Active carbon preparation method based on catkin

A kind of activated carbon preparation and activated carbon technology, which is applied in the field of catkin-based activated carbon preparation, can solve the problems of small specific surface area, lack of artificial regulation of target material pore structure, etc., and achieve large specific surface area, high rate performance and good capacitance characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

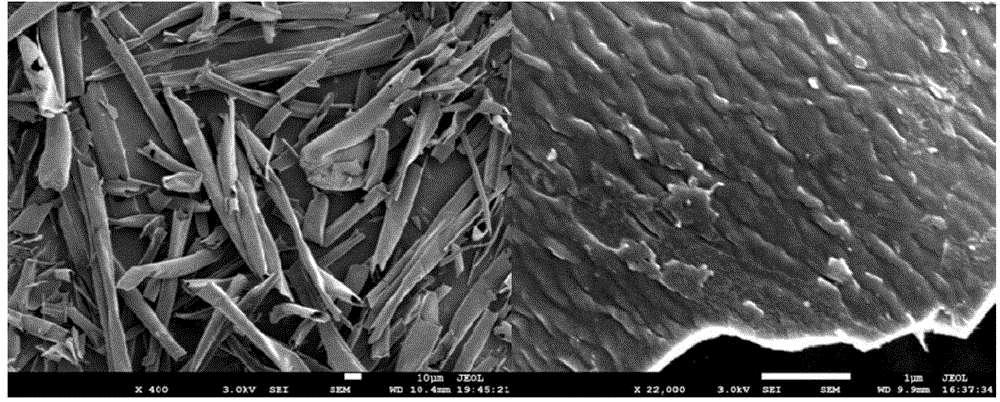

[0022] Disperse 10 g of catkins in 300 ml of anhydrous ethanol solution by ultrasound, and then filter to obtain pure catkins; place the wet catkins in a carbonization furnace in turn, under an argon atmosphere, at 400 o Under the temperature of C, carbonize for 3 h to obtain carbonized material; then the carbonized catkins and potassium hydroxide are dispersed in 50 wt% ethanol aqueous solution according to the mass ratio of 1:1, then dried, and then placed in the activation furnace , under nitrogen atmosphere, at 800 o C for 20 min at a constant temperature, naturally cooled to room temperature to obtain an activated carbon sample; finally, the activated activated carbon sample was acid-washed and washed in turn until the filtrate was clear and the pH reached 7; o C drying treatment, the preparation specific surface area is 1020 m 2 / g, activated carbon with a nitrogen content of 3.12wt%.

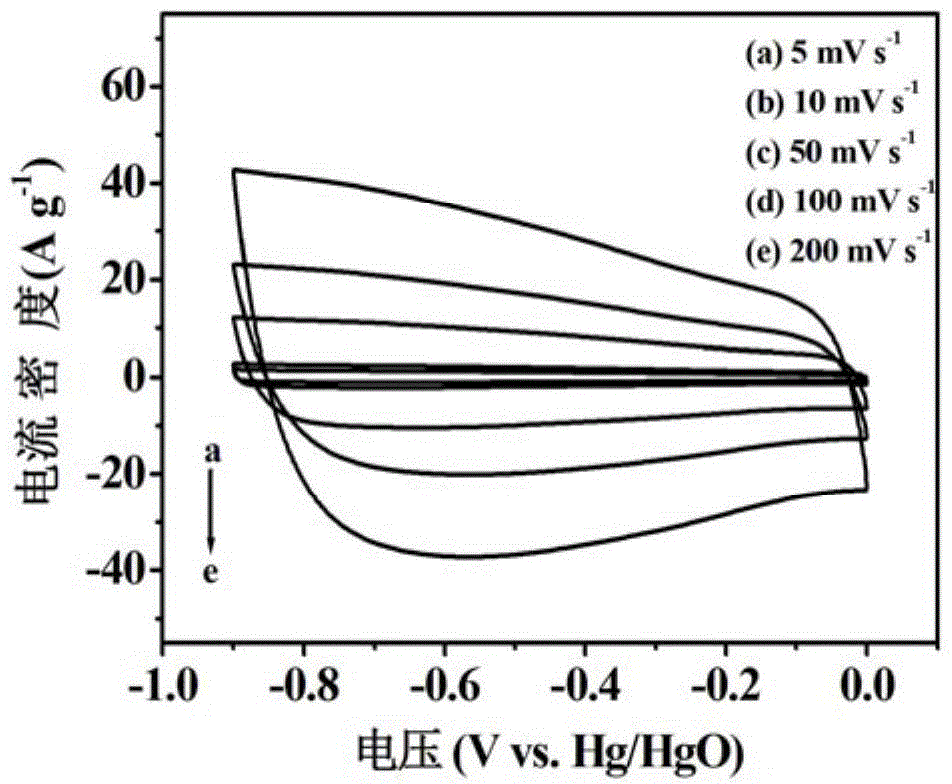

[0023] Add the prepared activated carbon, acetylene black, and polytetrafluoroethyl...

Embodiment 2

[0025] Disperse 10 g of catkins in 600 ml of anhydrous ethanol solution by ultrasound, and then filter to obtain pure catkins; put the wet catkins in a carbonization furnace in turn, under nitrogen atmosphere, at 500 o C, carbonized for 1.5 h to obtain carbonized material; then the carbonized catkins and potassium hydroxide were dispersed in 50 wt% ethanol aqueous solution at a mass ratio of 1:3, dried, and then placed in an activation furnace , under nitrogen atmosphere, at 600 o C for 50 min at a constant temperature, and naturally cooled to room temperature to obtain an activated carbon sample; finally, the activated activated carbon sample was washed with acid and water in sequence until the filtrate was clear and the pH reached 7; o C drying treatment, the preparation specific surface area is 1340m 2 / g, activated carbon with a nitrogen content of 4.92wt%.

[0026] The method for preparing the electrode is the same as that in Example 1. After testing, when the current d...

Embodiment 3

[0028] Disperse 10 g of catkins in 900 ml of anhydrous ethanol solution by ultrasound, and then filter to obtain pure catkins; place the wet catkins in a carbonization furnace in turn, under an argon atmosphere, at 1000 o Under the temperature of C, carbonize for 1 h to obtain carbonized material; then the carbonized catkins and potassium hydroxide are dispersed in 50 wt% ethanol aqueous solution according to the mass ratio of 1:4, and then dried, and then placed in the activation furnace , under argon atmosphere, at 600 o C for 70 min at a constant temperature, naturally cooled to room temperature to obtain activated carbon samples; finally, the activated activated carbon samples were washed with acid and water in sequence until the filtrate was clear and the pH reached 7; o C drying treatment, the preparation specific surface area is 1540 m 2 / g, activated carbon with a nitrogen content of 2.56 wt%.

[0029] The method for preparing the electrode is the same as that in Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com