Butyl rubber composite gel oil-absorbing material and preparation method thereof

A technology of butyl rubber and composite gel, which is applied in the field of butyl rubber composite gel oil-absorbing material and its preparation, can solve the problems of long processing time, low recycling rate, application limitation and the like, and achieves large adsorption capacity and simple process. , the effect of forming fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A butyl rubber composite gel oil-absorbing material, the preparation method is as follows:

[0028] (1) Crush the butyl rubber, weigh 5g and dissolve it in 100mL chloroform and let it stand for a period of time. When the rubber becomes transparent, the butyl rubber has been fully dissolved and a rubber solution is obtained;

[0029] (2) In the rubber solution, 0.5g of accelerator octylphenol formaldehyde resin and 0.01g of p-benzoquinone dioxime were ultrasonically dispersed, and then 0.2mL of crosslinking agent disulfide dichloride was added with a pipette, Dispense the mixed solution into petri dishes, cover and react at ambient temperature for 12 hours;

[0030] (3) After the reaction is completed, the obtained composite gel material is alternately washed with toluene and methanol, at least twice each; then, dried in a fume hood at room temperature to obtain the butyl rubber composite gel oil-absorbing material.

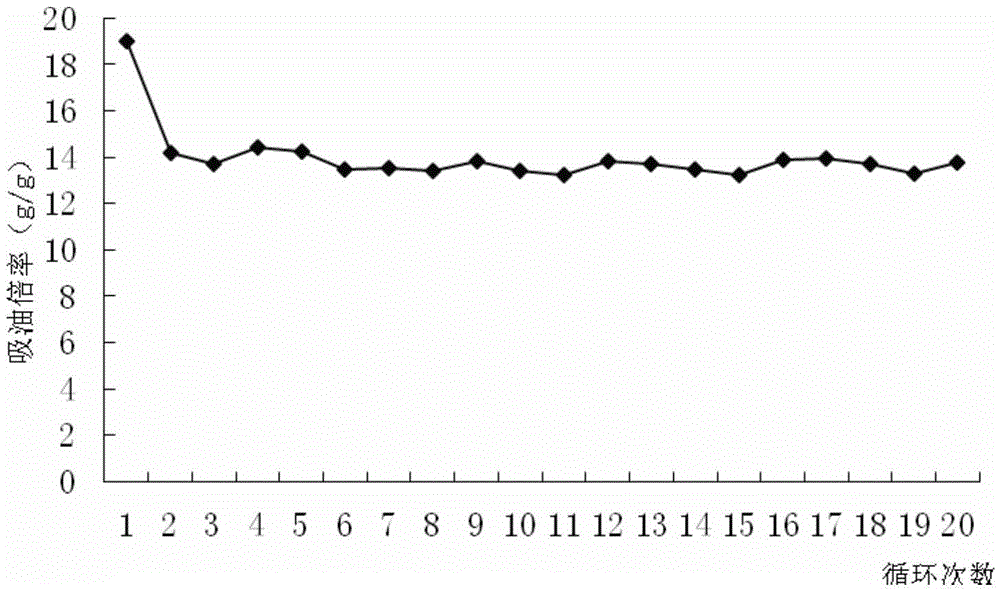

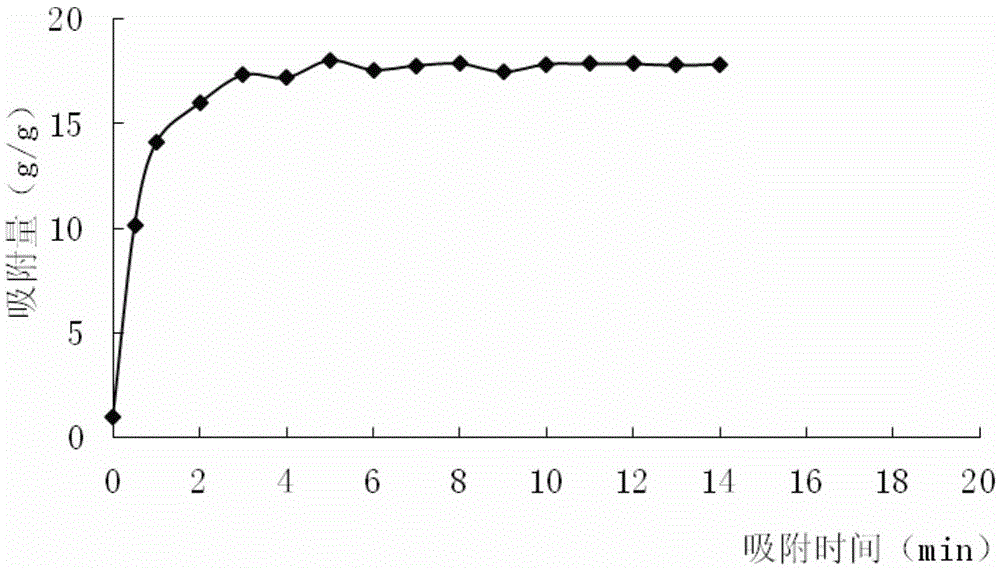

[0031] The fully dried oil-absorbing material is immersed in ...

Embodiment 2

[0040] A butyl rubber composite gel oil-absorbing material, the preparation method is as follows:

[0041] (1) Crush the butyl rubber, weigh 5g and dissolve it in 50mL chloroform and let it stand for a period of time. When the rubber becomes transparent, the butyl rubber is fully dissolved and a rubber solution is obtained;

[0042] (2) In the rubber solution, add 0.3g of accelerator octylphenol formaldehyde resin and 0.005g of p-benzoquinone dioxime, disperse them ultrasonically, and then add 0.2mL of crosslinker disulfide dichloride with a pipette, Dispense the mixed solution into petri dishes, cover and react for 10 hours;

[0043] (3) After the reaction is completed, the obtained composite gel material is alternately washed with toluene and methanol, at least twice each; then, dried in a fume hood at room temperature to obtain the butyl rubber composite gel oil-absorbing material.

[0044] The oil-absorbing material obtained in this example has a water absorption rate of 0.32g / g a...

Embodiment 3

[0046] A butyl rubber composite gel oil-absorbing material, the preparation method is as follows:

[0047] (1) Crush the butyl rubber, weigh 5g and dissolve it in 150mL chloroform, and let it stand for a period of time. When the rubber becomes transparent, the butyl rubber has been fully dissolved and a rubber solution is obtained;

[0048] (2) In the rubber solution, add 0.7g of accelerator octylphenol formaldehyde resin and 0.02g of p-benzoquinone dioxime, disperse them ultrasonically, and then add 0.5mL of crosslinking agent disulfide dichloride with a pipette, Dispense the mixed solution into petri dishes, cover and react at ambient temperature for 15 hours;

[0049] (3) After the reaction is completed, the obtained composite gel material is alternately washed with toluene and methanol, at least twice each; then, dried in a fume hood at room temperature to obtain the butyl rubber composite gel oil-absorbing material.

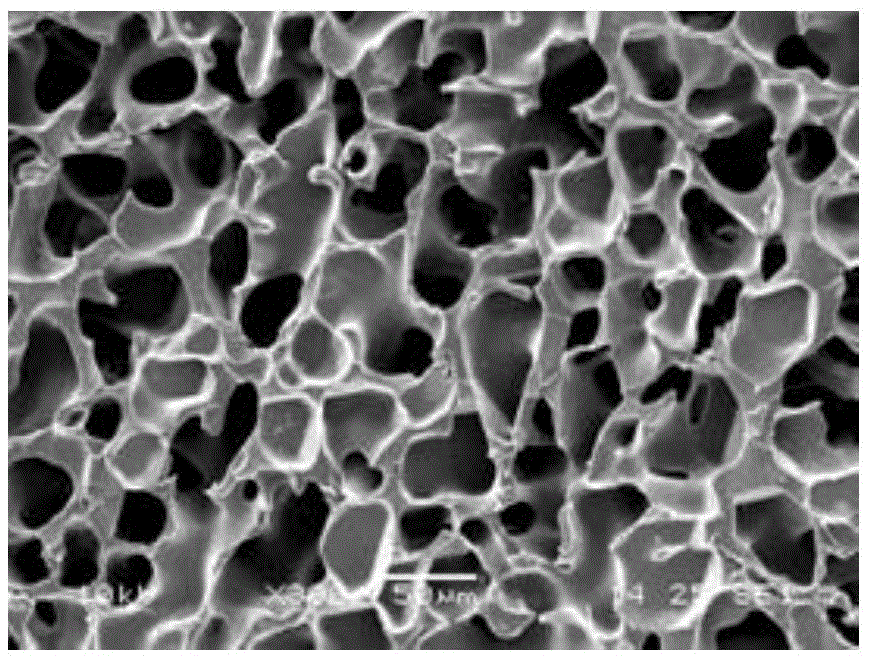

[0050] image 3 The SEM image of the obtained butyl rubber com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com