Cross-linked polyvinyl chloride foam and its preparation method

A technology of cross-linked polyvinyl chloride and foam, which is applied in the field of foam materials, can solve the problems of long time consumption, achieve the effects of improving quality and heat resistance, improving moisture diffusion, and reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

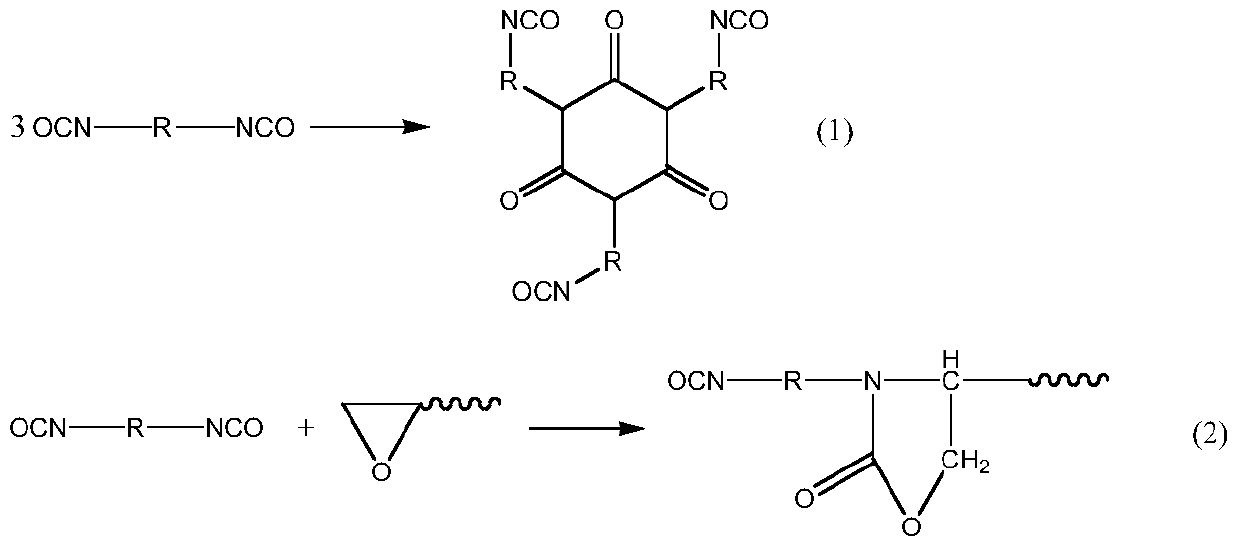

Method used

Image

Examples

preparation example Construction

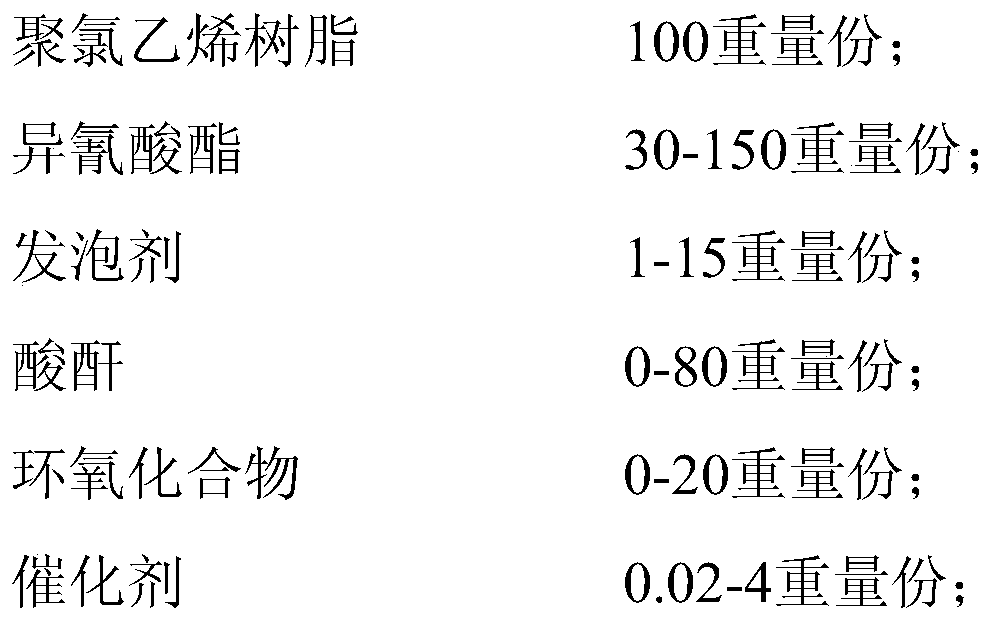

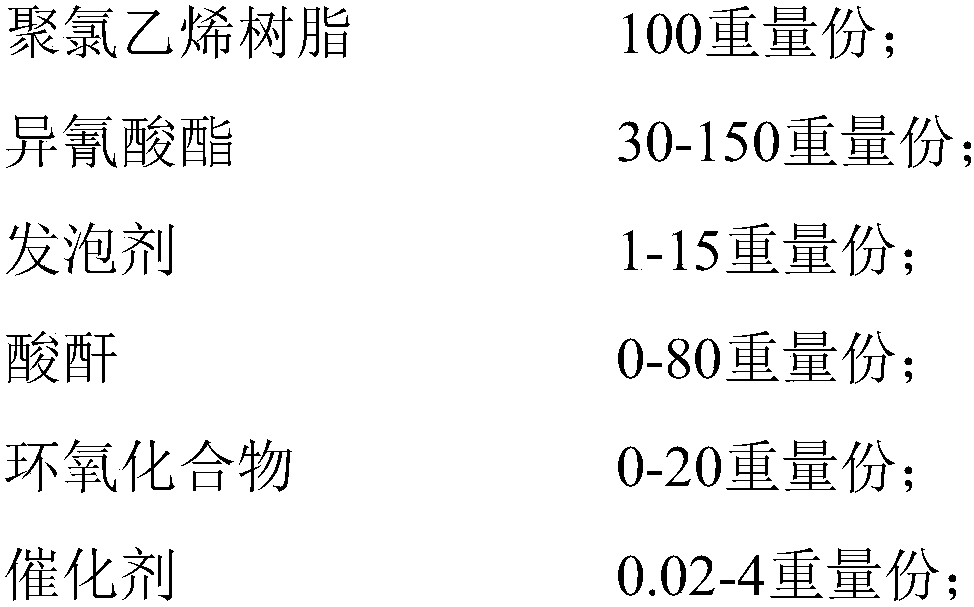

[0040] The preparation method of the cross-linked polyvinyl chloride foam includes the following steps:

[0041] Step 1. After weighing the components according to the composition and parts by weight, the components are mixed uniformly to obtain a paste material;

[0042] Wherein, when the catalyst is one or more of indole, sodium caprylate, potassium isooctanoate, potassium oleate, and potassium stearate, the components can be mixed in any order, as long as they are evenly mixed;

[0043] When the catalyst contains N',N”,N”'-tris(dimethylaminopropyl) symmetric hexahydrotriazine, because N',N”,N”'-tris(dimethylaminopropyl) Symmetric hexahydrotriazine has strong catalytic activity. When it is compounded with isocyanate, the reaction temperature rises quickly. If there are other components in the environment, the viscosity of other components will rise quickly, and even good mixing will not be completed. ; So when the catalyst contains N',N”,N”'-tris (dimethylaminopropyl) symmetric he...

Embodiment 1

[0054] The crosslinked polyvinyl chloride foam consists of 100 parts by weight of PVC resin, 50 parts by weight of liquefied MDI, 20 parts by weight of bisphenol A glycidyl ether, 1 part by weight of potassium stearate and 15 parts by weight of foaming agent H.

[0055] The preparation method of the above cross-linked polyvinyl chloride foam:

[0056] Mix 100 parts by weight of PVC resin, 50 parts by weight of liquefied MDI, 20 parts by weight of bisphenol A glycidyl ether, 1 part by weight of potassium stearate and 15 parts by weight of blowing agent H, and add them to a 22mm thick mold. Carry out foaming and molding at a temperature of 200°C and a pressure of 19MPa, heat preservation for 660s, and cool to 71°C to open the mold to obtain a pre-foamed body;

[0057] Then place the obtained pre-foamed body in 95℃ hot water for secondary expansion for 40 minutes, then place the secondary expanded foam in 65℃ saturated steam for curing and crosslinking, and use infrared absorption spect...

Embodiment 2

[0059] Cross-linked polyvinyl chloride foam, composed of: 30 parts by weight of TDI, 40 parts by weight of methylhexahydrophthalic anhydride, 40 parts by weight of tetrahydrophthalic anhydride, 0.2 parts by weight of N',N”,N”'-tris(dimethylamino) Propyl) symmetric hexahydrotriazine, 100 parts by weight of PVC resin and 1 part by weight of AC.

[0060] The preparation method of the above cross-linked polyvinyl chloride foam:

[0061] First, 30 parts by weight of TDI, 40 parts by weight of methylhexahydrophthalic anhydride, and 40 parts by weight of tetrahydrophthalic anhydride are mixed uniformly to obtain a mixture, and then the mixture is quickly poured into 0.2 parts by weight of N', N", N"'- In a container of tris(dimethylaminopropyl) symmetric hexahydrotriazine, stir and mix well, then pour 100 parts by weight of PVC resin and 1 part by weight of AC into the container, mix well, and obtain a paste material;

[0062] Put the paste material into a 22mm thick mold with a cavity, fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com