New-style pneumatic jack

A pneumatic jack, a new type of technology, applied in the direction of lifting devices, etc., can solve the problem of low safety factor, achieve high safety factor, extremely fast lifting and lowering, and high promotional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

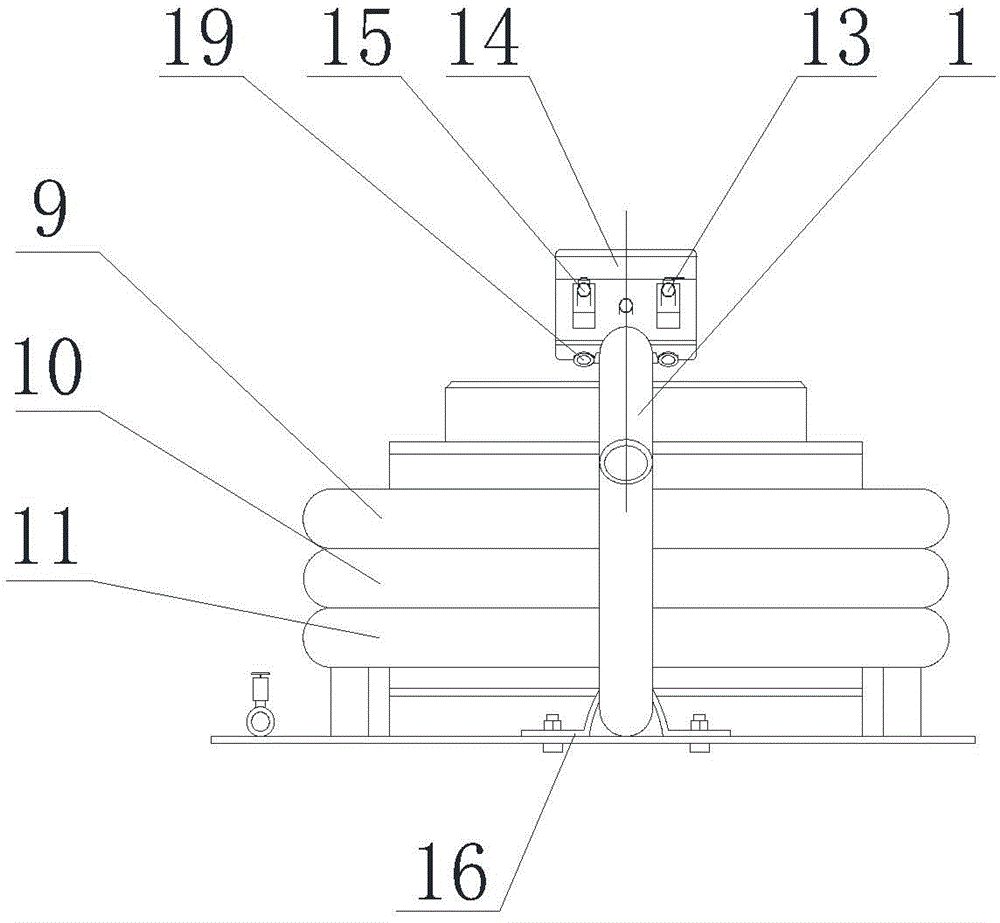

[0024] according to the above Figure 1 to Figure 4 The illustrated embodiment installs the new pneumatic jack of the cost embodiment. The jack consists of an upper bag (9), a middle bag (10) and a lower bag (11) to form a rubber air bag part, and the air bag part is fixed on the base (7) for each air bag Air valve (4) is reserved on it. Two pneumatic shut-off valves (8) are respectively installed on the front end of the base (7), and the adjacent air bags are connected by the pneumatic shut-off valves (8) through the ventilation pipes (3). Pulley (12) is installed in base (7) left end. The lock nut (6) is located at the right end of the base (7) and is used to fix the ventilation pipe (3). Pull bar (1) is positioned at the right end of base (7), and pull bar (1) is fixed on the base (7) with bent steel plate (16) and bolt (5). The front end of the pull rod (1) is equipped with a baffle (14), the inflation valve (15) and the deflation valve (13) are located above the baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com