Wood dipping heat treatment pressurization device

A pressurizing device, wood technology, applied in the direction of wood heat treatment, wood treatment, wood impregnation, etc., to achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

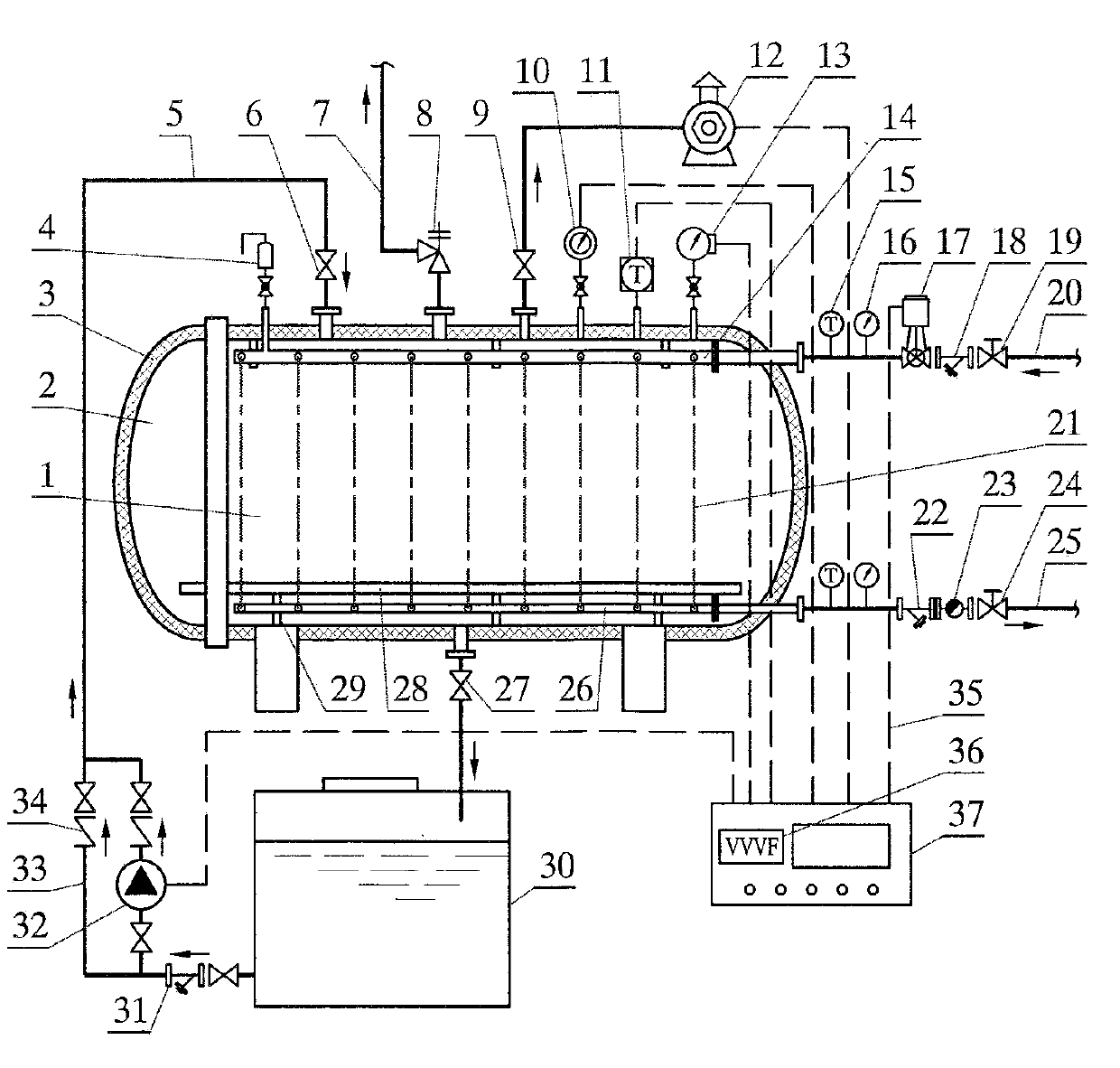

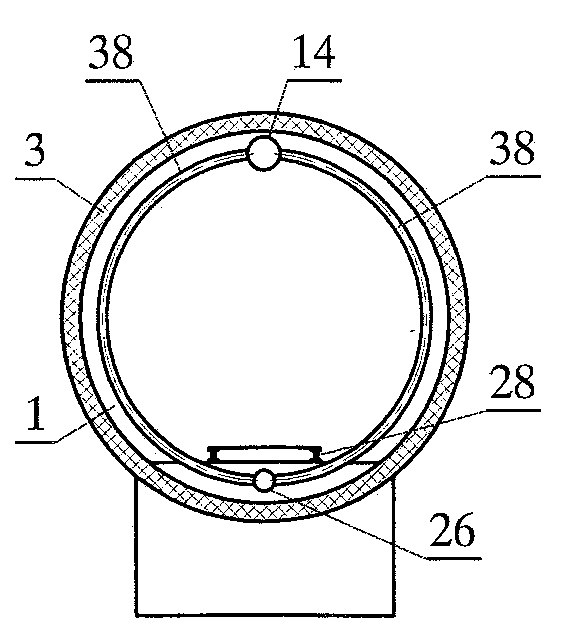

[0013] attached below figure 1 And attached figure 2 The wood impregnation heat treatment pressing device of the present invention will be described in detail below.

[0014] as attached figure 1 As shown in the accompanying drawings, the pressure device for wood impregnation heat treatment of the present invention is mainly composed of a pressure tank body 1, a pressure tank door 2, a vacuum pump 12, a liquid storage tank 30, a pressure pump 32 and a control cabinet 37. The tank body 1 cooperates with the pressure tank door 2 to form a horizontal sealed pressure container. There are heat exchange coils 21 and sliding guide rails 28, and more than 4 groups of heat exchange coils 21 are evenly arranged around the pressure-bearing tank body 1, and each group of heat exchange coils 1 consists of two 180° semicircular heat exchange tubes 38. Both ends of each heat exchange tube 38 are respectively connected to the steam main pipe 14 and the condensed water main pipe 26. The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com