3D printer wire feeding device

A technology of 3D printer and wire feeding device, applied in the direction of additive processing, etc., can solve the problems of long manual operation time, low efficiency, inconvenient, etc., and achieve the effect of simplifying wire feeding operation and improving wire feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

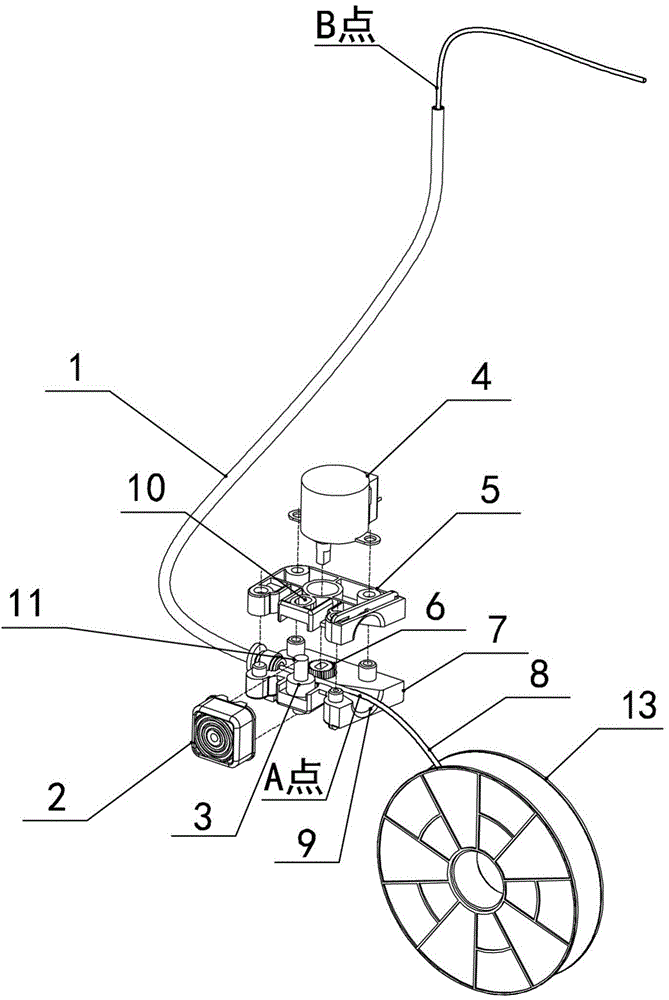

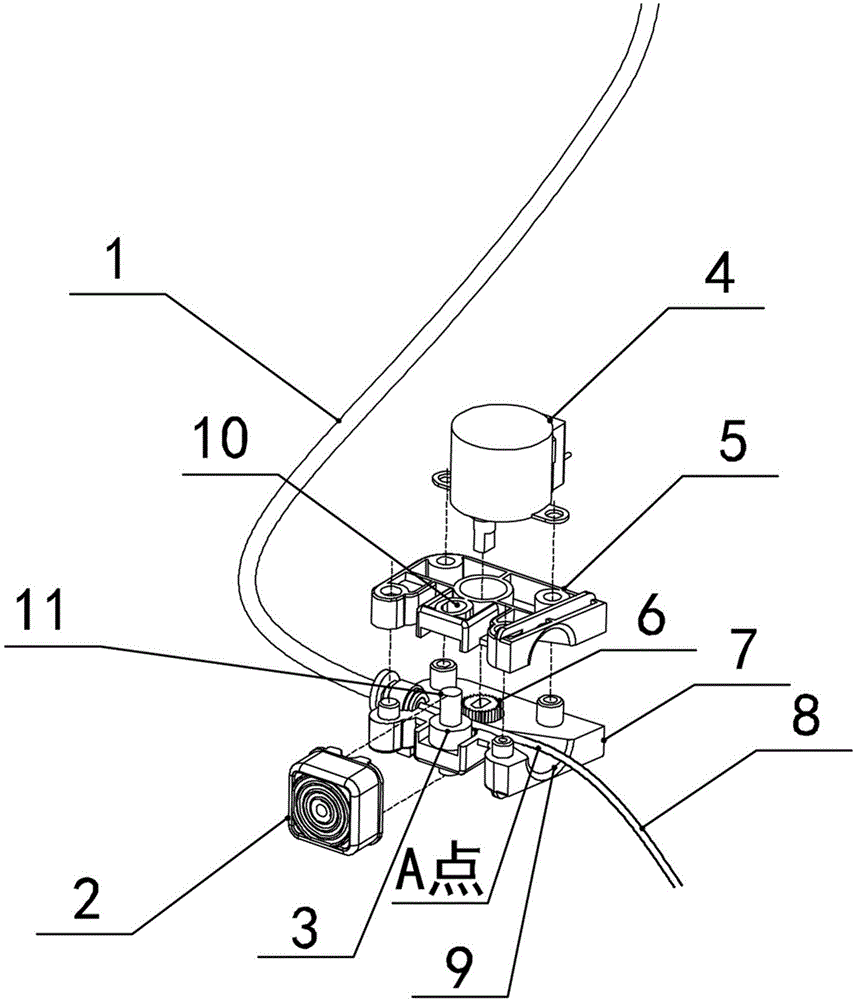

[0022] Example 1: The assembly drawing of Example 1 is as figure 1 As shown, the final assembly drawing is as Figure 4 As shown, figure 1 The partial enlarged view of figure 2 As shown, it includes a guide wire tube 1, a button 2, a sliding bearing 3, a motor 4, a gear 6, a fixed bracket, and a wire feeding port 9.

[0023] The fixing bracket includes an upper fixing bracket 5 and a lower fixing bracket 7, and the upper fixing bracket 5 and the lower fixing bracket 7 are combined to form a wire feeding cavity.

[0024] The fixed bracket is provided with a slideway that limits the sliding of the sliding bearing 3 back and forth, and a button 2 that can push the sliding bearing 3 to slide along the slideway. The sliding bearing 3 is slidably arranged in the wire feeding cavity through a slideway. The gear 6 is rotatably arranged in the wire feeding cavity, and is fixedly connected with the drive output shaft of the motor 4. The sliding limiting direction of the slideway is the di...

Embodiment 2

[0028] Example 2: The structure is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is:

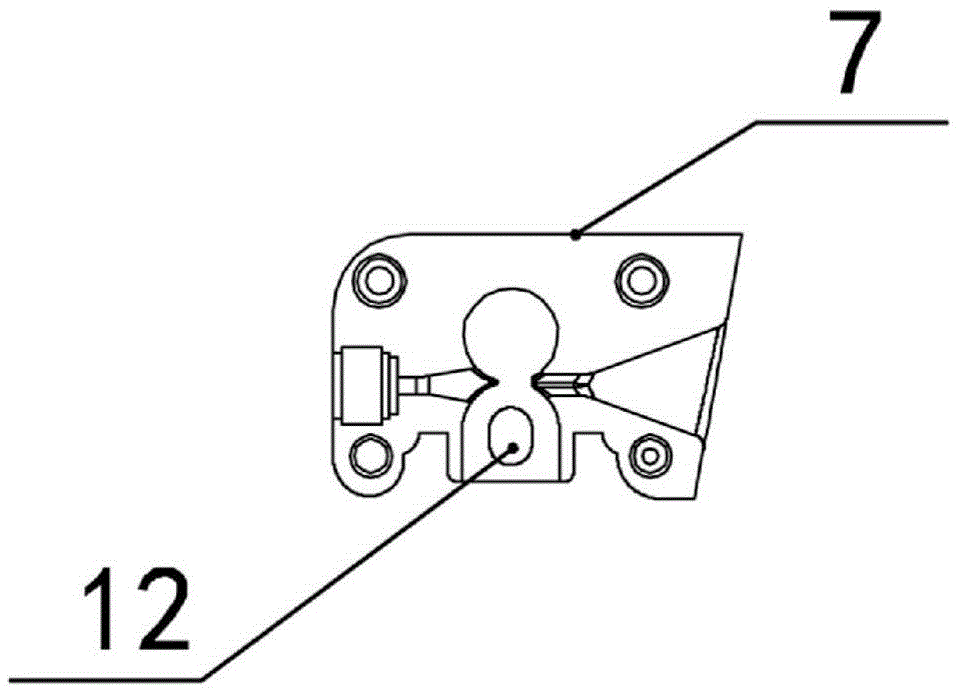

[0029] Specifically in this embodiment 2, the upper slide 10 is an upper slide groove provided on the inner surface of the upper fixing bracket 5 facing the wire feeding cavity; the lower slide 12 is provided on the lower fixing bracket 7 facing the wire feeding cavity The sliding groove on the inner surface of the body.

[0030] The upper end of the sliding bearing 3 is located in the upper sliding groove, and the lower end is located in the lower sliding groove. The sliding bearing 3 is slidably arranged in the wire feeding cavity along the sliding direction of the upper and lower grooves.

[0031] The groove bottoms of the upper chute and the lower chute are in the shape of a slender strip, an oval or a gourd.

[0032] Taking Example 1 as an example, the working process of the wire feeding device is: the consumable tray 13 is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com