Yellow outer rubber for bus air conditioner rubber pipes and preparation method thereof

A technology for buses and air conditioners, which is applied in the field of materials, can solve the problems of air conditioner pipe bubbling, low physical properties, and liquid leakage, and achieve the effects of good adhesion, improved permeability, and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

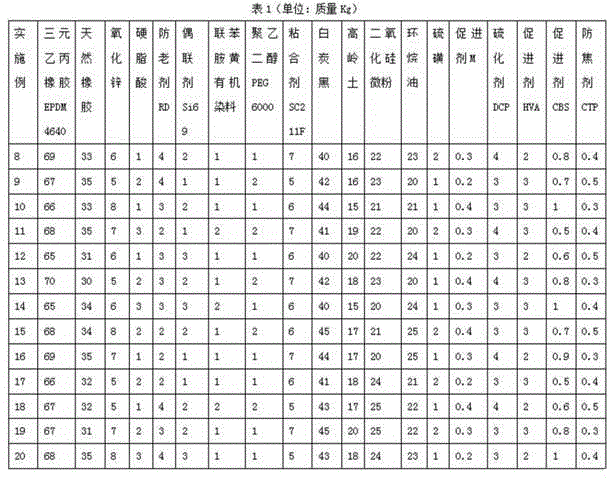

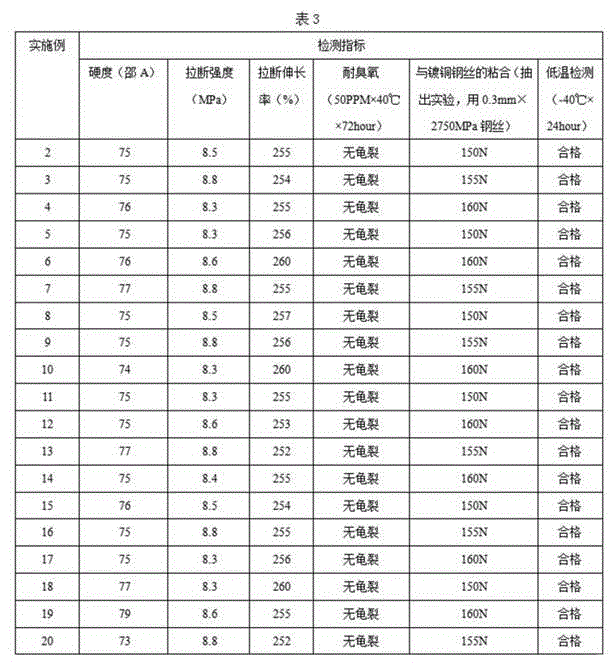

[0025] The yellow outer rubber used for the air-conditioning rubber hose of the bus transporting R134a refrigerant is composed of the following raw materials in parts by weight: EPDM4640 65-70, natural rubber 30-35, zinc oxide 5-8, stearic acid 1 -3. Antiaging agent RD2-4, coupling agent Si69 1-3, benzidine yellow organic pigment 1-2, polyethylene glycol PEG6000 1-2, adhesive SC211F5-7, white carbon black 40-45, kaolin 15-20, silica powder 20-25, naphthenic oil 20-25, sulfur 1-2, accelerator M 0.2-0.4, vulcanizing agent DCP3-4, accelerator HVA-2 2-3, accelerator CBS 0.5 -1. Anti-scorch agent CTP0.3-0.5.

[0026] The preparation method of the yellow outer layer rubber for the bus air-conditioning rubber hose that transports R134a refrigerant comprises the plasticizing process and mixing process of EPDM rubber and natural rubber blending rubber, and the EPDM rubber and natural rubber are blended Plastic refining process

[0027] The plasticizing process is divided into three s...

Embodiment 2

[0041] The yellow outer rubber used for the air-conditioning rubber hose of the bus transporting R134a refrigerant is composed of the following raw materials in parts by weight: EPDM4640 70kg, natural rubber 30kg, zinc oxide 5kg, stearic acid 1kg, anti-aging agent RD2 kg, coupling agent Si691 kg, benzidine yellow organic pigment 1.2 kg, polyethylene glycol PEG6000 1.5 kg, binder SC211F5 kg, white carbon black 45 kg, kaolin 20 kg, silica powder 20 kg, ring 25 kg of paraffin oil, 1 kg of sulfur, 0.3 kg of accelerator M, 3.2 kg of vulcanizing agent DCP, 22 kg of accelerator HVA-22 kg, 0.8 kg of accelerator CBS, and 0.5 kg of anti-scorch agent CTP.

[0042] The preparation method of the yellow outer rubber for the air-conditioning rubber hose of the bus transporting R134a refrigerant, including the plasticizing process and the mixing process of the blended rubber of EPDM rubber and natural rubber,

[0043] The plasticizing process of the EPDM rubber and natural rubber blend,

[0...

Embodiment 3

[0059] The yellow outer rubber used for the air-conditioning rubber hose of buses transporting R134a refrigerant is composed of the following raw materials in parts by weight: EPDM4640 67kg, natural rubber 34 kg, zinc oxide 6 kg, stearic acid 3 kg, anti-aging agent RD4 kg, coupling agent Si69 3 kg, benzidine yellow organic pigment 2 kg, polyethylene glycol PEG6000 1 kg, adhesive SC211F5 kg, white carbon black 43 kg, kaolin 19 kg, silica powder 24 kg, cyclo 23 kg of paraffin oil, 2 kg of sulfur, 0.2 kg of accelerator M, 4 kg of vulcanizing agent DCP, 3 kg of accelerator HVA-2, 1 kg of accelerator CBS, and 0.5 kg of anti-scorch agent CTP.

[0060] The preparation method of the yellow outer rubber for the air-conditioning rubber hose of the bus transporting R134a refrigerant, including the plasticizing process and the mixing process of the blended rubber of EPDM rubber and natural rubber,

[0061] The plasticizing process of the EPDM rubber and natural rubber blend,

[0062] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com