Direct high-temperature coke gasification technology and gasifier employed by same

A high-temperature coke and gasifier technology, applied in the field of coal gasification, to reduce consumption, eliminate environmental pollution and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

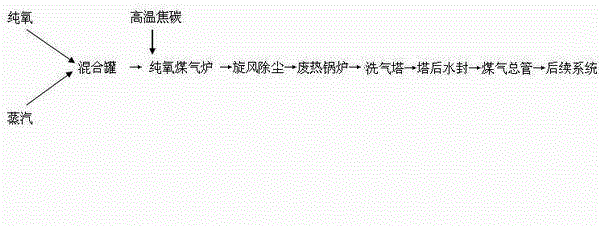

[0049] A high temperature coke direct gasification process, the steps of the process are as follows:

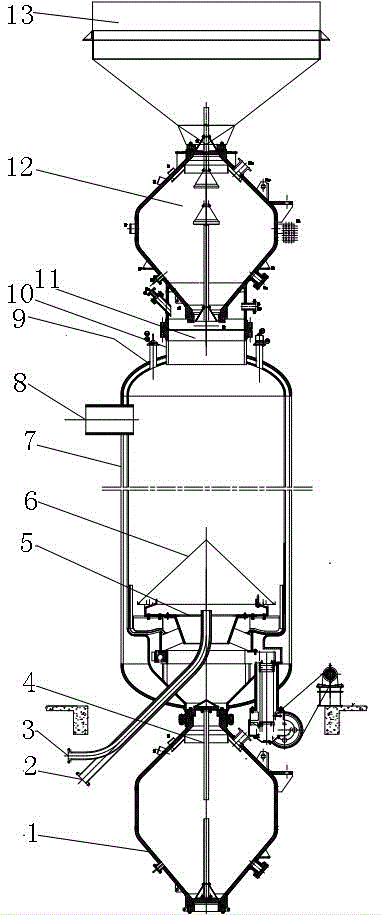

[0050] A) Use the high-temperature coke that has not been quenched to push the coke from the coke oven into the high-temperature coke tank, and send it to the lifting shaft by a tractor to be lifted to the top of the gasification furnace by the hoist;

[0051] B) The high-temperature coke tank is aligned with the high-temperature storage bin on the top of the furnace through the automatic alignment system and at the same time the discharge valve is opened to automatically drop high-temperature coke into the storage bin. The storage bin has the functions of storage, crushing and feeding at the same time, and can Realize automatic timing and quantitative addition of coke into the furnace;

[0052] C) The gasification agent oxygen used for gas production comes from the air separation process. The oxygen concentration is 40% according to the gas requirements of the subsequent pro...

Embodiment 2

[0056] A high temperature coke direct gasification process, the steps of the process are as follows:

[0057] A) Use the high-temperature coke that has not been quenched to push the coke from the coke oven into the high-temperature coke tank, and send it to the lifting shaft by a tractor to be lifted to the top of the gasification furnace by the hoist;

[0058] B) The high-temperature coke tank is aligned with the high-temperature storage bin on the top of the furnace through the automatic alignment system and at the same time the discharge valve is opened to automatically drop high-temperature coke into the storage bin. The storage bin has the functions of storage, crushing and feeding at the same time, and can Realize automatic timing and quantitative addition of coke into the furnace;

[0059] C) The gasification agent oxygen used for gas production comes from the air separation process. The oxygen concentration is 100% according to the gas requirements of the subsequent pr...

Embodiment 3

[0063] A high temperature coke direct gasification process, the steps of the process are as follows:

[0064] A) Use the high-temperature coke that has not been quenched to push the coke from the coke oven into the high-temperature coke tank, and send it to the lifting shaft by a tractor to be lifted to the top of the gasification furnace by the hoist;

[0065] B) The high-temperature coke tank is aligned with the high-temperature storage bin on the top of the furnace through the automatic alignment system and at the same time the discharge valve is opened to automatically drop high-temperature coke into the storage bin. The storage bin has the functions of storage, crushing and feeding at the same time, and can Realize automatic timing and quantitative addition of coke into the furnace;

[0066] C) The gasification agent oxygen used for gas production comes from the air separation process. The oxygen concentration is 80% according to the gas requirements of the subsequent pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com