Novel high-scattering quantum dot fluorescent powder and preparation method thereof

A technology of scattering quantum and phosphor powder, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as being unsuitable for large-scale industrial production, limited number of quantum dots, unable to meet demand, etc., to achieve suitable for large-scale production, color Adjustable, superior optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

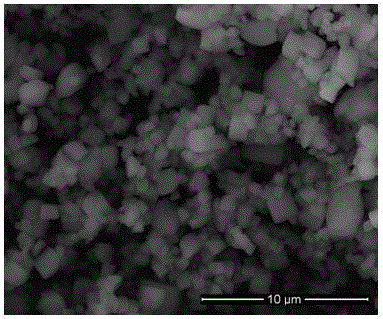

[0023] A new type of high-scattering quantum dot phosphor is prepared by using sodium chloride as the matrix and CdSe / ZnS quantum dots as the luminescent center.

[0024] The preparation method of the above-mentioned novel high-scattering quantum dot phosphor includes the following steps:

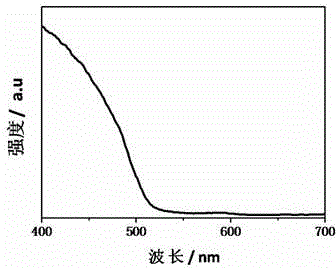

[0025] Transfer 3g of sodium chloride powder into a beaker, add 300ml of distilled water, stir for 10 minutes, then add 30mg of CdSe / ZnS (PL 607 nm) quantum dots, stir magnetically at room temperature for 7 minutes, and then ultrasonicate for 5 minutes (ultrasonic power 100W); Then magnetic stirring at room temperature for 15 minutes, the mixed solution was transferred to a spray drying device for spray drying at 150° C. to obtain a powdery QDNaCl phosphor product. CdSe / ZnS quantum dots can be prepared by referring to the following literatures: Changhua Zhou, Huaibin Shen, Yi Guo, Li Xu, Jinzhong Niu, Zhijun Zhang, Zuliang Du, Jianmin Chen, Lin Song Li, A versatile method for the preparatio...

Embodiment 2

[0028] A new type of high-scattering quantum dot fluorescent powder is prepared with nano-scale silicon dioxide as the matrix and CdSe / ZnS quantum dots as the luminescent center.

[0029] The preparation method of above-mentioned novel high-scattering quantum dot fluorescent powder, it comprises the steps:

[0030] Take 3g of silica powder (particle size 30nm) into a beaker, add 500ml of distilled water, stir magnetically at room temperature for 40 minutes, sonicate for 10 minutes (ultrasonic power 100W), stir magnetically at room temperature for 15 minutes, then add 15mg CdSe to the beaker / ZnS (PL 607 nm) quantum dots, first magnetically stirred at room temperature for 15 minutes, then ultrasonically for 20 minutes (ultrasonic power 100W), then magnetically stirred at room temperature for 20 minutes, then transferred the mixed solution to a spray drying device and spray-dried at 150°C. Obtain powdered QDSiO 2 Phosphor products.

[0031] Take a small amount of the above-menti...

Embodiment 3

[0033] A novel high-scattering quantum dot fluorescent powder is prepared by using potassium chloride as a matrix and CdSe / ZnS quantum dots as luminescent centers.

[0034] The preparation method of above-mentioned novel high-scattering quantum dot fluorescent powder, it comprises the steps:

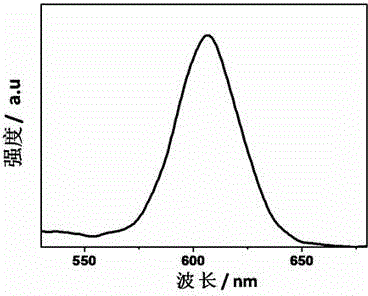

[0035] Transfer 3g of potassium chloride powder into a beaker, add 250ml of distilled water, stir magnetically at room temperature for 5 minutes, then add 20mg of CdSe / ZnS (PL 530 nm) quantum dots, stir magnetically at room temperature for 2 minutes, and then sonicate for 4 minutes (ultrasonic power 100W); then magnetically stirred at room temperature for 9 minutes, and the mixed solution was transferred to a spray drying device and spray-dried at 150°C to obtain a powdered QDKCl phosphor product.

[0036] Use a fluorescence spectrometer to test the emission spectrum of the above-mentioned products, the excitation light wavelength is 365nm, and the obtained results are as follows Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com