Blast furnace front refractory casting mold and casting method

A mold and refractory technology, applied in molds, mold auxiliary parts, manufacturing tools, etc., can solve the problems of not improving the efficiency of pouring operations and high use costs, saving preparation time, hoisting and installing simple and convenient, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

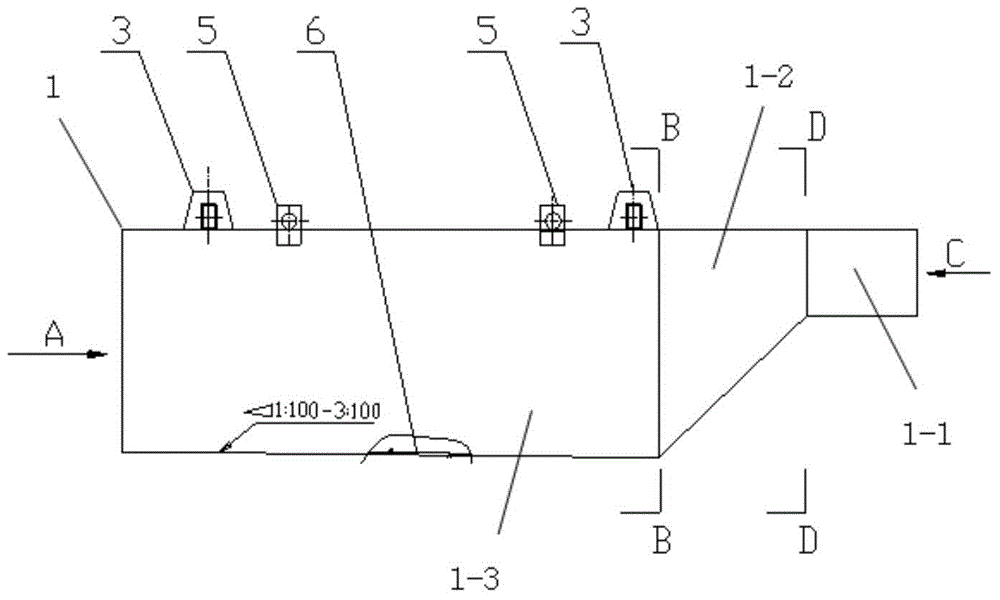

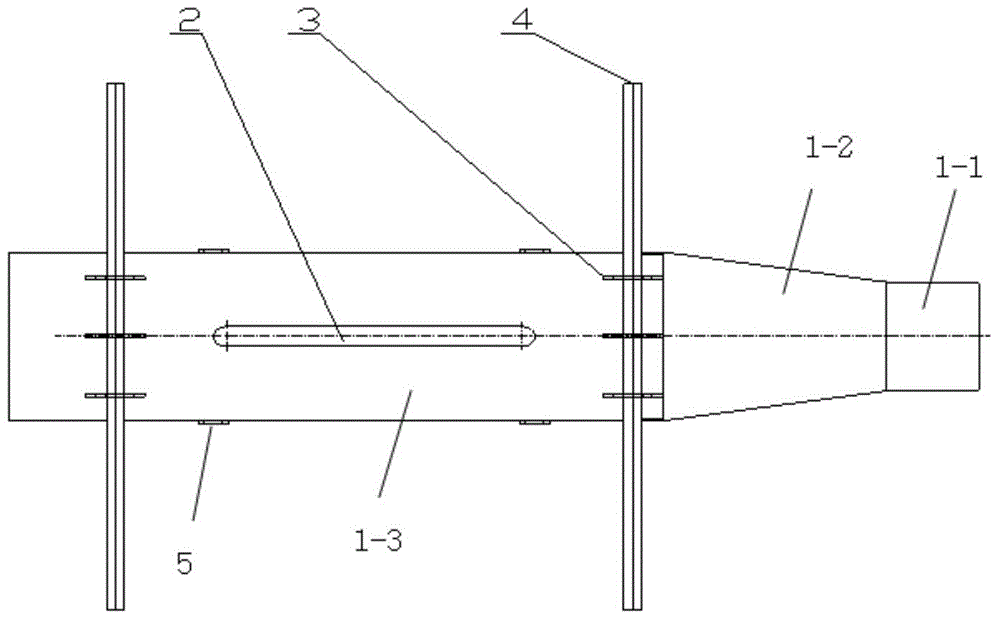

[0076] Ironworks of Laiwu Branch 5 # 1080m 3 Taking the refractory pouring model in front of the blast furnace as an example, the specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0077] Ironworks of Laiwu Branch 5 # 1080m 3 Take the refractory pouring model in front of the blast furnace as an example. The main ditch mold in front of the furnace is 4.3m long, the slightly inclined section is 2.9m, the inclined section is 0.8m, and the iron mouth section is 0.6m. The specific embodiment of the present invention is further described in conjunction with the accompanying drawings.

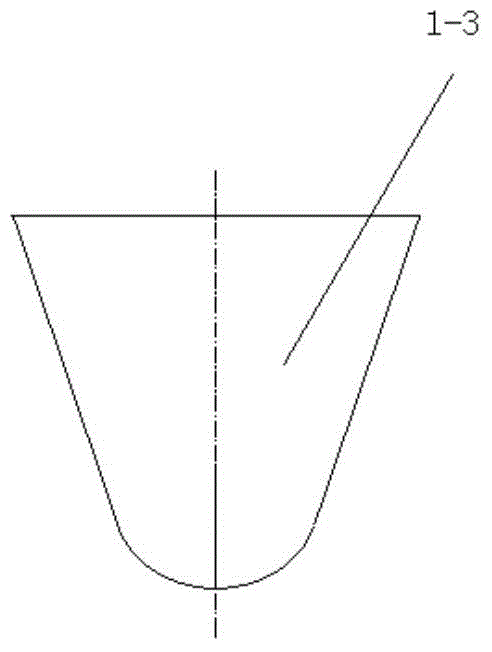

[0078] Adopting the principle of "wedge and segment", design the refractory pouring molds for the tapping channel series in front of the furnace. Use δ=8mm steel plate welding to make the main groove refractory casting mold (the length of the slightly inclined section is 2.9 meters, and the section size is determined by the A dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com