Fluoride-free preparation method of titanium dioxide of similar graphene structure

A titanium dioxide and graphene technology, applied in the field of new energy materials and nanomaterials, can solve the problem of high carbonization temperature, and achieve the effects of large size area, high yield and controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment includes the following steps:

[0027] 1) Add 5.25g TTIP to 3.75g concentrated hydrochloric acid with a mass fraction of 37%, and stir for 15min;

[0028] 2) Add 1g of Pluronic P123 to 15g of ethanol and stir for 30min; then add it to the mixture obtained in step 1 and stir for 30min;

[0029] 3) Take 20mL of the mixture obtained in step 2, add it to a beaker filled with 150mL of ethylene glycol, and stir for 30min;

[0030] 4) Pour the mixed solution obtained in the above step 3 into the reaction kettle, heat-treat at 150°C, and keep it warm for 12 hours. The obtained product is centrifuged, washed repeatedly with deionized water and absolute ethanol for 3 times, and dried in a drying oven at 60°C to obtain Titanium dioxide with a graphene-like structure.

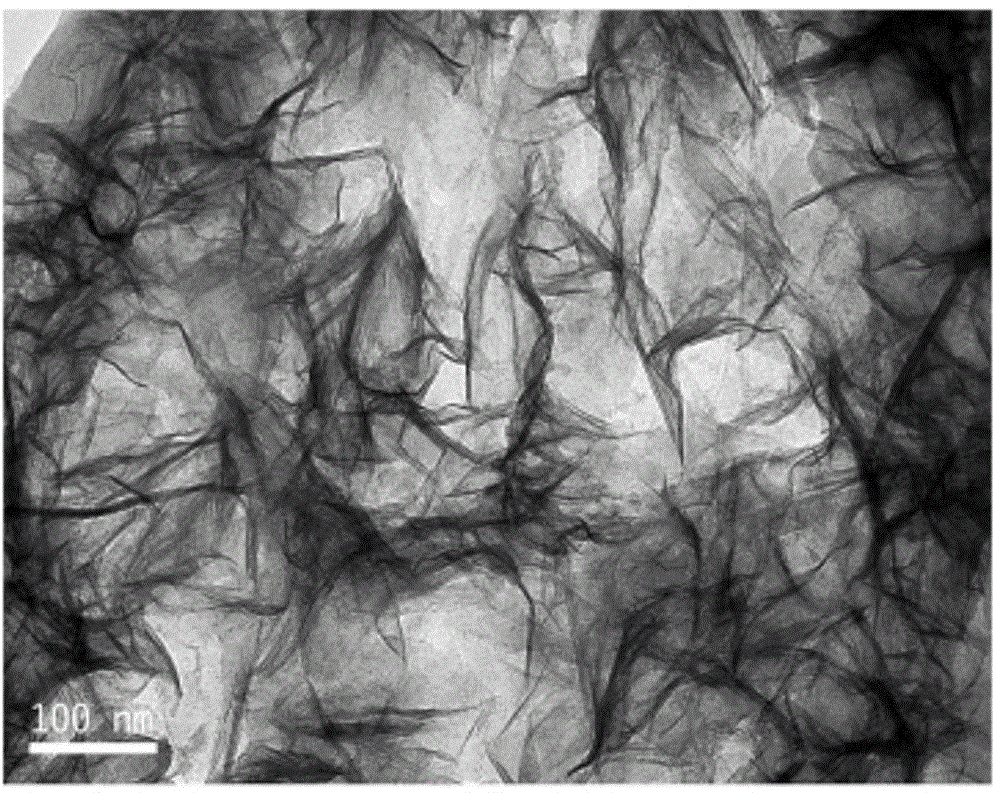

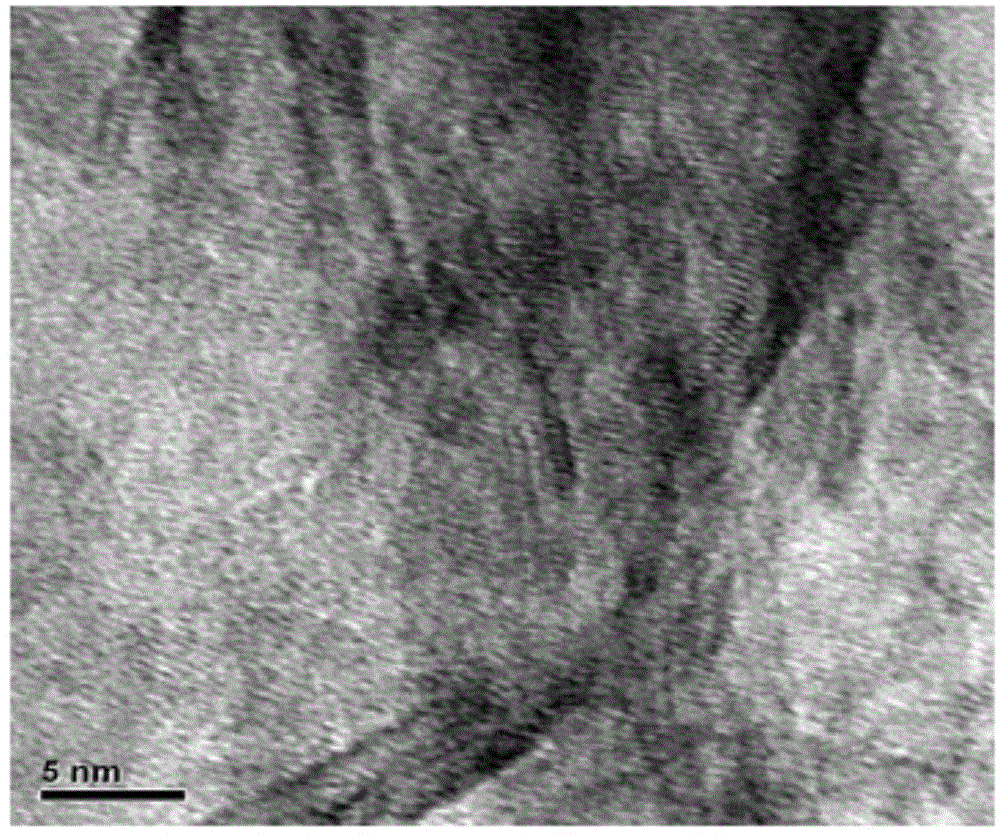

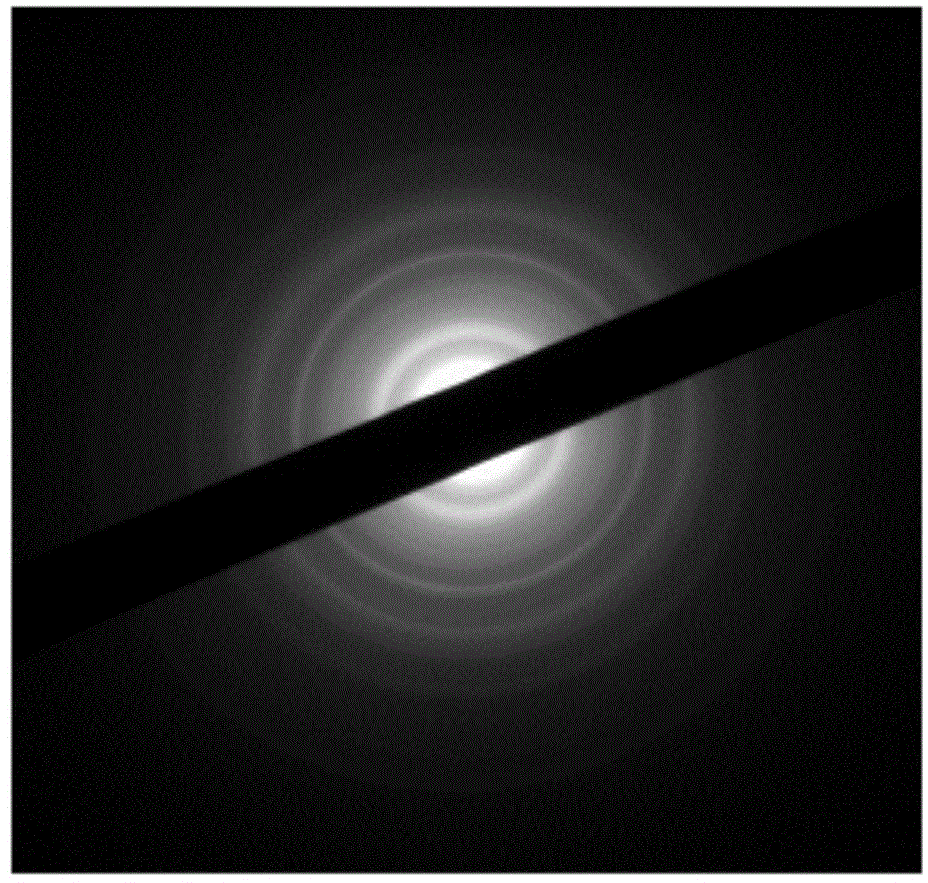

[0031] Such as Figure 1 ~ Figure 3 As shown, the effect of the titanium dioxide prepared in this embodiment is: the prepared titanium dioxide has a graphene ultra-thin nanosheet structure, the si...

Embodiment 2

[0033] This embodiment includes the following steps:

[0034] 1) Add 5.25g TTIP to 3.75g concentrated hydrochloric acid with a mass fraction of 37%, and stir for 15min;

[0035] 2) Add 0.5g of Pluronic P123 to 15g of ethanol, stir for 30min; then add to the mixture obtained in step 1 and stir for 30min;

[0036] 3) Take 20mL of the mixture obtained in step 2, add it to a beaker filled with 50mL of ethylene glycol, and stir for 30min;

[0037] 4) Pour the above solution into the reaction kettle, heat-treat at 100°C, and keep it warm for 12 hours. The obtained product is centrifuged, washed repeatedly with deionized water and absolute ethanol for 3 times, and dried in a drying oven at 60°C to obtain graphene-like Structure of titanium dioxide.

Embodiment 3

[0039] This embodiment includes the following steps:

[0040] 1) Add 5.25g TTIP to 3.75g concentrated hydrochloric acid with a mass fraction of 37%, and stir for 15min;

[0041] 2) Add 1.5g of Pluronic P123 to 15g of ethanol, stir for 30min; then add to the mixture obtained in step 1 and stir for 30min;

[0042] 3) Take 20mL of the mixture obtained in step 2, add it to a beaker filled with 100mL of ethylene glycol, and stir for 30min;

[0043] 4) Pour the above solution into a reaction kettle, heat-treat at 200°C, and keep warm for 12 hours. The obtained product is centrifuged, washed repeatedly with deionized water and absolute ethanol for 3 times, and dried in a drying oven at 60°C to obtain a graphene-like Structure of titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com