Mechanical sealing end surface deformation measurement system based on binocular vision DIC and measurement method thereof

A mechanical seal, binocular vision technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., to achieve the effect of improving performance and service life, reducing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

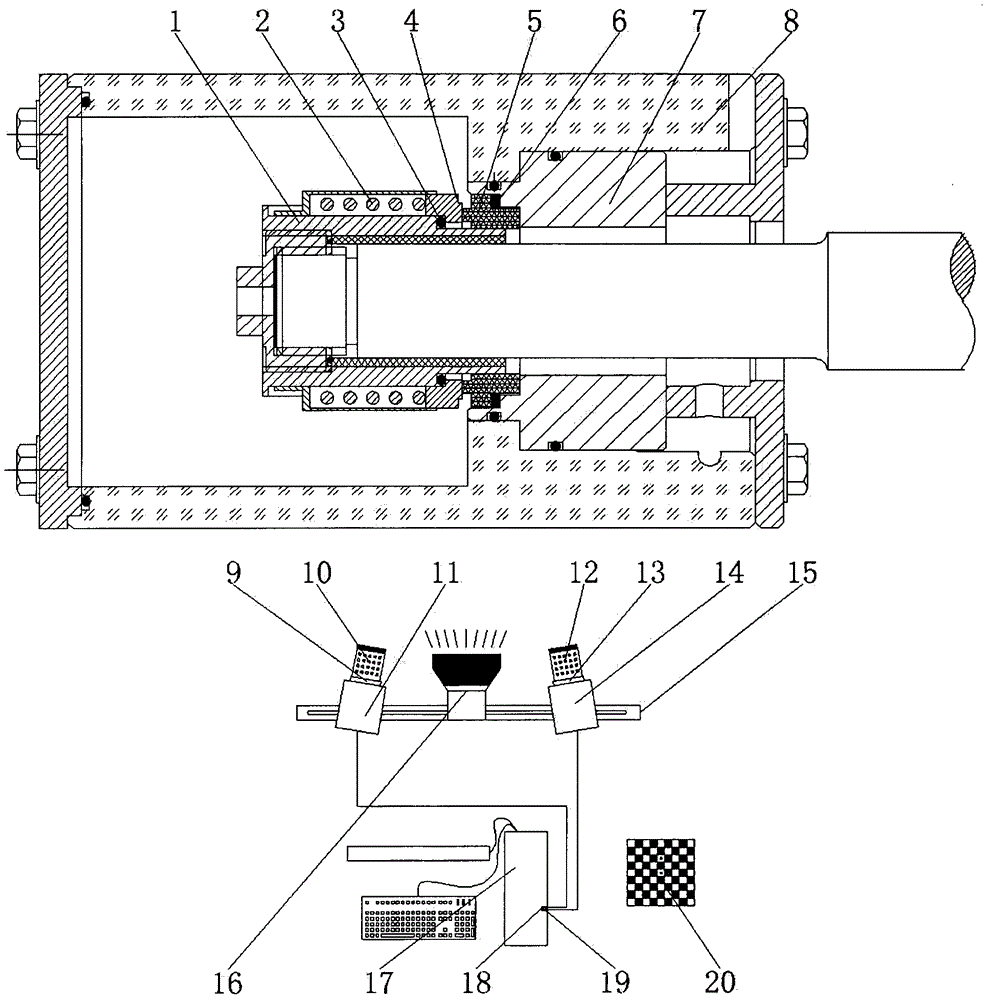

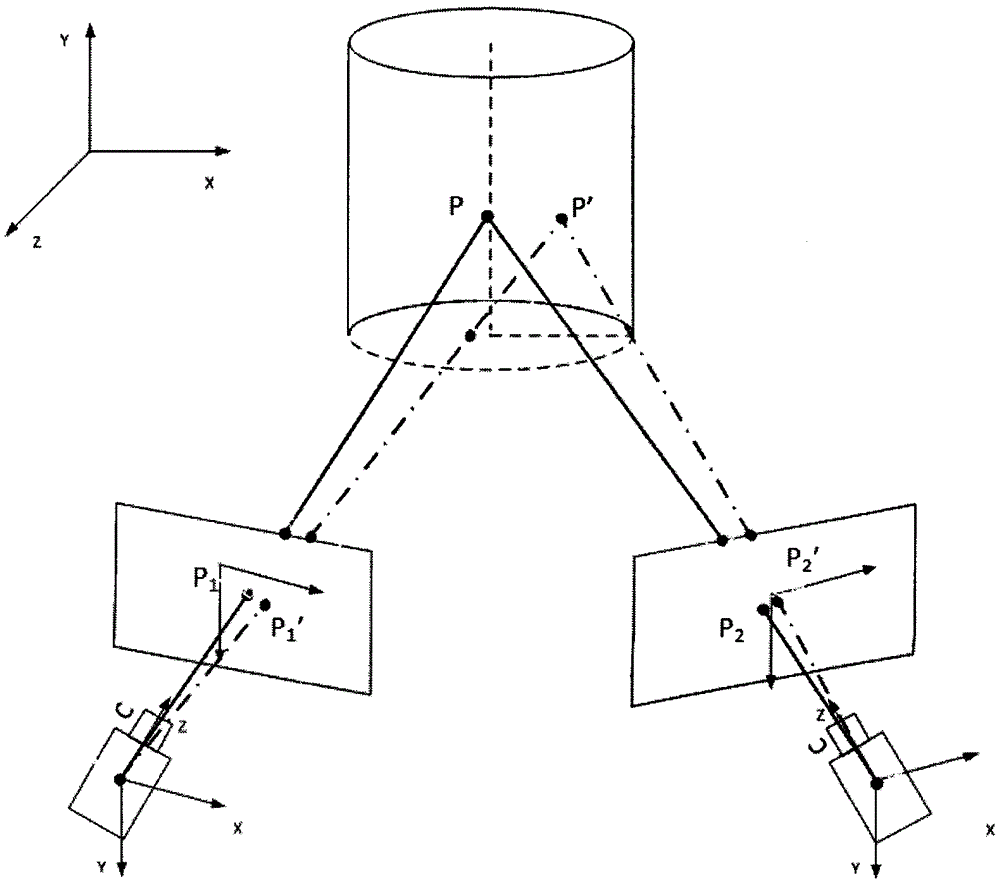

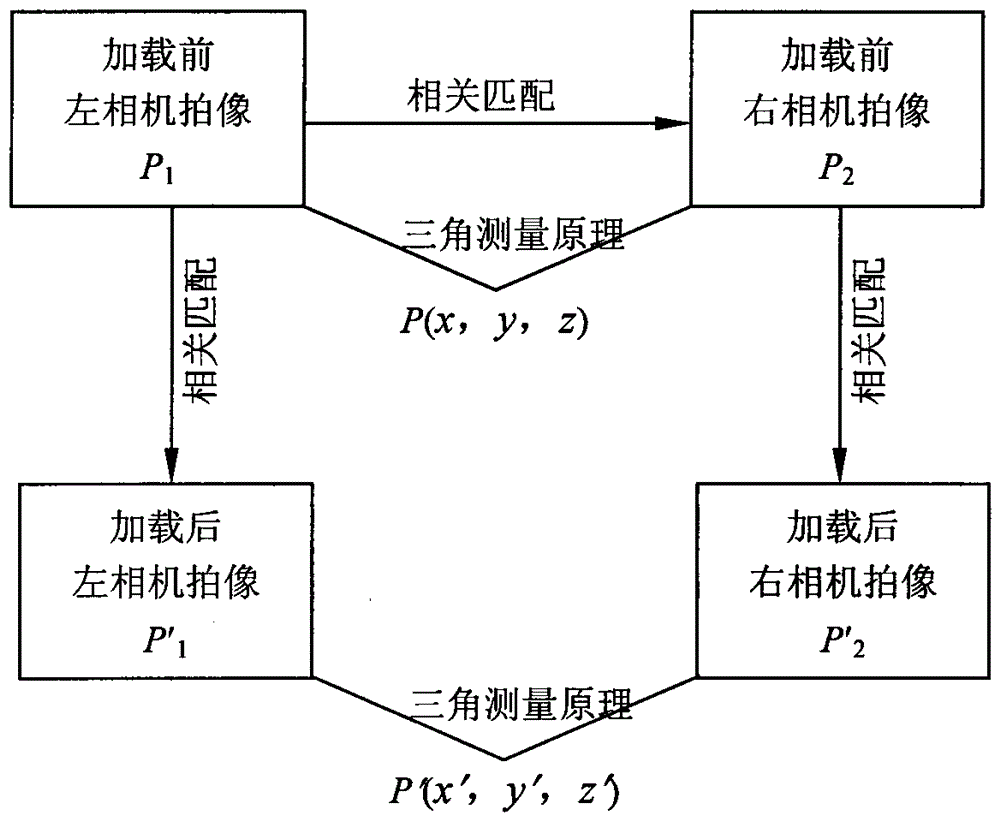

[0040] The measuring system structure of the present invention is as figure 1 As shown, the whole system consists of left high-speed digital camera 9, right high-speed digital camera 13, left lens 10, right lens 12, acquisition card 18,19, light source 16, calibration plate 20, support system (square box 11,14, translation stage 15), composed of computer 17 and mechanical seal test device.

[0041]Its position connection sequence is: the left and right high-speed digital cameras 9,13 are respectively installed in square boxes 11,14 with screws, and there are bolt holes directly below the square boxes 11,14, and the square boxes 11,14 are fixed to the translation platform by bolts 15, the translation platform 15 is installed on the guide rail on the tripod; adjust the angle and distance between the left and right high-speed digital cameras 9 and 13 by adjusting the bolts below the square boxes 11 and 14; Adjust the height and pitch angle of left and right high-speed digital ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com