Coal slime drying system and method using electric power plant low-grade steam and solar energy

A low-grade steam and drying system technology, applied in the field of coal slime drying system, can solve the problems of low efficiency of hot blast furnace, uneven drying, uneconomical operation, etc., and achieve good environmental coordination, low operation and maintenance costs, and short drying cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

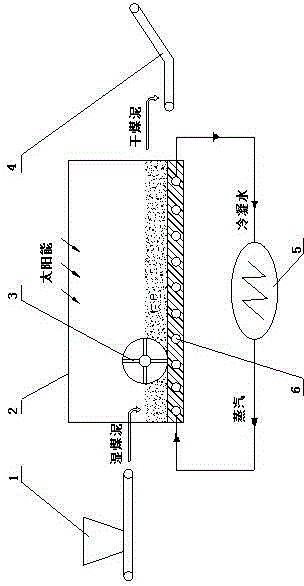

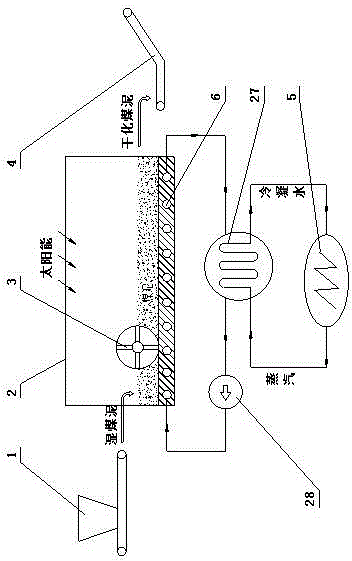

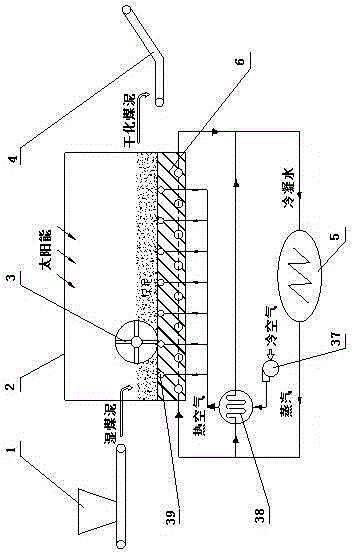

[0024] The present invention proposes a coal slime drying system utilizing low-grade steam and solar energy in power plants, such as figure 1 Shown is the schematic diagram of the first embodiment of the present invention, and the present invention comprises the wet coal slime conveying equipment 1 that is used to transport the wet coal slime to be dried, is used to provide the solar greenhouse 2 of coal slime drying and solar irradiation, uses Coal slime turning machine for spreading, turning, transporting and cutting fine coal slime particles. 3. Dried coal slime conveying equipment for transporting dried coal slime. 4. Used to provide low High-grade steam power plant thermal system 5, floor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com