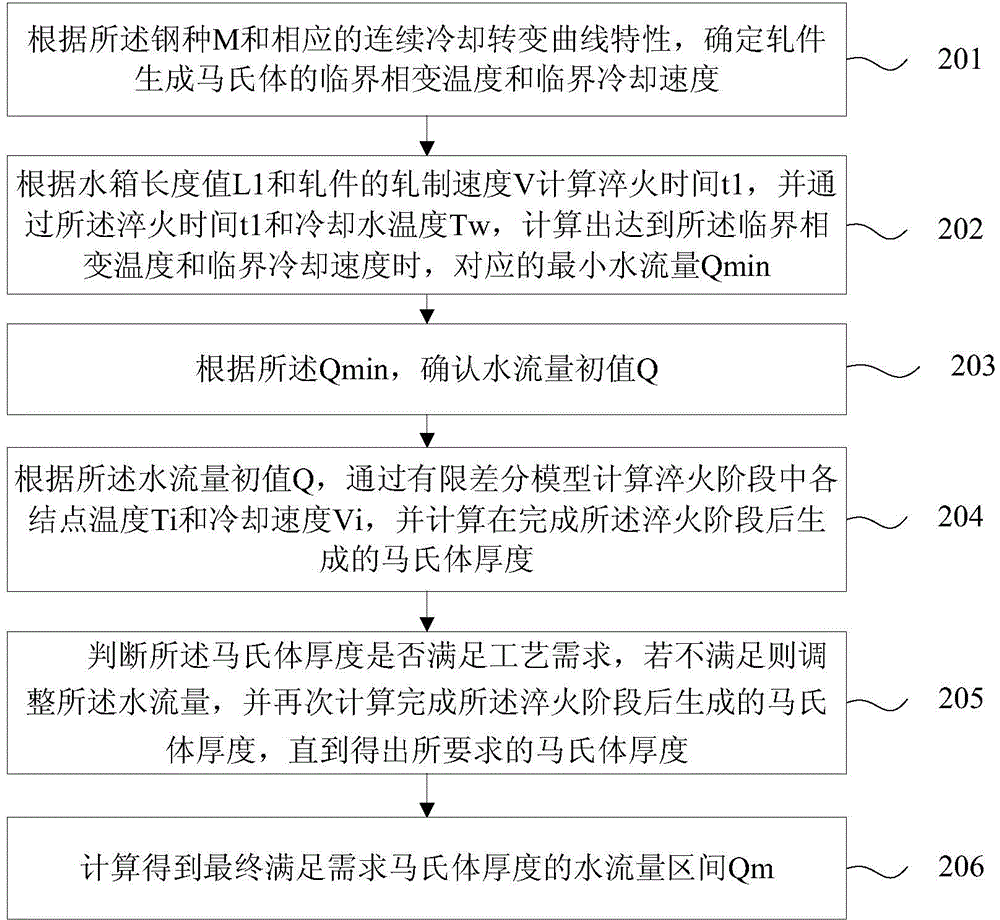

[0022] Such as figure 1 Shown is a flow chart of a control method for a controlled cooling process of a bar production line provided by an embodiment of the present invention. The method of this embodiment is applicable to various controlled cooling processes of a bar production line, especially for surface quenching and cooling of ribbed steel bars. Self-tempering process parameter setting, including: water flow size and quenching time. Depend on figure 1 It can be seen that an embodiment of a control method for a rod controlled cooling process provided by the present invention,

[0023] In step 201, according to the steel type M and the corresponding characteristics of the continuous cooling transformation curve, the critical phase transformation temperature and the critical cooling rate for forming martensite in the rolled piece are determined.

[0024] Such as Figure 4 As shown, it is a typical continuous cooling transformation curve characteristic (Continuous Cooling ...

Embodiment 2

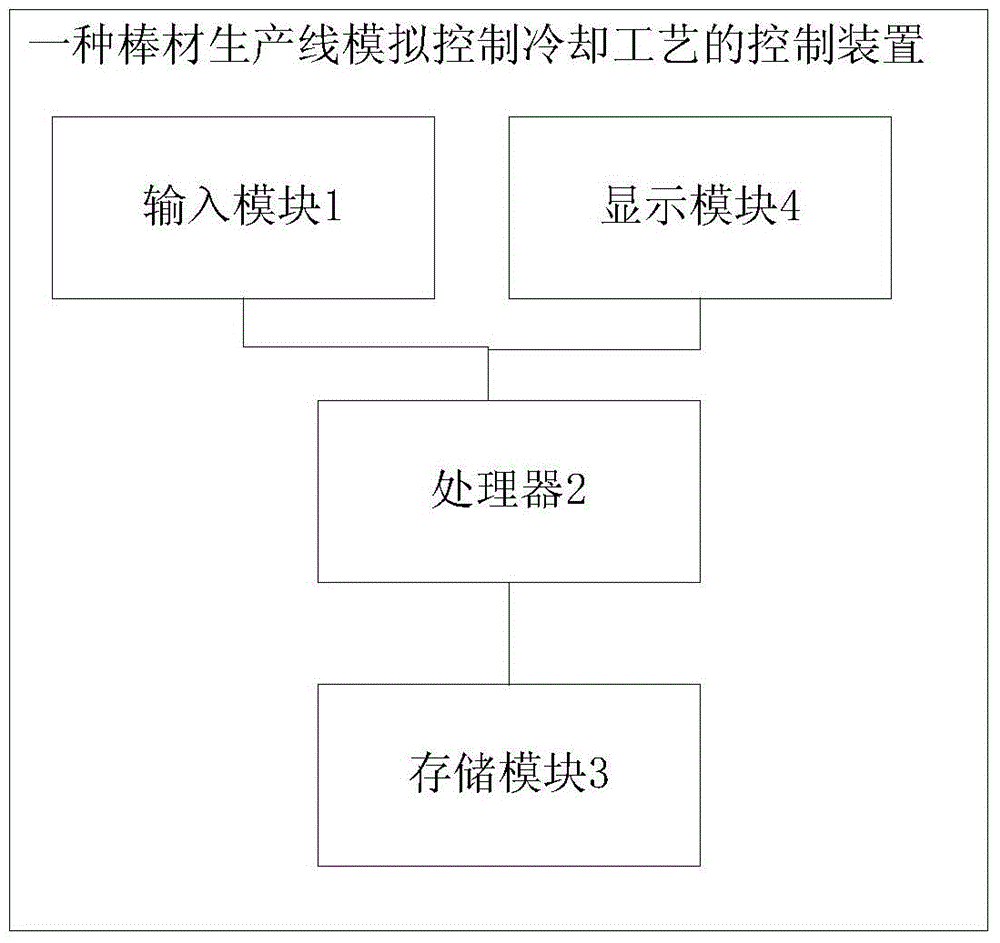

[0059] The embodiment of the present invention also provides a control device for controlling the cooling process of the bar production line, which is used for the operation control system, and the control system is used to realize the method steps of the first embodiment above, as image 3 As shown, the device includes an input module 1, a display module 4, a processor 2 and a storage module 3, specifically:

[0060] The input module 1 is configured to receive rolling process parameters input by users.

[0061] The processor 2 is used to determine the critical phase transformation temperature and the critical cooling rate at which martensite is produced on the surface of the rolled piece according to the steel type M and the corresponding continuous cooling transformation curve characteristics; according to the length value L1 of the water tank and the The rolling speed V calculates the quenching time t1, and through the quenching time t1 and the cooling water temperature Tw,...

Embodiment 3

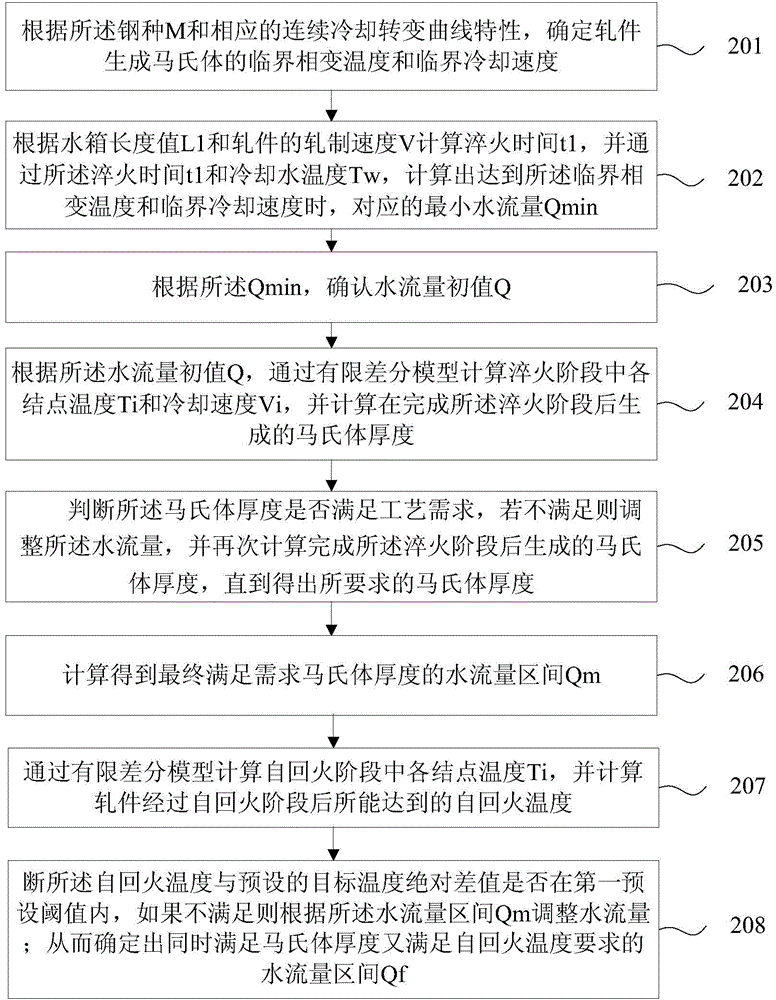

[0068] This embodiment is based on the execution steps of the main body in Embodiment 1, and combines one or more extended implementation methods introduced in Embodiment 1 to provide a flow chart of a relatively comprehensive control method for controlling the cooling process of the bar production line ,Such as Image 6 As shown, it specifically includes the following steps:

[0069] In step 301, start the control system software installed in the device in the second embodiment.

[0070] In step 302, the operator inputs the rolling process parameters through the display module 4 of the device, including: controlled cold-rolled piece specification D, rolling speed V, cooling water temperature Tw, quenching water tank length L1, steel type M, and so on.

[0071] In step 303, according to the steel type M and the corresponding characteristics of the continuous cooling transformation curve, the critical phase transformation temperature and the critical cooling rate for forming m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com