Adsorption material modified by photosensitive polymer and its preparation method and application

A technology of photosensitive polymer and adsorption material, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of poor oil retention, poor oil-water selectivity, low reaction efficiency, etc., and achieves simple and convenient polymer modification methods. Good oil-water selectivity and the effect of improving oil absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Synthesis of photosensitive monomer spiropyran 2-methacrylate.

[0042] Under nitrogen protection, dissolve 1g (2.83mmol) spiropyran (SP-OH) in 15mL of anhydrous dichloromethane, add 300μl (3.1mmol) 2-methacryloyl chloride dropwise, and react under ice bath conditions After 12 hours, after the reaction was over, dichloromethane was removed by rotary evaporation, and the resulting crude product was purified by silica gel column chromatography (developing solvent was petroleum ether:dichloromethane=1:2), and 0.4 g of yellow solid was obtained after vacuum drying, namely Spiropyran 2-methacrylate (SPMA).

[0043]

[0044] 1 H-NMR (400MHz, CDCl 3 ), δ (ppm): 7.97-8.05 (m, 2H), 7.17-7.24 (m, 1H),7.09 (d, 1H), 6.89 (dd, 2H), 6.74 (dd, 2H), 6.07 (d, 1H), 5.87 (d, 1H), 5.56(d, 1H), 4.3 (t, 2H), 3.37-3.62 (m, 2H), 1.92 (s, 3H), 1.28 (s, 3H), 1.16 (s ,3H).

Embodiment 2

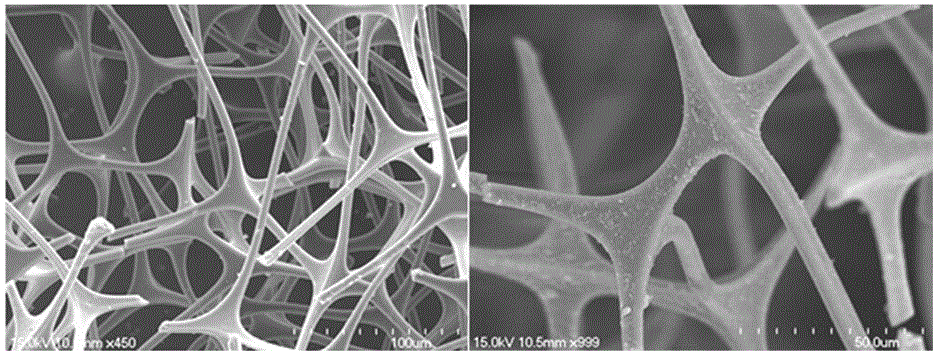

[0045]Example 2: Vinyltrichlorosilane modification of melamine foam.

[0046] Dissolve 1 g of vinyltrichlorosilane in 99 g of toluene to obtain a 1% by weight vinyltrichlorosilane toluene solution for use.

[0047] Cut melamine foam (purchased from Zhangjiagang Mingjie Sponge Products Co., Ltd.) into 2cm×2cm×2cm squares (65mg in weight), immerse in 26g of the above-mentioned vinyltrichlorosilane toluene solution, take out the foam after 20 minutes , squeeze out the silane solution in it, then wash the foam repeatedly with 50mL ethanol for 3 times, and dry it in an oven at 100°C to obtain vinyltrichlorosilane-modified melamine foam (66.5mg in weight).

Embodiment 3

[0048] Example 3: Copolymerization of spiropyran monomer SPMA and vinyl trichlorosilane modified melamine foam.

[0049] The feeding amount of various reactants in Example 1 was scaled up year-on-year, and 1 g of SPMA was prepared according to the same procedure. Weigh 840mg (2.1mmol) of SPMA, 5mg (0.03mmol) of AIBN and dissolve in 28.5g of DMF to obtain 29.345g of copolymer solution for use.

[0050] Submerge the vinyltrichlorosilane-modified melamine foam (2cm×2cm×2cm, 65.5mg) obtained in Example 2 into the above-mentioned copolymerization solution, squeeze repeatedly to make the copolymerization solution fully contact with the foam, and then, under the protection of argon, React at 70°C for 12 hours. After the reaction, take out the foam, squeeze out the solution, wash the foam three times with 50mL n-hexane, and finally dry it in an oven at 100°C to obtain the SPMA photosensitive polymer-modified melamine foam material.

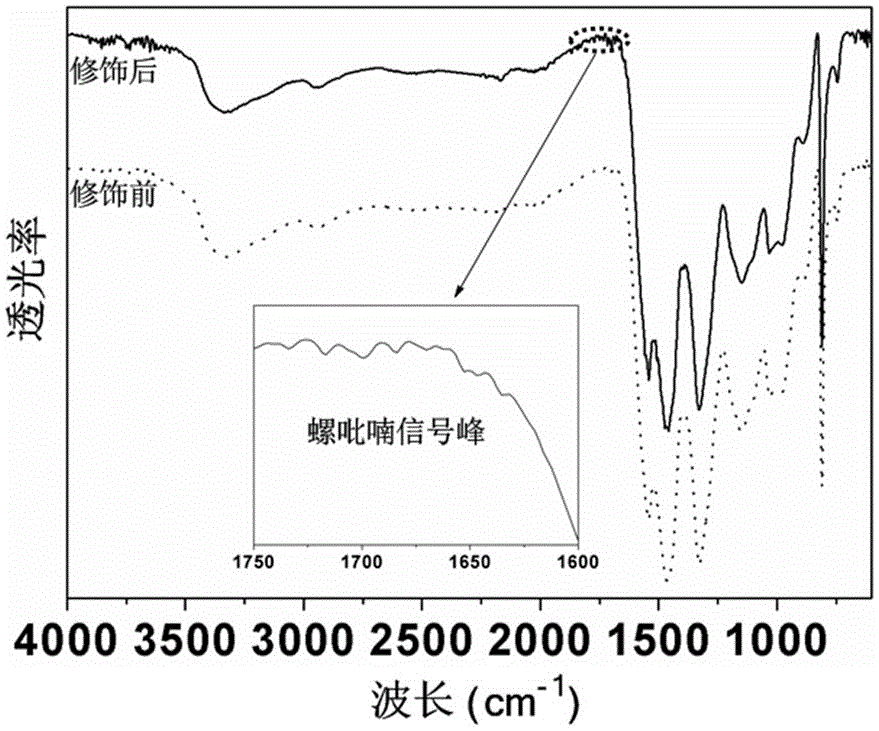

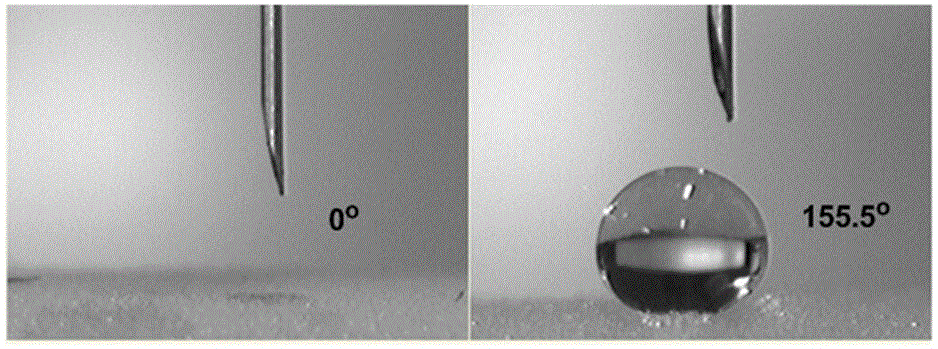

[0051] The success of photopolymer modification o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com