Contour registration method based on machine vision train guide rail contour measurement

A technology of machine vision and contour measurement, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of large errors, inconvenient analysis, statistics and archiving, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the content protected by the present invention is not limited to the following description.

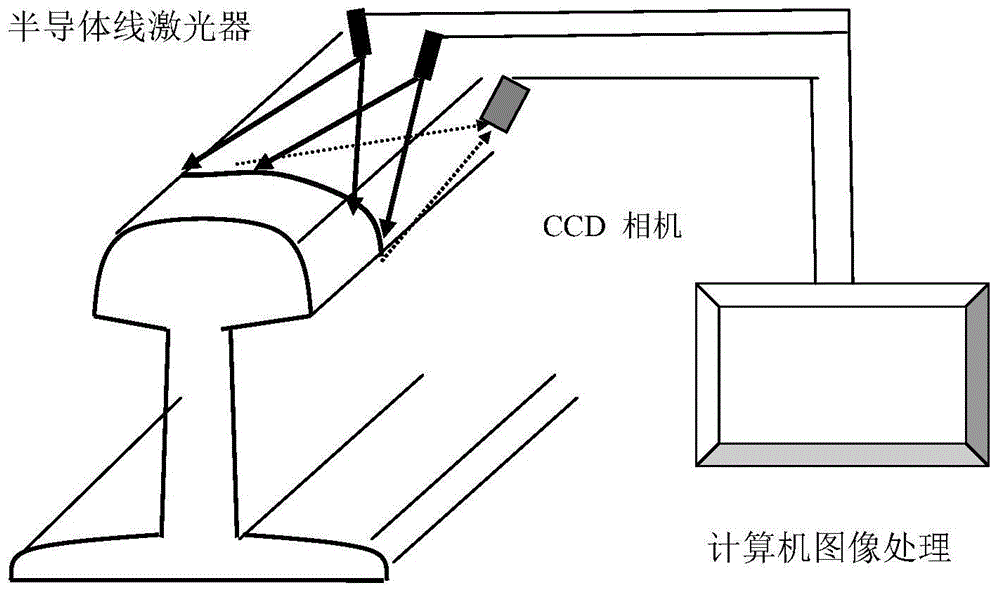

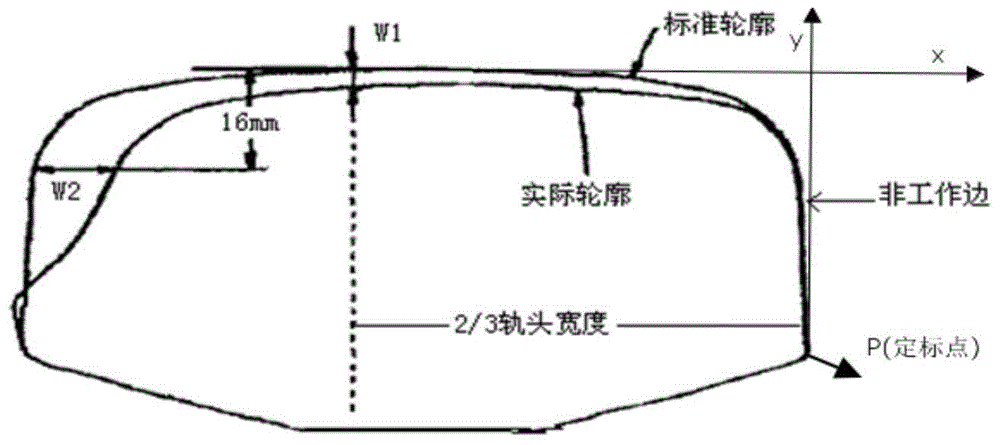

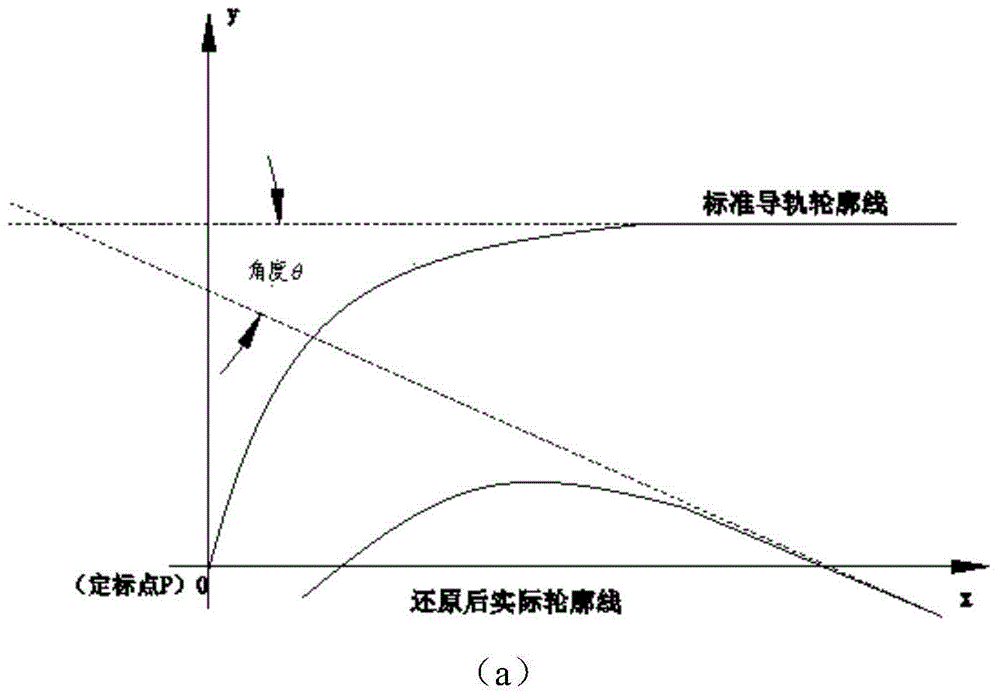

[0058] The principle of contour measurement is as figure 1 As shown, the non-contact measurement is adopted, which can greatly improve the work efficiency of the on-site railway inspection department. The main principle of the measurement is to obtain the profile curve of the rail section through the laser light section method, and use a semiconductor laser to emit laser light. At the same time, the CCD camera collects the laser image and transmits the image information to the processing chip of the computer loaded on the trolley. The wear measurement program performs a series of processing on the collected images to obtain the single pixel curve of the rail section. By matching and correcting the curve image, it is compared with the rail wear poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com