A fully automatic wire feeding device

A fully automatic, wire-feeding device technology, used in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of no monitoring device, wire breakage, long wire path, etc., to ensure the quality of wire supply and wire feeding. The effect of short path and improved wire feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

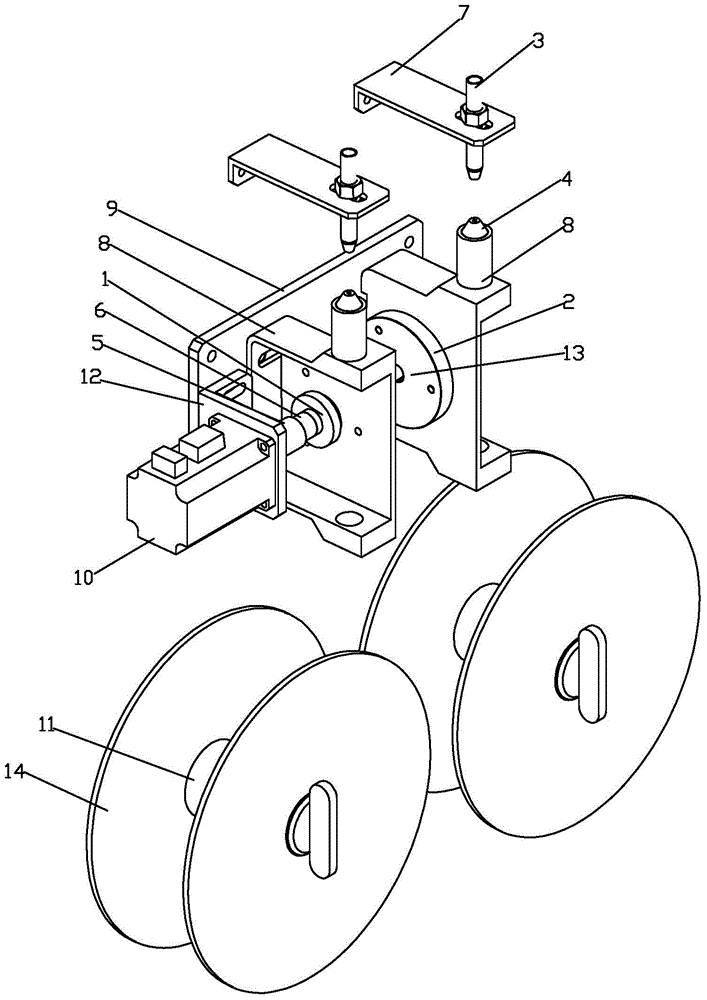

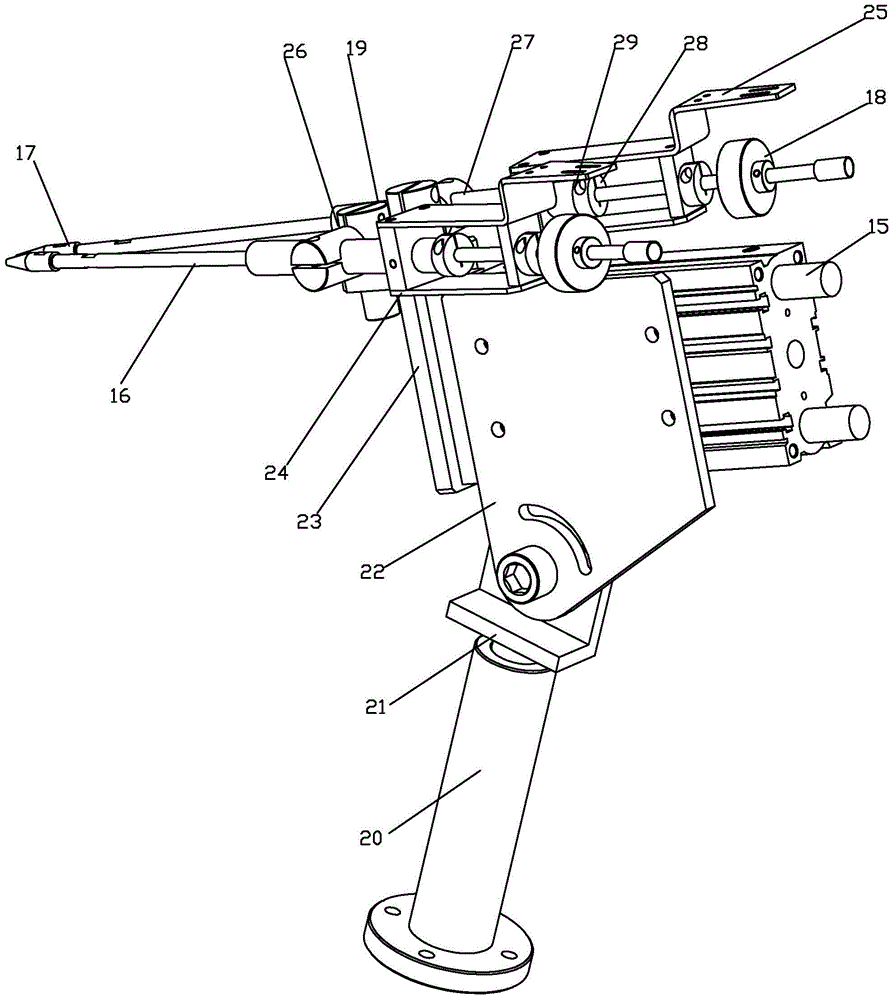

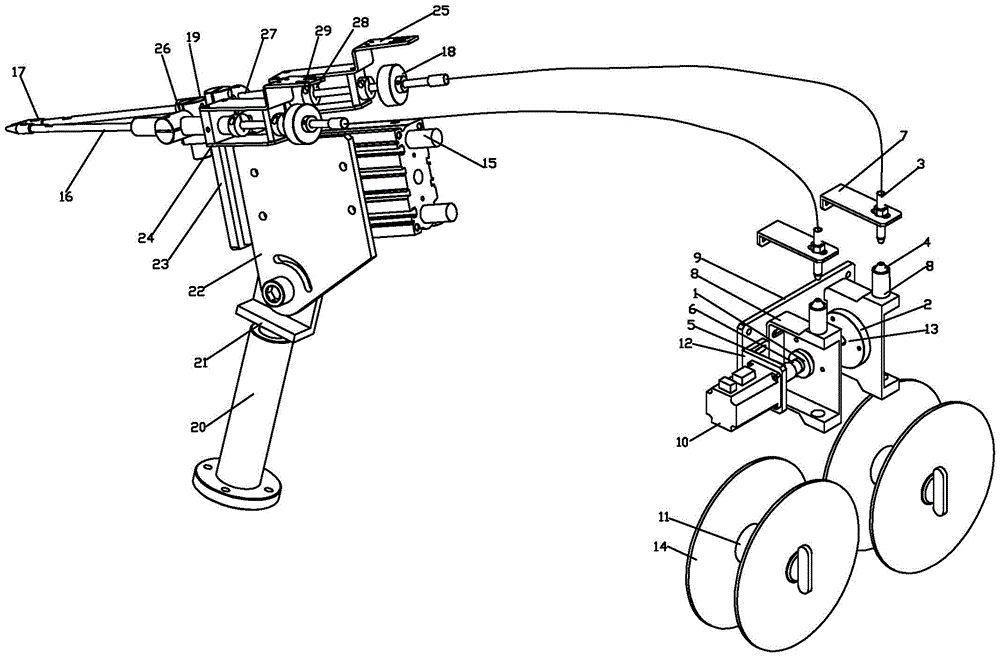

[0021] like Figure 1-3 As shown, the fully automatic wire feeding device of the present invention includes a wire guiding device and a wire feeding device. The wire guide device in the present invention includes a wire guide disc 14 and a wire feeding mechanism, and the middle part of the guide disc 14 is provided with a disc shaft 11 .

[0022] The wire feeding mechanism in the present invention comprises a wire feeding mechanism bottom plate 9, a motor mounting plate 12 and a four-wheel drive bracket 8 are installed on the wire feeding mechanism bottom plate 9, a servo motor 10 is installed on the motor mounting plate 12, and the wire feeding shaft 6 passes through The shaft device 5 is connected with the servo motor 10, the wire feed shaft 6 passes through the four-wheel drive bracket 8, and above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com