Laser ultrasonic detection method and laser ultrasonic detection system for rapidly locating defects

A laser ultrasonic and detection method technology, applied in the direction of optical testing of flaws/defects, measuring devices, and material analysis through optical means, can solve problems such as low detection efficiency, long time consumption, and difficulty in quickly detecting and locating defects. Reduced processing volume, simple operation, and improved speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

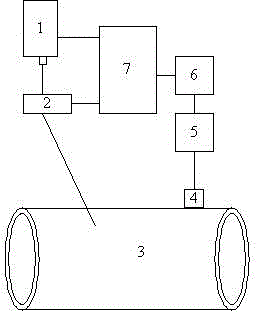

[0041] Select the stainless steel plate of the test piece, the specification is 1000mm×1000mm×3mm, and place the stainless steel plate on the figure 1 In the scan area shown, to figure 1 way to detect.

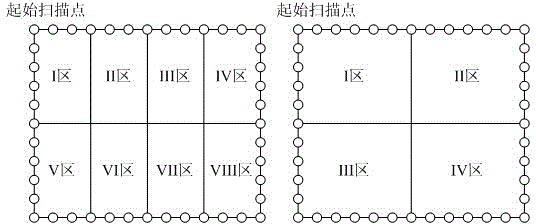

[0042] (1) Adjust the laser 1, apply the laser emitted by the laser 1 to the galvanometer system, and change the scanning route of the laser scanning in the stainless steel plate through the galvanometer scanning system, according to figure 2 The scanning route scans the stainless steel plate point by point, the scanning interval is 1mm, the scanning points are 100×100, and the scanning area is divided into 4 divisions. The ultrasonic signal generated in the stainless steel plate encounters a defect 8 in the stainless steel plate, and the defect acts on the ultrasonic signal, sending "scattered waves" in all directions, and the air-coupled surface wave probe placed in the stainless steel plate receives the generated scattered signal.

[0043] (2) Store the collected ultraso...

Embodiment 2

[0045] Select the aluminum alloy pipe of the test piece, the specification is ¢60mm×4mm, and place the aluminum alloy pipe on the figure 1 In the scan area shown, to image 3 way to detect.

[0046] (1) Adjust the laser 1, apply the laser emitted by the laser 1 to the galvanometer system, and change the scanning route of the laser scanning in the aluminum alloy pipe through the galvanometer scanning system, according to figure 2The scanning route scans the aluminum alloy pipe point by point, the scanning interval is 1mm, the scanning point is 100×100, and the scanning area is divided into 4 areas. The ultrasonic signal generated in the aluminum alloy pipe meets the defect 3 in the aluminum alloy pipe, and the defect acts on the ultrasonic signal, sending "scattered waves" in all directions, and the air-coupled surface wave probe placed in the aluminum alloy pipe receives the generated scattered signal.

[0047] (2) Store the collected ultrasonic signals in the computer, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com