Fixing device and installation method of prefabricated concrete external wall panel

A technology of external hanging wall panels and prefabricated assembly, which is applied in the direction of walls, building components, buildings, etc., which can solve the problem of affecting the connection strength of prefabricated external hanging wall panels and the main body of the structure, the inability to conveniently adjust the level and height of prefabricated external hanging wall panels, and the inability to prefabricate external hanging wall panels Fixed and other problems, to achieve the effect of simple construction, stable and firm connection, and improved anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The specific process of using the above connection device to install the prefabricated concrete external wall panel is as follows:

[0042] 1) Manufacture the above-mentioned prefabricated external wall panels according to the designed size, and transport them to the project site.

[0043] 2) Complete the hoisting of prefabricated columns, prefabricated beams and laminated panels.

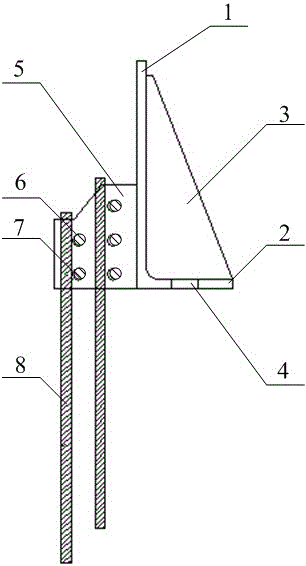

[0044] 3) Fix the panel embedded parts at the set position on the beam.

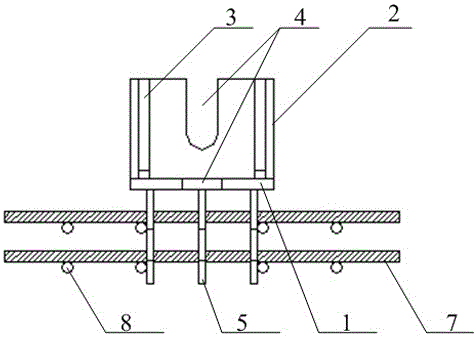

[0045] 4) Use lifting equipment to hoist the prefabricated external wall panels above the beams, and anchor the connecting steel bars of the prefabricated external wall panels into the steel bars of the beams and laminated slabs (that is, floor slabs), such as Figure 11 shown.

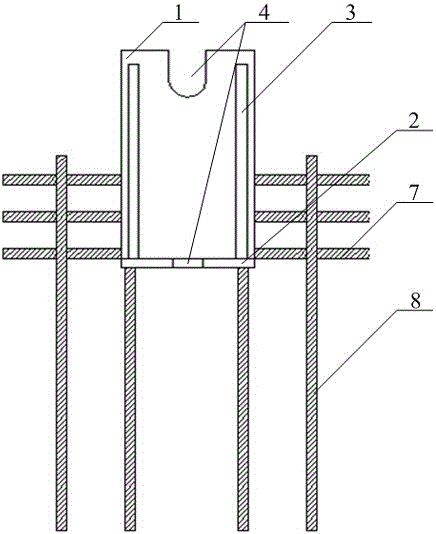

[0046] 5), such as Figure 10 As shown, insert the wall top hanger on the upper part of the prefabricated external wall panel into the embedded part of the panel surface, and snap the tie bolts on the lower part of the prefabricated externa...

Embodiment 2

[0055] The specific process of using the above connection device to install the prefabricated concrete external wall panel is as follows:

[0056] 1) Manufacture the above-mentioned prefabricated external wall panels according to the designed size, and transport them to the project site.

[0057] 2) Complete the hoisting of prefabricated columns, prefabricated beams and laminated slabs; fix the embedded parts on the beams at the set positions, and then pour concrete on the prefabricated beams and laminated slabs. While pouring the concrete, according to the position of the prefabricated external wall panels, reserve post-casting strips of steel bars on the prefabricated beams and composite slabs for the anchoring of the connecting steel bars on the prefabricated external wall panels.

[0058] 3) Use lifting equipment to hoist the prefabricated external wall panels above the beams, and anchor the connecting steel bars of the prefabricated external wall panels into the beam stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com