Externally heated heat loading device capable of rapidly heating

An external heating, thermal loading technology, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of low temperature rise rate, small maximum heating temperature and temperature rise rate, poor production continuity, etc. Thermal efficiency, the effect of improving heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

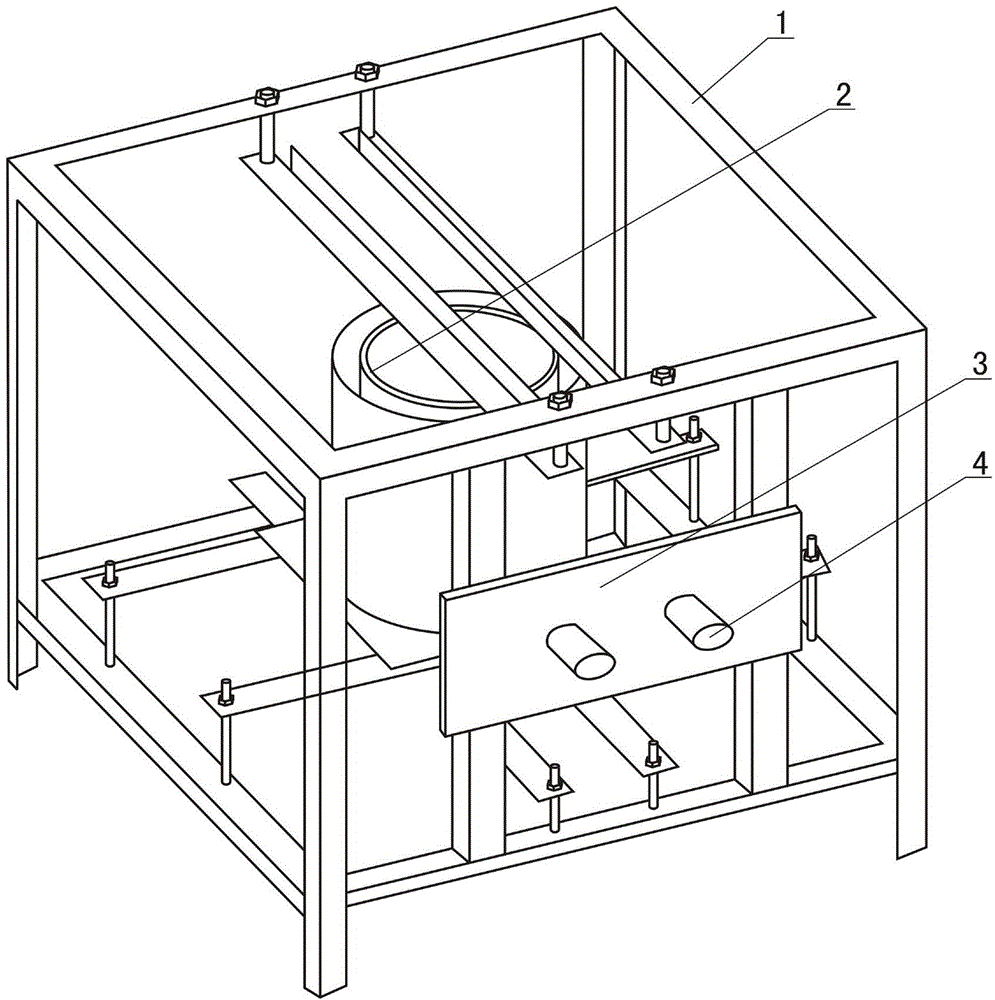

[0019] Such as figure 1 As shown, the external heating type thermal loading device 2 of the present invention is installed on the frame 1 during application, and the frame 1 is also equipped with a terminal block 3 and a terminal post 4 located on the terminal block 3. The power connection terminal of the external heating type heat loading device 2 is correspondingly connected with the terminal post 4, so that the external heating type heat loading device 2 can be powered on. illustrate, figure 1 The external heating type heat loading device 2 is only a schematic diagram, and figure 2 The specific structure of the device looks different, but they are all the same device.

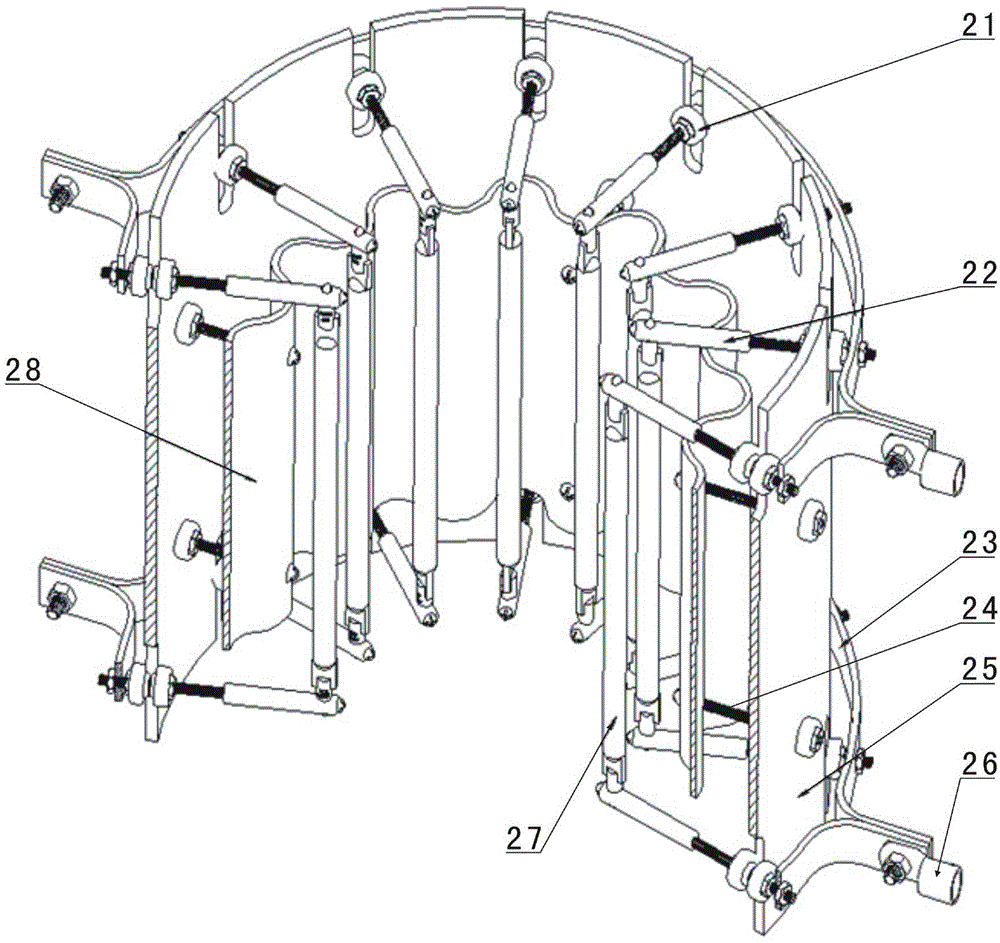

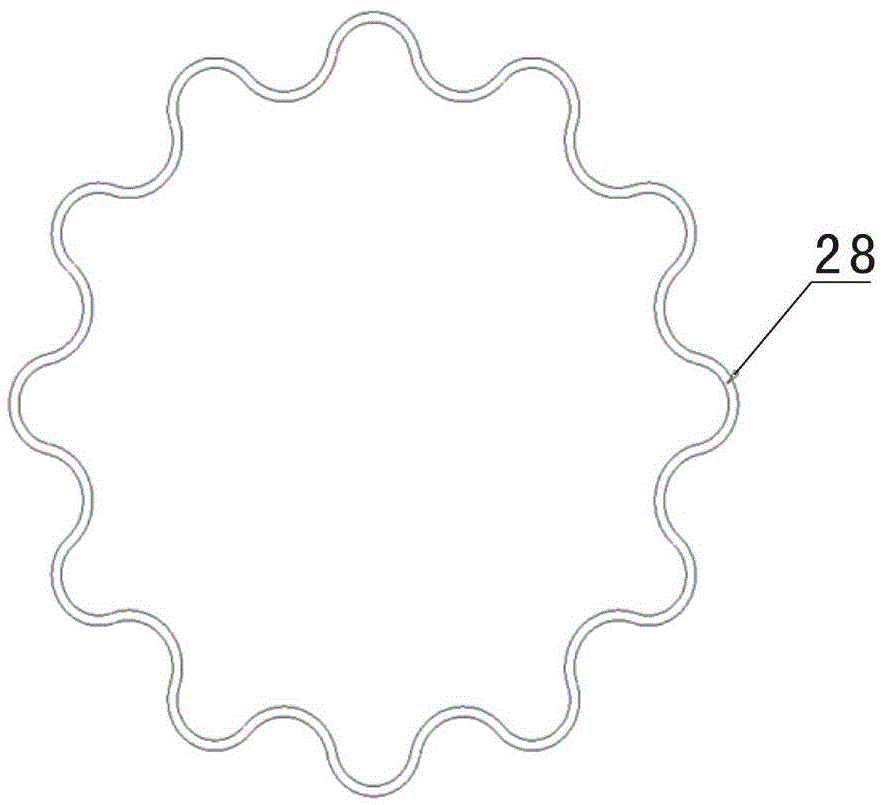

[0020] Such as figure 2 and image 3 As shown, the rapid heating-up external heat-loading device of the present invention includes a quartz lamp tube 27, a lamp tube clamp 22, an aluminum cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com