Long-service-life Chinese lute string

A long-life, pipa technology, applied in stringed instruments, instruments, musical instruments, etc., can solve the problems of fatigue damage, short service life, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The long-life pipa string of the present invention, wherein the lute string is a layered composite structure, the inner core of the layered composite structure is a steel wire, and the outer surface of the steel wire inner core is sprayed with supersonic flame spraying technology to prepare a layer with a thickness of The 260-300 μm thick metal-ceramic composite coating is coated with a copper-based alloy intermediate layer on the outside of the coating of the steel wire inner core, and a nylon outer layer is arranged on the outer surface of the intermediate layer.

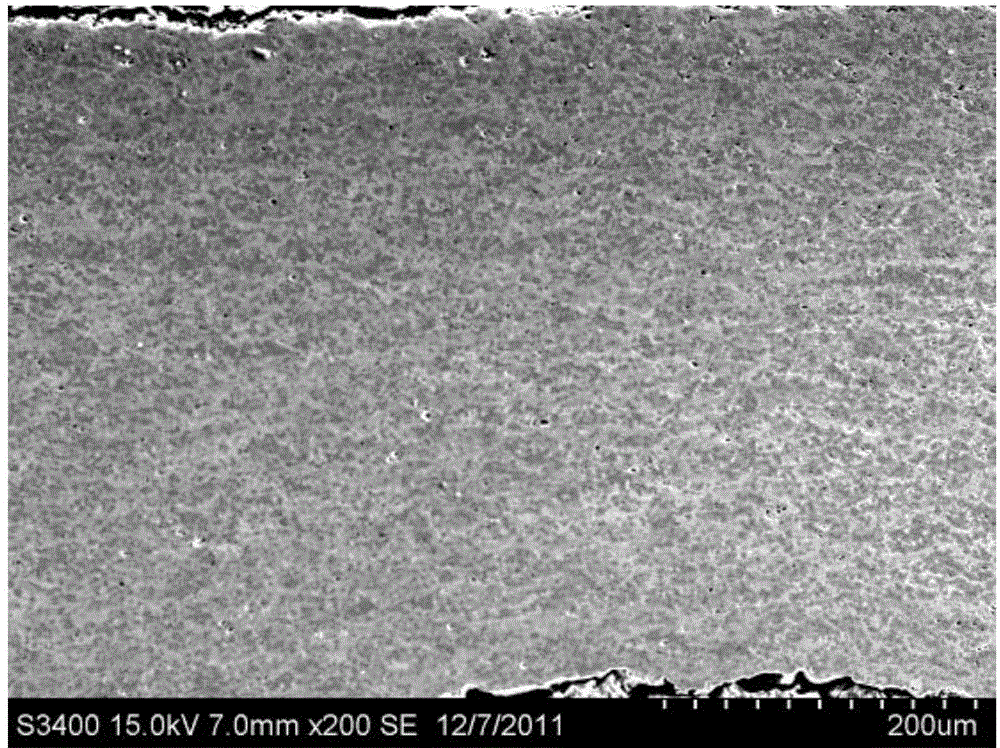

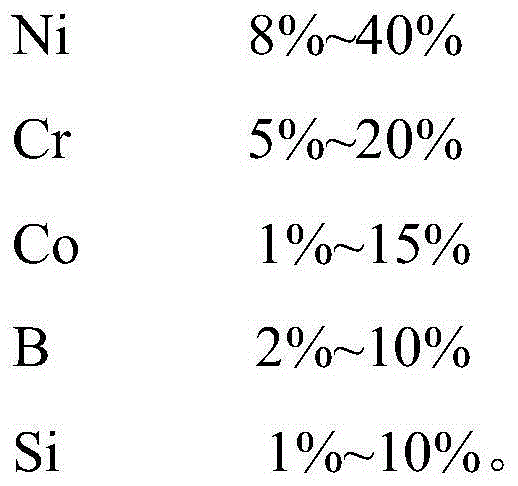

[0031] Wherein the metal-ceramic composite coating is composed of the following components, wherein each component is in mass percentage, WC 22%, TiO 2 18%, Ni 20%, Cr 14%, Co 14%, B 5%, Si 7%, using scanning electron microscope to detect the morphology of the coating, such as figure 1 shown. from figure 1 It can be seen from the figure that the coating has high density and few voids, which are almost inv...

Embodiment 2

[0036] The long-life lute string of the present invention, wherein the lute string is a layered composite structure, the inner core of the layered composite structure is a steel wire twisted rope formed by 7 steel wires, and supersonic flames are used on the outer surface of each steel wire Spraying technology sprays and prepares a layer of cermet composite coating with a thickness of about 280 μm, and then twists each other to form an inner core. A copper-based alloy intermediate layer is provided on the outer surface of the steel wire inner core, and a copper-based alloy intermediate layer is provided on the outer surface of the intermediate layer. Has a nylon exterior.

[0037] Wherein the metal-ceramic composite coating is composed of the following components, wherein each component is in mass percentage, WC 24%, TiO 2 17%, Ni 20%, Cr 16%, Co 13%, B 6%, Si 4%.

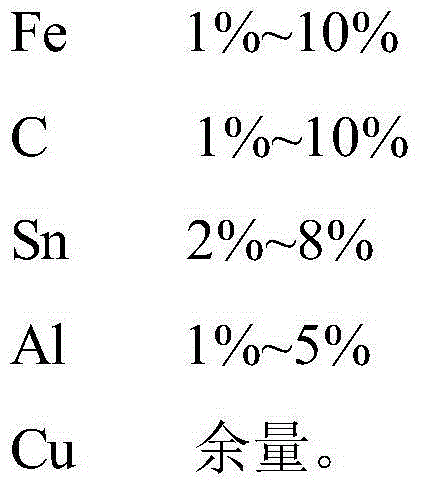

[0038] The copper-based alloy layer is composed of the following components, wherein each component is calculat...

Embodiment 3

[0041]The long-life lute string of the present invention, wherein the lute string is a layered composite structure, the inner core of the layered composite structure is a steel wire twisted rope formed by twisting and forming 9 steel wires, and a supersonic flame is used on the outer surface of each steel wire Spraying technology sprays and prepares a layer of cermet composite coating with a thickness of about 330 μm, and then twists each other to form an inner core. The outer surface of the steel wire inner core is coated with a copper-based alloy intermediate layer, and the outer surface of the intermediate layer is set. Has a nylon exterior.

[0042] Wherein the metal-ceramic composite coating is composed of the following components, wherein each component is in mass percentage, WC 18%, TiO 2 15%, Ni 25%, Cr 19%, Co 13%, B3%, Si 7%.

[0043] The copper-based alloy layer is composed of the following components, wherein each component is calculated by mass percentage: Fe 7%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com