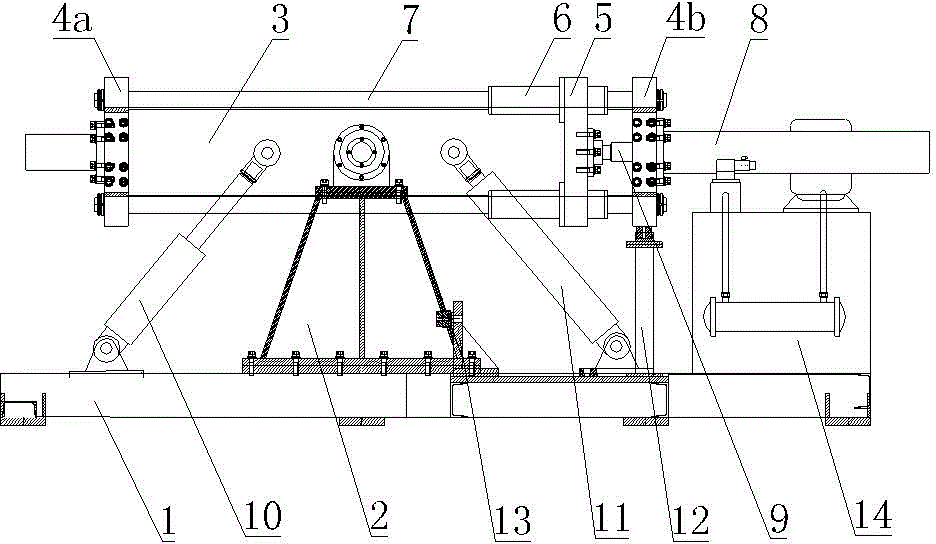

Inclinable double-gravity casting machine

A casting machine, dual technology, applied in casting equipment, equipment for feeding molten metal into molds, metal processing equipment, etc., can solve the problems of unsatisfactory rotation effect, unstable operation, laborious rotation, etc. The effect of good reliability and flexible rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

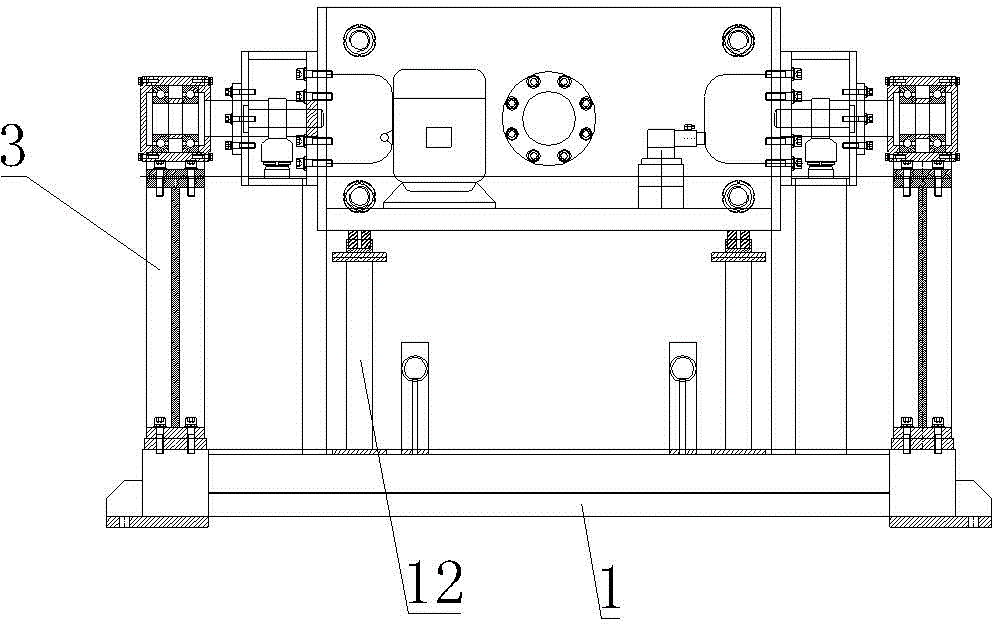

[0012] See figure 1 , figure 2 , the present invention includes a support 2 installed on the base 1, the support 2 articulated formwork 3, the two ends of the formwork 3 are respectively provided with fixed templates 4a, 4b, and guide columns 7 are arranged between the fixed templates 4a, 4b The movable template 5 is correspondingly provided with a guide sleeve 6, and the movable template 5 is mounted on the guide pillar 7 through the sliding fit of the guide post 7 and the guide sleeve 6. The piston rod 9 of the mold cylinder 8 is fixedly connected to the movable formwork 5, and the side of the base 1 corresponding to the mold frame 3 is respectively provided with a push-pull cylinder 11 and a contraction cylinder 10, and the piston rods of the push-pull cylinder 11 and the contraction cylinder 10 are movable and hinged mold frame 3 , both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com