Composite dunaliella salina and preparation method thereof

A technology of compound salt and salt algae powder, applied in food preparation, food science, application, etc., can solve the problems of high cost, unsuitable for large-scale production, complicated process, etc., and achieve low cost, suitable for large-scale production, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The compound salina of the present embodiment does not contain potassium chloride.

[0023] The compound salt algae of this embodiment is made from the following raw materials in proportion by weight: 1000 kg of refined salt, 10 grams of potassium ferrocyanide, 45 grams of potassium iodate, 500 grams of D-sodium erythorbate, and salt algae powder 4 kg, 200 g of β-carotene, 55 kg of purified water;

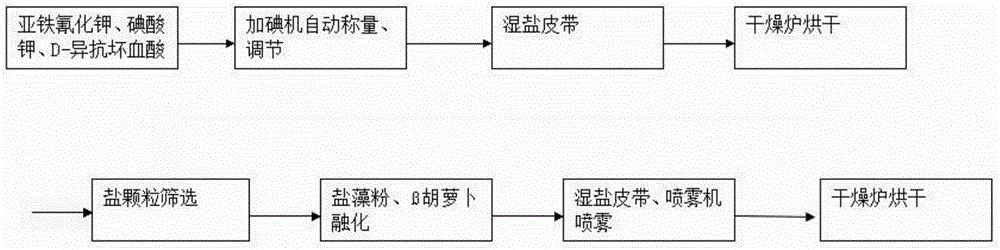

[0024] The process flow is: add 10 grams of potassium ferrocyanide per ton of salt, add 45 grams of potassium iodate per ton of salt, add 500 grams of D-sodium isoascorbate per ton of salt, then add 13kg of pure water, and control the temperature at 60°C , Stir with a mixer for 20 minutes, and make additives after melting. The automatic iodine adding machine weighs the amount of wet salt through an electronic scale, automatically adjusts the amount of additives, and then enters the drying oven for drying. The drying temperature range is 110°C-140°C ℃. Then use a 70-mesh vi...

Embodiment 2

[0026] The compound salina of this embodiment contains potassium chloride.

[0027] The compound salt algae of this embodiment is made from the following raw materials in proportion by weight: 1000 kg of refined salt, 10 grams of potassium ferrocyanide, 45 grams of potassium iodate, 500 grams of D-sodium erythorbate, and salt algae powder 4 kg, 200 g of β-carotene, 300 kg of potassium chloride, 55 kg of purified water;

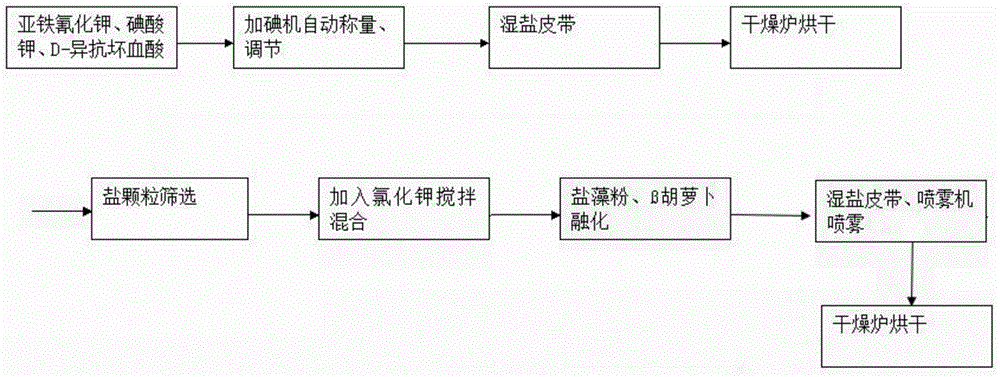

[0028] The process flow is: add 10 grams of potassium ferrocyanide per ton of salt, add 45 grams of potassium iodate per ton of salt, add 500 grams of D-sodium isoascorbate per ton of salt, then add 13kg of pure water, and control the temperature at 60°C , Stir with a mixer for 20 minutes, and make additives after melting. The automatic iodine adding machine weighs the amount of wet salt through an electronic scale, automatically adjusts the amount of additives, and then enters the drying oven for drying. The drying temperature range is 110°C-140°C ℃. Then u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com