Energy-saving preparation method of low-ingredient xylo-oligosaccharide powder

A technology for xylo-oligosaccharides and wood oligosaccharides, which is applied in the preparation of oligosaccharides and sugar derivatives, chemical instruments and methods, etc. Use effect and scope and other issues, to achieve the effect of facilitating operation and process adjustment, reducing the production of pigments, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the preparation of low-component xylo-oligosaccharide powder

[0028] (1) The corncobs are cyclically cleaned by hydrochloric acid with a mass concentration of 0.2% at 70°C, and the cleaning solution is recycled for use; the cleaned materials and production water are slurried at a ratio of 1:8 (g / ml), and after being stirred evenly, the Pretreatment at 160°C for 3 hours to obtain a feed solution rich in soluble xylan hemicellulose fragments; add 40 IU of xylanase to the feed solution according to the dry weight of the material for enzymolysis, and adjust the pH value of the feed solution to 4 , incubating at 60°C for 12 hours; the enzymatic solution was separated and purified to obtain a xylooligosaccharide solution with a mass concentration of 4%, and the xylooligosaccharide component was about 75%;

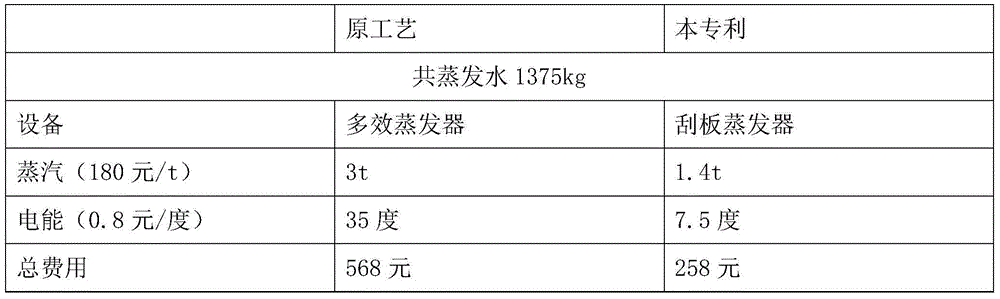

[0029] (2) The xylo-oligosaccharide liquid of step (1) is concentrated to a concentration of 20% xylo-oligosaccharide liquid through a three-effect evaporat...

Embodiment 2

[0040]Embodiment 2: the preparation of low-component xylo-oligosaccharide powder

[0041] (1) The corn stalks are cyclically cleaned with 0.5% sodium hydroxide at 70°C, and the cleaning solution is recovered and recycled; the cleaned materials and production water are mixed at a ratio of 1:10 (g / ml), and stirred evenly Afterwards, the pressure is 3.0MPa, and the time is 60s high-pressure instantaneous blasting treatment to obtain a feed liquid rich in soluble xylan hemicellulose fragments; add 80IU xylanase to the feed liquid according to the dry weight of the material for enzymatic hydrolysis , adjust the pH value of the feed solution to 8, and keep it warm at 45°C for 24 hours; the enzymolysis solution is separated and purified to obtain a xylooligosaccharide liquid with a mass concentration of 5%; the xylooligosaccharide component is about 70%.

[0042] (2) Concentrate the sugar solution in step (1) to a concentration of 20% xylooligosaccharide liquid through a three-effect...

Embodiment 3

[0053] Embodiment 3: the preparation of low-component xylo-oligosaccharide powder

[0054] (1) Cottonseed hulls are cyclically cleaned with hydrochloric acid with a mass concentration of 0.9% at 70°C, and the cleaning solution is recovered and recycled; the cleaned materials and production water are mixed at a ratio of 1:10 (g / ml), and after being stirred evenly, the The pressure is 2.0MPa, and the time is 120s high-pressure instantaneous blasting treatment to obtain a feed liquid rich in hemicellulose fragments of soluble xylan; add 20IU xylanase to the feed liquid according to the dry mass of the material for enzymolysis, adjust The pH value of the feed solution is 6, and it is kept at 85°C for 4 hours. After the enzymolysis solution is separated and purified, a xylooligosaccharide liquid with a mass concentration of 4% is obtained, and the xylooligosaccharide component is about 73%;

[0055] (2) The sugar solution in step (1) is concentrated to a xylooligosaccharide solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com