Conductive glue, preparation method thereof and circuit board

A technology of conductive adhesive and conductive particles, applied in conductive adhesives, printed circuit parts, adhesives, etc., can solve the problem of high cost, and achieve the effect of improving solderability and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] At the same time, the present invention also provides a method for preparing the above-mentioned conductive glue, which includes the following steps: taking the conductive particles for standby; mixing the resin matrix with the conductive particles to obtain the precursor of the conductive glue; conducting the conductive glue precursor Cured to form a conductive adhesive. In this preparation method, a conductive adhesive with better performance can be obtained through a simple mixing step and then curing.

[0034] In a more preferred embodiment of the present invention, when the conductive adhesive also includes a diluent and / or a coupling agent, the above step S2 includes: S21, performing a first Mixing for the first time to obtain the first mixture; S22, mixing the first mixture with the conductive particles for the second time to obtain the conductive adhesive precursor. By step-by-step mixing, the mixed conductive particles can be more uniformly mixed with the resi...

Embodiment 1

[0043] Take 50g 300-mesh copper powder and 50g tin powder, mix them evenly to obtain mixed metal powder, set aside;

[0044] 10 g of epoxy resin E-51 with an epoxy equivalent of 100 and 4 g of ethylene glycol ether were mechanically stirred for 15 min and mixed uniformly to obtain the first mixture;

[0045] Then add 100g mixed metal powder to the above-mentioned first mixture, fully mix in the banbury mixer, obtain the conductive glue precursor;

[0046] Add 3 g of a polyamide curing agent with a molecular weight of 800 to the conductive adhesive precursor and cure at 150° C. for 40 minutes to prepare the conductive adhesive.

Embodiment 2 to Embodiment 12

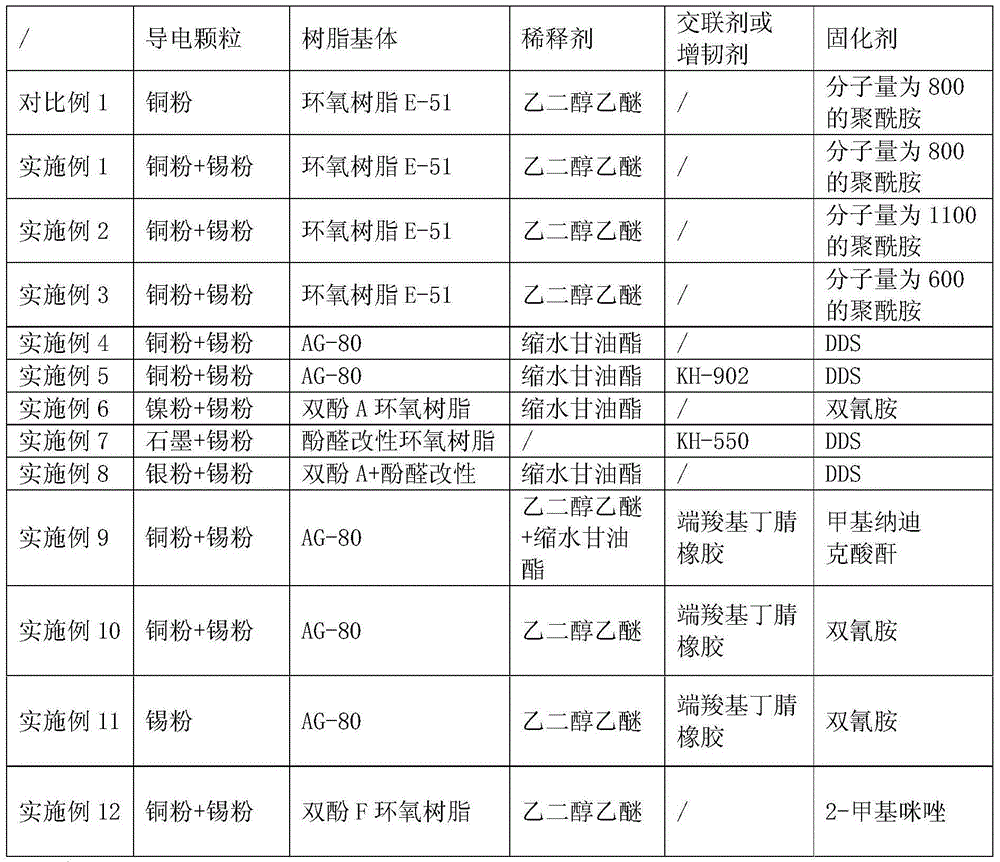

[0048] According to the steps identical with embodiment 1, carry out the preparation of conductive adhesive with the raw material shown in table 1 and the preparation parameter shown in table 2, obtain the conductive adhesive of each embodiment, and the performance of the conductive adhesive of each embodiment The test was carried out, and the test results are shown in Table 3.

[0049] Table 1: (raw materials)

[0050]

[0051] Table 2:

[0052]

[0053]

[0054] table 3:

[0055]

[0056] It can be seen from the above Comparative Example 1 and Examples 1-12 that the resistance of the conductive adhesive prepared by the preparation method of the present invention is much smaller than that of Comparative Example 1, which greatly improves the conductivity of the conductive adhesive. Moreover, the shear strength of the conductive adhesive of the present invention is much larger than that of Comparative Example 1, indicating that the conductive adhesive of the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com