A method for separating rare earth phosphor from electronic waste powder

A technology of electronic waste and rare earth phosphors, applied in chemical instruments and methods, luminescent materials, recycling technology, etc., can solve the problems of unsatisfactory quality content of rare earth oxides, pollution of water sources, soil and vegetation, and difficulty in separation, etc. problems, to achieve the effect of solving poor separation effect, solving difficult operation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment includes the following steps:

[0026] Step 1. Pass the electronic waste powder through a 100-mesh sieve, and take the under-sieve to obtain fine particles of electronic waste; the electronic waste powder is composed of the following components in mass percentages: screen cone glass 50%, graphite 7%, 20% of rare earth phosphor, 7% of aluminum foil, 11% of nano-alumina and 5% of dust; the mass content of rare earth oxide in the rare earth phosphor is not less than 30%;

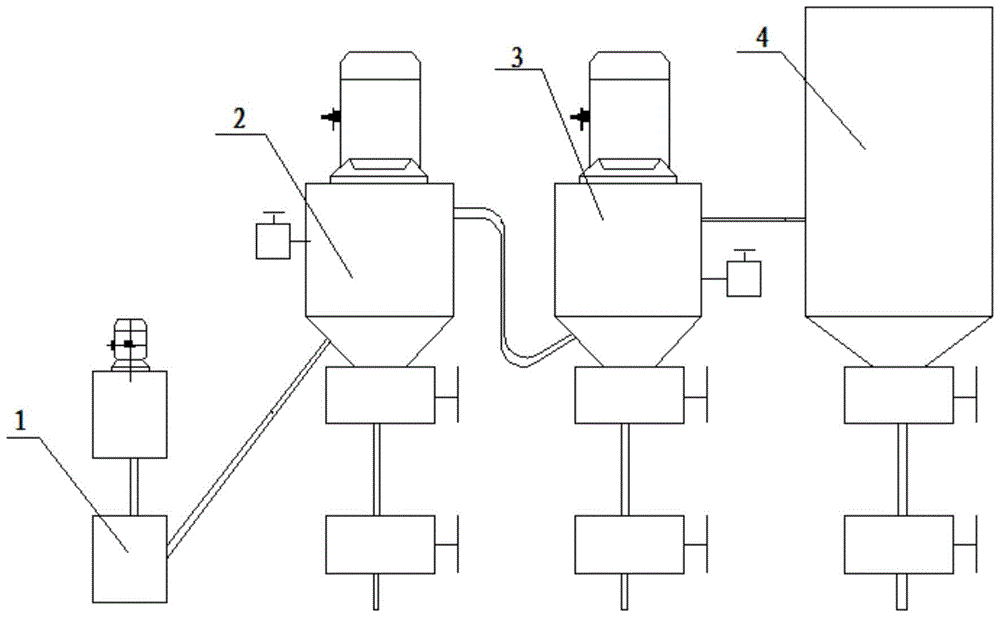

[0027] Step 2. The electronic waste fine particles described in step 1 are transported to the fine particle separation device for primary separation, and the primary separation material is collected at the discharge port of the fine particle separation device, and then the primary separation material is Return to the fine particle separation device for secondary separation, and collect the secondary separation material at the discharge port of the fine particle separation device; figure ...

Embodiment 2

[0031] This embodiment includes the following steps:

[0032] Step 1. Pass the electronic waste powder through a 150-mesh sieve, and take the under-sieve to obtain fine particles of electronic waste; the electronic waste powder is composed of the following components in mass percentages: screen cone glass 45%, graphite 5%, 27% of rare earth phosphor, 8% of aluminum foil, 10% of nano-alumina and 5% of dust; the mass content of rare earth oxide in the rare earth phosphor is not less than 30%;

[0033] Step 2. The electronic waste fine particles described in step 1 are transported to the fine particle separation device for primary separation, and the primary separation material is collected at the discharge port of the fine particle separation device, and then the primary separation material is Return to the fine particle separation device for secondary separation, and collect the secondary separation material at the discharge port of the fine particle separation device; figure ...

Embodiment 3

[0037] This embodiment includes the following steps:

[0038] Step 1. Pass the electronic waste powder through a 200-mesh sieve, and take the under-sieve to obtain fine particles of electronic waste; the electronic waste powder is composed of the following components in mass percentages: screen cone glass 40%, graphite 5%, 30% of rare earth phosphor, 5% of aluminum foil, 15% of nano-alumina and 5% of dust; the mass content of rare earth oxide in the rare earth phosphor is not less than 30%;

[0039] Step 2. The electronic waste fine particles described in step 1 are transported to the fine particle separation device for primary separation, and the primary separation material is collected at the discharge port of the fine particle separation device, and then the primary separation material is Return to the fine particle separation device for secondary separation, and collect the secondary separation material at the discharge port of the fine particle separation device; figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com