Method for preparing medical bone gelatin by biological enzyme method

A biological enzyme method, bone gelatin technology, applied in fermentation and other directions, can solve the problems of high production cost, difficult to control enzymatic hydrolysis process, collagen fiber peptide chain destruction, etc., to achieve clean production, high molecular weight, strong freezing force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

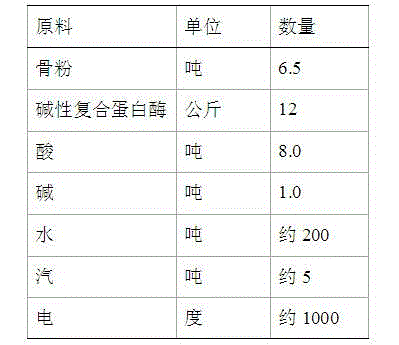

Embodiment 1

[0029] An example of a production line with a daily production of 1 ton of gelatin: Take pig bones, beef bones and other animal bones and crush them to 30-150 mesh, mix the above 4 tons of bone powder with water at a mass ratio of 1:5, stir, and adjust to a bone powder suspension, input to 30m 3 in the pickling tank. Take hydrochloric acid with a concentration of 10%, and add it to the bone powder suspension in a slow feeding method to remove minerals in the bone powder, specifically:

[0030] Add water with a weight ratio of 1:5 to the bone meal, start stirring, and add 10% hydrochloric acid in a slow feeding manner. After each pickling, use a turbo centrifuge to clean the bone meal, and then add water at a ratio of 1:5. into a suspension, the pickling water temperature is 18 ℃.

[0031] Pickling for the first time: pH value is controlled at 3.5-4.0, pickling for about 2 hours after cleaning;

[0032] The second pickling: the pH value is controlled at 3.5-4.0, and it is wa...

Embodiment 2

[0042] An example of a production line with a daily production of 1 ton of gelatin: Take pig bones, beef bones and other animal bones and crush them to 30-150 mesh, mix the above 4 tons of bone powder with water at a mass ratio of 1:5, stir, and adjust to a bone powder suspension, input to 30m 3 in the pickling tank. Take hydrochloric acid with a concentration of 10%, and add it to the bone powder suspension in a slow feeding method to remove minerals in the bone powder, specifically:

[0043]Add water with a weight ratio of 1:5 to the bone meal, start stirring, and add 10% hydrochloric acid in a slow feeding manner. After each pickling, use a turbo centrifuge to clean the bone meal, and then add water at a ratio of 1:5. into a suspension, the pickling water temperature is 18 ℃.

[0044] Pickling for the first time: pH value is controlled at 3.5-4.0, pickling for about 2 hours after cleaning;

[0045] The second pickling: the pH value is controlled at 3.5-4.0, and it is was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com