Method for carrying out evaporative pattern casting on dry cylinder liner machine body and model thereof

A lost foam, dry technology, applied in the direction of casting molding equipment, molds, mold components, etc., can solve the problems of molten metal leakage, sand filling is not solid, complex geometry, etc., to improve quality and yield, operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A method for casting a dry-type cylinder liner body by the lost foam method, specifically comprising the following steps:

[0027] (A) The white mold of the dry cylinder liner body is prepared by foaming material;

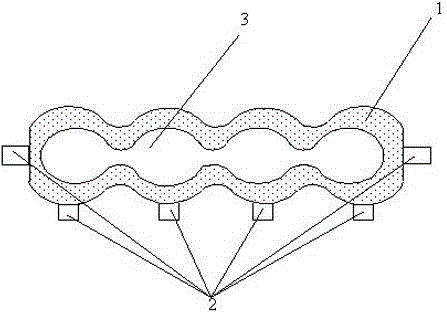

[0028] (B) The coated sand core 1 of the water jacket part of the dry-type cylinder liner body is prepared by using coated sand, and several positioning core heads 2 are arranged on the coated sand core 1, such as figure 1 shown;

[0029] (C) Put the coated sand core with the positioning core head into the corresponding water jacket part of the white mold, wherein the water jacket part is the part between the cylinder liner and the shell of the dry cylinder liner body;

[0030] (D) Bonding the white molds together.

[0031] The positioning core 2 is located at the side process hole of the water jacket, one end of the positioning core 2 is connected to the coated sand core 1, and the other end extends out of the side process hole.

[0032] The preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com