Operation start method of FCC gasoline hydrogenation catalyst

A gasoline hydrogenation and catalyst technology, applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of large loss of octane number and long start-up period, so as to reduce the loss of octane number and avoid overheating. Risks, the effect of shortening the start-up cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The catalyst used is the same as Comparative Example 1, and its vulcanization conditions and start-up conditions are the same as those of Comparative Example 1. However, the vulcanization process is only for the first-stage catalyst, and the second-stage catalyst is not vulcanized. The temperature of the bed layer in the section is raised to 320°C, and the FCC raw material is directly prepared to be put into it. During the entire oil injection process, the maximum temperature rise of the bed layer was 50°C, and it entered a stable operation state within 36 hours.

[0039] Table 5 Analysis of properties of hydrogenation products

[0040] RON

[0041] Compared with the above-mentioned start-up method, this method has the advantages of low bed temperature rise, small loss of octane number, and fast entering into stable operation period.

Embodiment 2

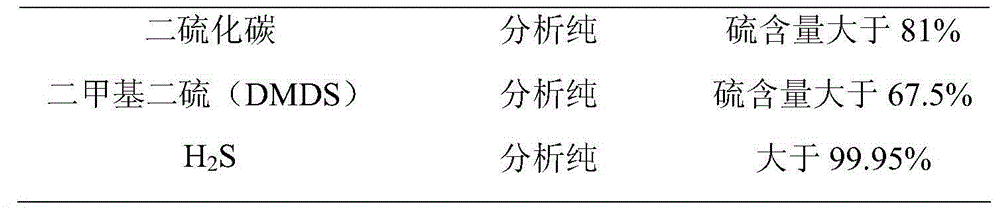

[0043] One stage selective hydrodesulfurization catalyst composition: MoO 3 15wt%, CoO1.5wt%, K 2 O0.8wt%, MgO1.8wt%, and the balance is modified alumina. Second stage octane recovery catalyst: MoO 3 7%, CoO 4%, modified HZSM-5 zeolite 65%, the balance is Al-Ti composite oxide binder, and the start-up conditions are implemented according to Example 1. One-stage vulcanization, two-stage non-sulfurization and direct oil injection, the difference from Example 1 is that the vulcanization method adopts dry vulcanization, and the specific conditions are as follows: the concentration of hydrogen sulfide is between 3000-20000ppm. The vulcanization conditions are common vulcanization conditions in this field, such as: 40°C nitrogen drying for 10 hours, switch hydrogen and increase the temperature of the vulcanizing agent bed to the temperature at which the vulcanizing agent begins to decompose, and increase the temperature to 180 at a rate of 20°C / h. ℃ and keep the temperature for 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com